The Bryden Horseshoe

Company

Burkhardt, Roberta and Judy

Gemmel, ed., A Profile of the Burroughs, Catasauqua

Many

manufacturing firms in Catasauqua were inter-related through family and

marriage alliances. One such example was the Bryden Horse Shoe Company.

Oliver

Williams organized the Bryden in 1882. He had moved to Catasauqua two years

previously at the urging of long-time friend, David Thomas, and assumed the

position of president of the Catasauqua Manufacturing Company.

Williams

sought other uses for the iron products from his rolling mills and settled upon

the manufacture of Bryden Horse Shoes. He obtained the patent rights from

George Bryden of Hartford, Connecticut. Under Bryden's process the shoes were

completely formed under the blows of a heavy hammer, where as other shoes were

rolled and the heel and toe-caulks welded on by a blacksmith.

With

a capital investment of $60,000 Williams erected a one story brick building on

the north-west corner of Railroad and Strawberry Alleys. This lay adjacent to

the Union Foundry and Machine Shop, another company owned in part by Oliver

Williams. Joshua Hunt served as president; Oliver Williams,

secretary-treasurer; and Peter F. Greenwood, superintendent. Tilghman F.

Frederick subsequently replaced Greenwood, serving until 1889. Williams

equipped the plant with two forge hammers and employed approximately thirty

men. They produced a daily sum of 2-1/2 to 3 tons of horseshoes. In 1884 Oliver

Williams assumed the position of president.

So

successful was the plant that by 1888 expansion was necessary. The company

increased its capital stock to $100,000 and purchased land along the west side

of Front Street, straddling the Borough boundary with what would later become

North Catasauqua. Williams engaged Jacob Roberts, then part owner and

superintendent of Phoenix Horse Shoe Company, Poughkeepsie, New York, as

superintendent of the new facility. Roberts moved to Catasauqua in 1889 and

immediately began to build and equip the plant, eventually operating a complete

rolling mill plus bending and pressing irons for the exclusive manufacture of

horse and mule shoes. Roberts served as superintendent until his death,

November 18, 1905. He was succeeded by his son, William and later by Paul E.

Miller.

Always

alert to promising talent, Williams noticed a young, ambitious Englishman,

George E. Holton. At this time Holton was employed as an inspector, testing

tunnel segments cast by the Davies and Thomas Company during the construction

of the Hoboken Tunnel. Williams admired Holton's extensive knowledge of the

iron industry and employed him as traveling salesman for the new firm.

Holton

traveled nationwide, establishing sales agencies and securing orders. His most

noteworthy order involved the weekly delivery of a train-car load of horse and

mule horseshoes to the British Government during the Boer War, 1899-1910. This

allowed full employment at the facility and the Bryden emerged as one of the

largest industrial employers in

the

Lehigh Valley. George Holton also had the good fortune to marry the boss's

youngest daughter, Jessica.

Oliver

Williams died September 17, 1904. The Bryden's ownership passed to his three

daughters: Grace Kohler, Winifred Emanuel and Jessica Holton. George Holton

assumed the president's position and became the virtual owner of the plant.

Tilghman F. Frederick accepted the secretary's post until his death, March 31,

1909, when Holton's brother, H. Morley Holton was appointed.

George

Holton died February 10, 1913. His widow, Jessica, assumed the duties of

president and H. Morley Holton served as secretary and treasurer. The plant

grew steadily and by 1914 occupied 7 acres of ground. About 300 men produced a

daily tally of between 40 and 50 tons of horseshoes, making it one of the

largest plants of its kind in the world.

Subsequently

the Bryden Company faced the inevitable decline in the horseshoe market as cars

replaced horse-drawn vehicles. The Bryden, fortunately, attracted the attention

of a progressive competitor, the Phoenix Horse Shoe Company, Poughkeepsie, New

York--the same firm begun in part by Jacob Roberts in 1882. Placed in an

identical position, the Phoenix management decided on two courses of action: to

absorb the competition and to acquire new markets through diversification.

In

1928 the newly organized Phoenix Manufacturing Company acquired the Bryden

Neverslip Company, named to reflect the manufacture of winter horse shoes.

