CHAPTER 2: THE NEWCOMEN ENGINE

It has been noted that the SAVERY apparatus was

capable of being useful to a certain extent for the purpose of raising water

but, due to its limited lift, it was not an effective proposition for the mine

owner. With the advent of the proposals by THOMAS NEWCOMEN and his partners in 1705 there

was, indeed, hope that the need to clear deep workings of flood water would

soon be realised. Early experimentations with the introduction of steam beneath

a piston inside a cylinder, and the condensation of that steam by means of the

application of cold water to the exterior of the cylinder, did prove that the

pressure of the atmosphere alone could force the piston to the base of the

cylinder. Having discovered that this principle worked it was soon decided to

put it into practice by building a full sized engine to demonstrate its

operation properly. Consequently, the partners went on to construct the first

machine and this was a reality by 1712. Accounts concerning the venue of this engine

vary, with some authorities stating that it was erected 'near Wolverhampton',

and others saying that it was at Dudley Castle in the County of Staffordshire.

There is definite proof for the latter location as documentary evidence and an

illustration in the form of an engraving still exist.

After struggling for some time to make the engine work

continuously NEWCOMEN was surprised "to see the engine go several strokes, and very quick

together, when, after a search he found a hole in the piston which let the cold

water in to condense the steam in the inside of the cylinder, whereas before it

had always been done on the outside". This was the turning point in the

effectiveness of the invention for it rendered the exterior cold water jacket

unnecessary. From thereon NEWCOMEN manufactured his engines in accordance with

the design shown in DIAGRAM 'C' where all of the elements which comprise the

'Atmospheric Engine' are illustrated in sectional form.

THOMAS NEWCOMEN had put in about fourteen years of

development work before he achieved the success that was rightly due to him

when the Dudley Castle machine was erected in 1712. Some details concerning

this engine are interesting for it was quite a small affair when compared to

later units; it had a cylinder diameter of 21 ins, and it stood at a height of

7 ft. 10 ins. Its performance was satisfactory for it could operate

continuously at 12 strokes per minute to lift 10 Imp. gallons of water from a

depth of 153 feet at each stroke to discharge to a drainage adit linked to the

main shaft. Other engines soon followed the 1712 unit and machines are known to

have been erected at Whitehaven and Hawarden as early as 1715 and 1716 respectively. However, some problems ensued during

this period, for another engine supplied to Moor Hall Colliery, neai Leeds, at

about the same time did not seem to have been as successful as the previous

three and apparently, only lasted for some four years. In construction the Moor

Hall engine was similar to the others having a cylinder dimension of 23 ins,

and stroke of 72 ins, and being credited with a lift of 111 ft. to adit at 12

strokes per minute when working automatically, being increased to 15 strokes

wher controlled manually. NEWCOMEN spent considerable amount of time repairing

the Leeds engine and his partner, JOHN CALLEY, is reputed to have died nearby

at Austhorpe in 1717 whilst engaged upon these repairs. There has been some

dispute about the death of CALLEY at this time foi there is a record of a JOHN

CALLEY dying in March 1725 in Holland who was also an associate of NEWCOMEN.

The probable explanation for this is that the JOHN CALLEY who died in the Leeds

ares was the original partner, whilst the other death wat that of either his

son or nephew.

After

these beginnings, with the success of the NEWCOMEN engine being more or less

assured the apparatus soon became popular with mine owners and others and

although the cost of them a about £1,200 was astronomical at the time, there

was an obvious need for such equipment and customer were willing to pay the

price. The first engine for waterworks use was the unit constructed for the

YORK BUILDINGS WATERWORKS by the Strand in London which was erected in 1762;

this engine did attract some unwelcome publicity at the time for Londoners

objected to smoke pollution from it. Thi5 factor had not arisen before as the

engines wer usually supplied to mining areas where smoke and other pollutants were taken for granted in the

1700s. Very soon an export market was established for the NEWCOMEN engine on

the Continent, firstly with an engine being sent out to the city of Konigsberg

in Hungary to be followed with other examples supplied to what is now the Czech

Republic, and then to Belgium, Austria, Sweden, Spain and France. The Swedish

engine was originally mooted by Colonel JOHN O'KELLY, who possibly may have been an ancestor of the

writer, but his role in the proceedings has always been reported as being

'elusive'. The first NEWCOMEN engine to be built for the U.S.A. was erected at

the ARLINGTON COPPER WORKS in the State of Maine between 1753 and 1755; this

work was overseen by a member of the HORNBLOWER family, JOSIAH, and its cylinder still survives in the National

Collection at the SMITHSONIAN INSTITUTION.