Phoenix later acquired other horseshoe facilities, but, except for the

Catasauqua plant, liquidated or moved the operations. The new owners found the

Catasauqua plant suitable for modernization and in 1939 discontinued the

rolling mill and converted to the production of commercial forgings and

flanges, thus becoming Phoenix's forging division. Demand for the products

remained strong. By 1953 the Catasauqua plant housed 21 board hammers, ranging

in size from 1200 pounds to 4000 pounds, plus a complete die room and

production machine shop.

Over

the next 25 years, the local Phoenix plant experienced several ownership

changes. In 1957 the Union Car Company bought the Phoenix Manufacturing

Company, all divisions and subsidiaries. In 1971 Trans Union Company, formerly

the Union Tank Company, sold all of the Phoenix facilities, except the newly

named Phoenix Forging Company, Catasauqua, to the Continental Steel

Corporation.

Trans

Union continued to improve the Catasauqua plant. Two large 6-station, 5-die

cold heading machines, capable of progressively forming parts from coil stock,

were installed. In 1977, the dilapidated wooden building surrounding the

machinery was replaced by a modern metal structure.

In

1981 the Marmon Group, Inc. purchased Trans Union and with it, the Phoenix

Forging Company. In 1985 Barco Industries of Reading, Pennsylvania bought the

Phoenix plant.

Today

the Phoenix Forging Company, Inc. operates within a 120,000 square foot,

one-story steel and concrete facility on a 7.5 acre site, Front Street. The 125

employees manufacture a diverse product line: tank flanges for above ground and

under ground storage tanks and pressure vessels; outlets under the trade name,

Trans-O-Cons for the petro-chernical industry; commercial forgings and striking

tools, hammers, hatchets, auto-body tools, etc. Current officers include Owen

W. Blum, president; John Rodgers, vice president, secretary and treasurer;

Larry Dildine, vice president of operations; and Nick Thee, comptroller.

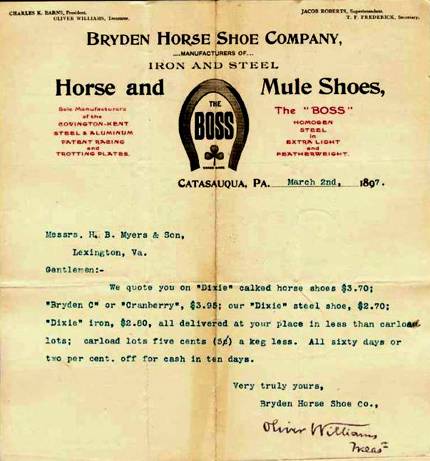

History of the Bryden

Horseshoe Works

Source:

Historic

Catasauqua Preservation Association, News Letter,

Fall 2014

Oliver

Williams, who was raised here, returned to Catasauqua in 1847 at the request of

his friend David Thomas to run the Catasauqua Manufacturing Company. Starting

as general manager, he served as president from 1879 to 1892, growing the

business into one of the best-known and largest merchant iron mills in eastern

Pennsylvania.

Williams,

looking for a way to use the iron products from his rolling plant, bought the

patent rights for the Bryden process from George Bryden of Hartford,

Connecticut. The Bryden technique made horseshoes with toe and heel caulks

completely formed under the blows of a heavy hammer making them highly durable.

Other machine-made shoes at the time were rolled, with heel and toe-caulks

welded on.

With

a capital investment of $60,000 Williams erected a one-story brick building on

the northwest earner of Railroad and Strawberry Alleys. This lay adjacent to

the Union Foundry and Machine Shop, another company owned in part by Oliver

Williams, located on the corner of Pine and Front. Williams, as

secretary-treasurer, Joshua Hunt, as president, and Peter F. Greenwood, as

superintendent, organized the first Bryden plant in 1882. The plant, equipped

with two forge hammers, employed approximately 30 men and produced a daily sum

of 2-1/2 to 3 tons of horseshoes. In 1884 Williams became president of Bryden

Horse Shoes. The plant was so successful that by 1999 the company purchased

land along the west side of Front Street for a new plant. Williams hired Jacob

Roberts, then part owner and superintendent of Phoenix Horse Shoe Company of

Poughkeepsie, NY as superintendent of the new facility. Roberts moved to

Catasauqua in 1889 and began to build and equip the plant, eventually operating

a complete rolling mill plus bender and pressing irons for the exclusive

manufacture of horse and mule shoes. Roberts lived in what is now the Capwell

home on the SW corner of Third and Strawberry.