Operation and Technical Details of the NEWCOMEN Engine

The operation of the NEWCOMEN engine and its technical

details make interesting reading in the light of modern technology, for at the

time of its inception and early usage many difficulties in the construction of

the component parts, the correct methods of erection and in the adjustments for

continuous running appeared. As with all new technology an industry devoted to

the building of the engines soon came into being, and many engineers appeared

to take advantage of the invention.

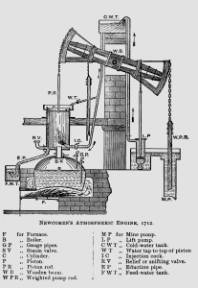

Diagram C ‑ Newcomen's 1712

atmospheric engine ‑ operation.

Referring to DIAGRAM 'C', the NEWCOMEN Engine

consisted of a boiler surmounted by the piston and cylinder, with the piston

rod being connected to a heavy wooden beam which rocked on trunnion bearings

situated on a specially strengthened outer wall of the engine house; at each

end of the beam were two 'arch‑heads' to which there were fixed link

chains. On each power stroke, atmospheric pressure forced the piston down to

pull on the 'in‑house' chain which in turn rocked the beam to lift the

pump‑rods attached to the 'out‑of-house' chain; when the power

stroke was spent the weight of the pump‑rods rocked the beam 'out‑ofhouse'

and carried the piston to the top of the cylinder again and then the cycle was

repeated.

Referring to the drawing, the method of operation in

detail was as follows: the Furnace F fired a 'haystack' boiler B to produce

steam at a pressure of about 5 psi. which flooded into the cylinder when the

piston was at the top of its stroke and the steam valve SV opened. When the

cylinder was filled with steam, the valve SV was closed and the water injection

cock IC was opened; this water condensed the stream in the cylinder to cause a

vacuum to be formed beneath the piston, which was then driven downwards by the

pressure of the atmosphere (14.7 psi.) to bring the beam 'in‑house' and,

hence, lift the pump rods which were connected to a pump bucket at the base of

the mine. When the piston had reached the bottom of its stroke any residual

water left in the cylinder was driven out via the eduction pipe EP to a

separate feed‑water tank, and any air in the system was released through

the 'snifter' or relief valve RV. This latter valve was so named by NEWCOMEN

because of

the curious noise that it made. By now the weight of the pump rods etc. was

sufficient to draw the piston to the top of the cylinder, and the beam was said

to be 'out‑of‑house'. Other apparatus shown in the drawing included

the lift pump, LP, to feed the cold water tank for injection and also to provide

a water seal on the top of the piston to prevent steam and vacuum losses.

Ancillary chain drives to operate the lift pump and a feed water pump were

placed in‑board of the arch‑heads and these were called 'little

arches'. At first all of the valves and cocks were operated manually and the

engine man had to go around opening and shutting them; firstly he would ensure

that the water seal on top of the piston was made, then he would open the steam

valve. When the beam came 'in‑house' after the steam valve had been shut,

and the injection valve opened, that injection valve would be shut and the

eduction valve opened to release the residual water He also had to try to

operate the try cocks on the gauge pipes on the boiler to ensure that water

levels were maintained inside the vessel. All of this was very labour intensive

and arduous and soon after its inception the NEWCOMEN engine was fitted with

automatic valve gear. The move towards automation came unexpectedly, so the

story goes. The popular theory is that an attendant, a boy name POTTER, tiring of the monotonous task

of operating all of the valves, connected them together in sequence with lines

of cord. In the manual form of operation the attendant had to be very wary in

case the piston hit the base of the cylinder, or allowed the piston to be drawn

out of the cylinder at the top of the stroke, allowing the beam to go 'out‑of‑house'

with disastrous results; with automatic operation, stops were fitted to prevent

either of the above mishaps and strong cords were fitted to operate the valves.

These cords etc. were gradually replaced with rods, catches and detents and in

1718 a Land Surveyor and engineer named BEIGHTON is thought to have formulated a coordinated

form of valve

gear when he erected a NEWCOMEN Engine at Oxclose. Incorporated with the valve

gear was another piece of equipment called the 'buoy' which ensured that

another power stroke was not made until the boiler had recovered sufficiently

to enable it to provide enough steam for the following cycle. Unfortunately

over a space of nearly three hundred years the stories of invention and

modification and their creators have become muddled; some credit HENRY

BEIGHTON with

the valve gear improvements, whilst other give the sole credit to NEWCOMEN and CALLEY;

the boy POTTER

has always

been credited with the invention of the 'Scoggan', or detent, but this is open

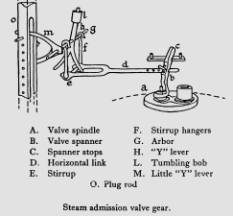

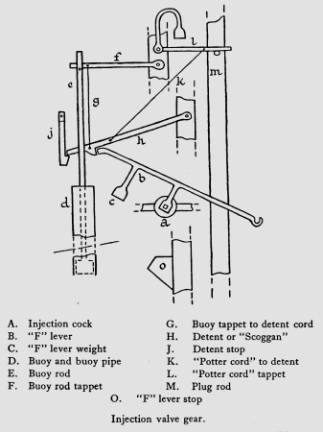

to discussion. Some details of the method of the operation of the valve gear

are shown in the diagrams on the next page which shows the steam admission gear

and the injection valve gear. With the atmospheric engine NEWCOMEN managed to hold a pressure of

6.4 psi.. continuously in the cylinder ‑ no mean feat at the time

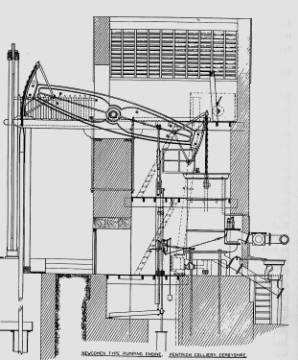

Fig. 6 ‑ The Newcomen atmospheric engine

built by Francis Thompson for Oakerthorpe Colliery in 1791. It was removed to

Pentrich Colliery in 1841 and worked, in total, for a period of 127 years.

Early Valve‑gear Systems used on NEWCOMEN Engines

The Steam Admission Valve:

When NEWCOMEN engines were originally fitted with the

means for working automatically, the arrangements were constructed according to

the drawings depicted on the right. For the admission of steam, the valve at A

oscillated from side to side to close or uncover a port in the pipe from the

boiler to the cylinder; this was actuated as follows: As the Plug Rod O rose and fell, a pin moved

the little 'Y' lever M up and down to rock the arbour G which in turn imparted a motion to the 'Y'

Lever H

which had a weight at its extremity to enable it to go over centre. This allowed

the stirrup E to move horizontally and pull the 'spanner' up against one of the stops

at C. The

'spanner' was attached to a spindle which in turn was fixed to the admission

valve. This system allowed the position of the beam to determine the admission

of steam.

The Injection Valve:

This system also worked on the plug rod at M and, as it descended, it

depressed the end of the 'F' Lever C until it reached the closed position where it was

retained by the detent H. At this point the 'buoy' took over, for the steam valve having opened

and filled the cylinder as the engine went 'out‑of-house', the buoy

precluded another power stroke until the boiler had recovered. When the steam

dome on the boiler became re‑filled, the pressure inside allowed the buoy

to rise and release the detent rod and allow the 'F' Lever to fall by gravity

and so open the injection cock. The 'POTTER CORD' allowed manual over‑ride

as well as controlling the detent

Subsequent Historical Data

concerning the NEWCOMEN Engine.

Following the death of THOMAS SAVERY on the 15th May in 1715, his

patent rights were passed on to his wife, MARTHA, who by the good offices of JOHN

MERES, the

Secretary of the Worshipful Company of Apothecaries, was able to have them

invested in a Joint‑Stock Company which was known by the title of

"The Proprietors of the Invention for Raising Water by the Impellant Force

of Fire". The governing body of this organisation was known as the

"Committee of the Proprietors" and amongst others, THOMAS NEWCOMEN

was an important

member; most of the other personalities involved in this committee had

influence in the City of London. These Proprietors sought to contain the Patent

and licence its use to selected engineers and engine builders and thus preserve

a monopoly; to this end an advertisement appeared in the LONDON GAZETTE for the

11th/14th of August 1716 which gave notice that 'any person desirous to treat

with the Proprietors for such engines' should repair to a coffee‑house in

Birchin Lane to see one of the Proprietors, EDWARD ELLIOT, every Wednesday to discuss

terms.