Williams

hired a young ambitious Englishman, George E. Holton, who had extensive

knowledge of the iron industry, and employed him as traveling salesman for the

new firm. Holton traveled nationwide, establishing sales agencies and securing

orders. His most noteworthy order involved the weekly delivery of a train

carload of horse and mule shoes to the British Government during the Boer War,

1899-1910. This allowed full employment at the facility and the Bryden became

one of the largest industrial employers in the Lehigh Valley. George Holton

married William's youngest daughter, Jessica. When Williams died on September

17, 1904, Bryden 's ownership passed to his three daughters. George Holton

became president until his death February 10, 1913 when his widow became

president; his brother helped oversee operations. By 1914 the plant occupied 7

acres of ground and employed 300 men, producing a daily amount of horseshoes

between 40 and 50 tons, making it one of the largest plants of its kind in the

world.

In

1917 the business and property were sold to the Never Slip Co. of New

Brunswick. NJ, and continued operation under that name. As cars replaced

horse-drawn vehicles, the shoe market declined, however, Bryden attracted the

attention of a competitor, the Phoenix Horse Shoe Company of Poughkeepsie. NY.

Facing the same market decline for shoes, the Phoenix management decided to

absorb the competition and to acquire new markets through diversification. In

1928 the newly organized Phoenix Manufacturing Company acquired the Bryden

Never Slip Company. Phoenix later acquired other horse companies, but, except

for the Catasauqua plant, liquidated or moved the operations. Since the

Catasauqua plant was suitable for modernization, Phoenix discontinued the

rolling mill in 1939 and converted to the production of commercial forging, and

flanges.

Over

the next 25 years, the local Phoenix plant experienced several ownership

changes. Union Car Co. in 1957 and Trans Union Company in 1971, both of whom

continued to make improvements at the Catasauqua plant. By 1953, the facility

housed more than 21 board hammers, a complete die room, and a production

machine shop. Two large 6-station, 5-die cold heading machines capable of

forming parts front coil stock were installed. In 1977, a new modern metal

building replaced the car the wooden structure. The offices were relocated from

the building on Chapel into the main manufacturing building, and the old office

building sold.

In

1981, the Marmon Group of Chicago purchased Trans Union, and in 1985 sold the

Phoenix plant in Catasauqua to Barco Industries of Reading. Today, the Phoenix

Forge Group is nude up of the following companies: Capitol Manufacturing

Company, Phoenix Forging Company, Conduit Pipe Products Company. Phoenix

Hotform Company, Barco lndustries and CapProducts of Canada. The Phoenix

Forging Co. of Catasauqua continues to modernize, manufacturing forged fittings

for pressure vessels.

Early history of the

Site of the Phoenix Forge

Source:

Historic Catasauqua Preservation Association,

News Letter, Fall 2014

In

1795, John Philip Faust paid off his father Henry's mortgage on the 193.5-acre

farm located here along the Lehigh River and built a beautiful stone mansion on

the site of today's Phoenix Forge. His son Jonas inherited the farm, died a

year later, and passed on the family farm to his son, Paul. Unfortunately Paul,

who was only 24 at the time, inherited enormous responsibilities: the care of

his great-grandmother Catherine (resided in a small house along the west side

of Front St above Pine), his grandmother Barbara (lived in Stemton, aka Northampton) and his mother Susannah,

Jonas's widow, though Susannah later married Henry Breisch and lived at the

farm house at the corner of what is now Third and Bridge. Paul Faust began

selling off land to meet his obligations in 1840, the first recorded deed

transfer was to Owen Rice. Other historically significant sales were to

Catasauqua Manufacturing Co. (1868), St. Lawrence Church (1860) and cemetery

(1868), and the Fuller Grove Farm (1885), the later a 57 acre purchase by James

W. Fuller, which marked the end of Faust ownership. In 1905, the Lackawanna

Land Company, comprised of venture capitalists from the coal region and

Philadelphia, purchased the Fuller Grove farm acreage: their sales office for

lots was on the second floor of the POSofA building on Bridge St. After WWI,

much of this land still remained undeveloped and in 1940 a large section

reverted to Northampton County for unpaid taxes. These lots were purchased by

the Borough of North Catasauqua Park and War Memorial. The Faust farm straddled

what would become the dividing line between Lehigh and Northampton Counties,

the bulk lying within North Catasauqua.

Return to the Catasauqua Industries Index

About The Hopkin Thomas Project

Rev.

March 2010