Of course this monopoly exerted a stranglehold on the

industry in the same way that BOULTON & WATT managed to do later on in

the 18th Century and H. J. LAWSON and GEORGE B. SELDEN did to the motor industry at

the end of the 19h Century. However, as the Patent expired in 1733, the power

of the Proprietors was curtailed as the invention came into the public domain

and the payment of royalties ceased. Nevertheless the Proprietors did have a

good run for their money, for in the period between 1712 and 1733, some 110

engines had been erected at home and overseas and the NEWCOMEN system became an

established form of effective motive power.

Improvements to the

NEWCOMEN Engine:

It has been noted previously that although the

NEWCOMEN engine was, indeed, 'fit for purpose' it was inefficient in the use of

fuel and water and, therefore, there was a great need for improvement.

Notwithstanding that the invention was the 'wonder of the age' and that its

appearance in the 18th Century was akin to the Moon Landings in 1969 during the

20th Century, there was, as with the Moon Project, a hiatus following the lapse

of the Savery patent during which little or nothing was achieved by way of

advancement.

One of the main problems that had to be overcome was the

restriction on cylinder diameter occasioned by the use of brass for the

castings. In the early days of the NEWCOMEN engine, brass could be machined

more accurately than other materials but it restricted the size to diameters

below 36 ins. This persisted to the 1720s until ABRAHAM DARBY perfected the

casting of engine cylinders in iron at his COALBROOKDALE IRON WORKS. For a

period of forty years the COALBROOKDALE concern enjoyed their own monopoly of

cylinder casting and by 1761 they were able to produce cylinders as big as

74-1/2 ins, diameter by 120 ins, in length. The demand for these iron cylinders

started slowly but it soon accelerated and, with the appearance of the BOULTON

& WATT engine in the 1770s and 1780s, the demand for larger cylinders

weighing over 6 tons each outstripped the resources of the COALBROOKDALE firm.

It was left to JOHN SME TON, the builder of the Eddystone

Lighthouse, to effect real and lasting improvements to the NEWCOMEN engine.

Whereas earlier engineers had tended to work empirically, SMEATON introduced an element of

science into his modifications. The methods of empirical working did stultify

improvement and SMEA TON's work enhanced the performance of the atmospheric

engine. JOHN SMEATON formulated a system of measurement of the performance of engines which

he called the 'duty' this measurement was the amount of water in millions of

pounds (a.v.d.) that could be raised one foot high per bushel of coal (a bushel

weighing 84 lbs.). This standard enabled one engine to be compared to another

to ascertain relative efficiency. He selected some NEWCOMEN engines at work on Tyneside

for comparison and he found that loadings and overall performance varied

greatly ‑ a well loaded engine from point of view of piston pressure did

not necessarily point to the best duty achieved and he found in his studies

that a 60 ins, machine performed better than one having a cylinder diameter of

75 ins.! The former engine achieved some 3 h.p. better than the latter when translated

into horse‑power figures. The reason for this discrepancy lay in the

degree of accuracy of manufacture of the components, and SMEATON discovered that some of the

cylinders allowed the piston to be slack in the bore, whilst others were tight;

valve gear did not admit the right quantity of steam to work effectively and so

on. Other factors were present such as too short a stroke, boiler grates

pitched too low to provide the correct heat values to be extracted from the fuel whilst too much water accumulated

on top of the piston to cause excessive cooling. SMEATON was associated with another

famous ironworks of the time which was the first such enterprise in Scotland ‑

the CARRON IRONWORKS ‑ noted for their 'potbellied' coke stoves today.

This foundry went into production in 1760 and SMEATON designed the plant there; one

of the tools that he introduced was an accurate cylinder boring mill which

could produce a truly circular bore. The entrance of the CARRON IRONWORKS into

the fray ended the COALBROOKDALE monopoly.

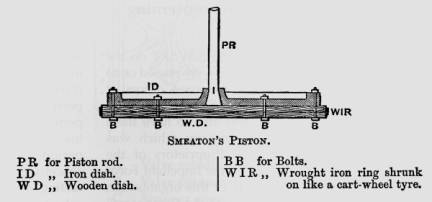

Amongst the improvements that SMEATON effected were his special form

of piston, shown in Diagram 'D', an improvement on the NEWCOMEN type which had

consisted of a flat plate with a broad strip of leather screwed to it and

turned up at the sides some two or three inches in the cylinder. This piston

gave considerable trouble owing to its irregular fit which caused leakage and

the fact that the leather was often cut up being then worse than useless. SMEATON

applied

scientific data to the admission of steam and the amount of injection water

needed to cause condensation in the cylinder with the wooden underside of his

piston preventing waste in this direction. He introduced a feed‑water

heater system and increased the flexibility of the working strokes by means of

regulation of steam volumes rather than shortening the stroke and replacing the

'buoy' system with a 'cataract' which allowed a water trough and cup system to

vary the weight operating the 'F' Lever which controlled the injection cock.

When the engine worked at maximum power the cataract was put out of use, but as

loads decreased due to there being less water in the mine, the cataract could

be linked to the cycle to regulate the number of strokes per minute by

adjusting the amount of water held in the cup to achieve a variable weight

effect. SMEA TON adopted a hemispherical cylinder bottom and a laminated timber beam with

its trunnions set at its mid‑point instead of below as had been the norm

when timber baulk beams were used.

Diagram D.

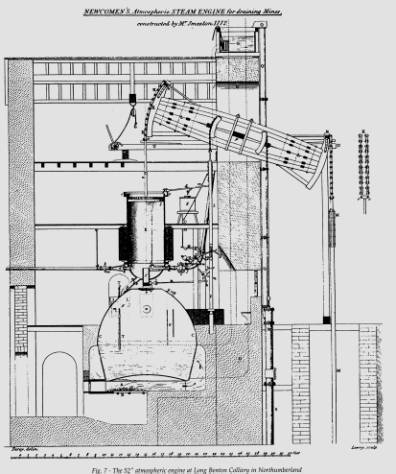

All of SMEATON's improvements were embodied in his 52 ins,

engine erected at the LONG BENTON COLLIERY, Northumberland in 1722 (Fig. 7).

This engine worked at 12-1/2 strokes per minute on a mean effective pressure of

7.5 psi. to return a duty of 9.45 millions, whereas the best recorded duty

figure that he had found on Tyneside was only 7.44 millions. SMEATON then built a number of other

engines that included his improvements and these were located at Chacewater in

Cornwall where he built a 72 ins, machine in 1775, at Kronstadt in Imperial

Russia where a 66 ins, engine was supplied for emptying docks, and several

others that were used variously in mines and waterworks.

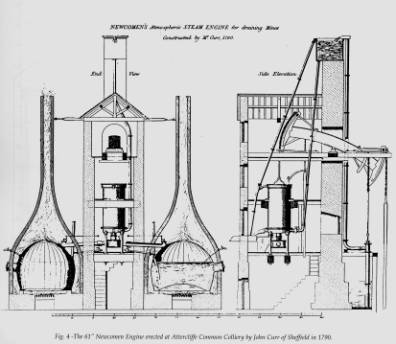

Another improver of the atmospheric engine was one JOHN

CURR of

Sheffield who decided to locate the boilers remotely to obviate the need to

mount the cylinder over the boiler steam‑dome. JOHN CURR wrote a book

entitled "The Coal Viewer & Engine Builder's Companion" which was

published in 1797 and following this he erected a 61 ins, engine at Attercliffe

Common Colliery in 1790, (Fig. 4), which embodied his principles. For this

plant he used two boilers located in outhouses alongside the engine-house and

these were connected together by means of a common steam pipe which joined in a

chest beneath the cylinder; this configuration enabled CURR to build a more compact engine

house which provided a greater degree of support for the cylinder and its

ancillary equipment. Previously, when the cylinder was mounted atop the boiler,

there were fractures in steam pipes and failures in the jointing because the

cylinder, not being adequately supported, tended to flex excessively at each

stroke and cause such problems. Another improvement made by CURR was to increase the elevation

of the injection water cistern, placing it on an extended wall of the house to

be situated well above the roof. The stroke of the Attercliffe Common Colliery

engine was 81/2 ft. and it made 12 strokes per minute to return a duty of 9.38

millions

Other modifications to the original NEWCOMEN style of engine are noteworthy and: they include the introduction of the ‘pickle-pot’ condenser, the replacement of the link chain by the pitch–chain (like a bicycle chain with plates and rollers) on the arch heads and the fitment of drop‑valves and and sliding valves in place of the plug cocks. The 'pickle‑pot' condenser was placed below the cylinder and it was in direct communication with it through a large diameter pipe; cold water was injected into the 'pickle‑pot' instead of into the cylinder and later on in the cycle the incoming steam blew the condensate and any air present out via a non‑return valve that was loaded at about 2 p.s.i. This method was not too efficient though it did possess the advantage that when the steam was admitted into the cylinder it was not exposed to so great a volume of condensate as hitherto. Messrs. BOULTON & WATT always considered the 'pickle‑pot' condenser to be an infringement of their 1769 Patent, though they are never recorded as having resorted to litigation to suppress its use. However, many features of the improved engine as built by BOULTON & WATT were incorporated in atmospheric engines erected after the lapse of the 1769 Patent in 1800, and these included the use of the separate condenser, the fitting of the WATT water cataract governor together with drop and sliding valves and the replacement of the wooden beams with cast‑iron units having the WATT parallel motion at the piston rod end.

Notes on Important NEWCOMEN Engines and those Existing Today

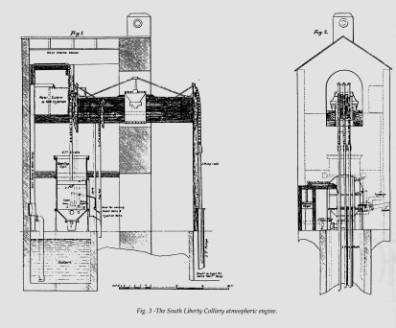

One of the most famous NEWCOMEN Engines to be

documented was that erected at the South Liberty Colliery which was owned by

the ASHTON VALE IRONWORKS of Bedminster in Bristol. This engine, which is

depicted in Fig. 3, was the last atmospheric unit to operate in the West of

England and it was one of the longest lived, working from about 1750 until 1900

when, unfortunately, it was scrapped. Luckily it was extensively documented by BRYAN

DONKIN M.I.C.E.. in the journal

"ENGINEERING" for their issue of the 25th October 1895. In the

article, which was derived from fieldwork carried out by H.W. PEARSON M.Inst. Mech. E. in the

May of that year, there were several supporting photographs of the old engine

together with drawings (Fig. 3) and, interestingly, an Indicator diagram.

The South Liberty Engine was seen in the photographs

to have retained its massive, wooden, laminated beam made on the SMEATON

pattern and which measured 24 ft ins length by about 4 ft.

in depth as well as having pitch‑chains on the arch-heads

instead of link‑chains; the cylinder dimension was 66 ins, and it had a

stroke of 6 ft. This cylinder was designed with a conical bottom to gain ease

of condensate drainage in a similar manner to SMEATON's hemispherical shape,

and it weighed 6 tons. The Indicator Diagram, alluded to previously, recorded a

boiler pressure of 2.3 p.s.i. and a mean effective pressure of 9.5 p.s.i. at a

rate of 10 strokes per minute ‑ this gave a Horse Power rating of 52.72.

When one considers the weight of the engine in total, the boiler, the pitwork

and the pumps, the horse power per ton figure is minimal, but nevertheless,

these engines did do their work well considering the time at which they were

made. Over its 150 years of use, the South Liberty Engine worked for about 5

hours per day, for 6 days a week. The engine‑man who was driving it in

1895 had driven it since he was a boy, his father and grand‑father having

driven it before him.

Another important machine was the 72 ins. Chacewater

engine erected by JOHN SMEATON in 1775 which has been mentioned previously. It was

one of the most powerful NEWCOMEN prime movers that had been made up to that

time and it was the largest such engine to work in Cornwall with a stroke of 9

ft. and going at 9 strokes per minute it developed 76 h.p. It was fitted with

SMEATON's laminated wooden beam which measured 27 ft. 4 ins, in length, by 2

ft. wide and 6 ft. 2 ins, deep at its centre; this beam was made up from twenty

pieces of fir measuring 12 ins. x 6 ins, in section and all bolted together.

The Chacewater engine worked three 16-1/4 ins, pumps in series which drew water

from a depth of 306 ft. to adit

level. Apparently it did not last long as an atmospheric engine for in 1778 it

was re‑built by JAMES WATT being fitted with a new 63 ins, cylinder which was

cast by WILKINSON; the original cylinder was retained and was used as an outer casing for

the new one.

From research that was conducted during the latter

half of the 20th Century, it appears that 1454 NEWCOMEN or atmospheric engines

were constructed world‑wide by the end of the 18th Century just prior to

the expiry of the BOULTON & WATT Patent in 1800. If one counts the two

rotative units that are preserved in Scotland and in the U.S.A., only seven

survive to the present day.