The Steam Engine

of

Thomas

Newcomen

L. T. C Rolt & J. S.

Allen

Moorland Publishing

Company

Hartington

Science History Publications/

USA

New York ‑-1977

COPYRIGHT NOTICE

All rights reserved. No

part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise, without the prior permission of Moorland Publishing

Company.

Published in Great

Britain by

Moorland Publishing

Company,

The Market Place,

Hartington,

Buxton, Derbys, SK17 OAL

First published in the

United States by

Science History Publications/USA

a division of

Neale Watson Academic

Publications, Inc.

156 Fifth Avenue, New

York 10010

Printed in Great

Britain by

Wood Mitchell & Co

Ltd, Stoke on Trent.

Ed. The following excerpts from Chapter 5,

Pages 89 – 110 give detail not found in other publications. J.McV Oct

2006

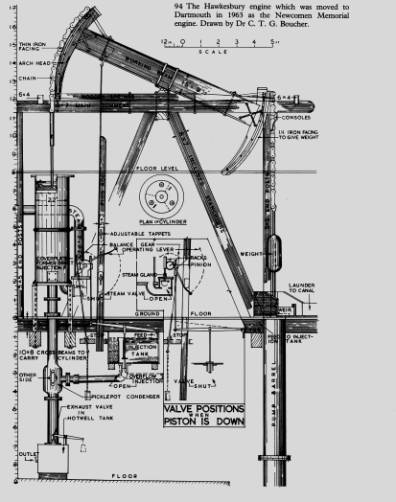

Fig.

17

Fig.

21

Fig.

94 The Hawkesbury Engine

CHAPTER 5

Technical Developments 1712-33

In

order to present the story of Newcomen and his engine as clearly as possible a great

deal of technical detail has been omitted from the preceding chapters. Such

detail is essential, however, to any assessment of Newcomen's achievement

because so many conflicting statements have been made as to how, and by whom,

certain features of the engine were developed. Quite apart from the need to pay

Newcomen his due, the story of how men, who were quite ignorant of the nature

of steam or the laws of thermodynamics, groped their way to success by sheer

practical ingenuity and tenacity of purpose is a fascinating one.

To

appreciate to the full the achievement of Newcomen and his associates, the

reader must use his imagination, forget his twentieth‑century background

and try to think himself back into those far‑off days. Such an

imaginative effort is essential if the error of hindsight is to be avoided,

because the solutions of many of the problems with which Newcomen grappled now

seem so obvious as to be self‑evident even to those who are not

technically minded. Even some of Newcomen's contemporaries and immediate

successors made this same mistake, so fatally easy to be wise after the event.

The most brilliant inventions are those which seem obvious once they have been

explained or demonstrated. 'Why, I could have thought of that', we say with a feeling

of envy and mortification, and it is clear from their writings that both

Desaguliers and Triewald reacted in this way, convincing themselves that they

could have done better than Newcomen had they chosen to bend their minds to his

problems.

Next

to the principle of injecting water into the cylinder to create a vacuum, the

most significant feature of the Newcomen engine was the valve gear, or 'working

gear' as it was called, which made it self‑acting. No early writer awards

Newcomen any credit for this valve gear and the only legend about his engine

that deserves to be called popular would have us believe that the valves were

worked by hand until a boy, tiring of this monotonous task, connected their

handles by strings to the beam. There may be a grain of misunderstood truth in

this legend as we shall see presently.

Farey, in his Treatise on the Steam

Engine, summarizes the

evolution of the valve gear as follows:

At

first the valves were opened and shut by hand, and required the most exact and unremitting

care of the attendant, to perform those operations at the precise moment; the

least neglect or inadvertence might be ruinous to the machine, by beating out

the bottom of the cylinder, or allowing the piston to be wholly drawn out of

it. Stops were contrived to prevent both of these accidents; then strings were

used, to connect the handles of the cocks with the lever [ie the balance beam]

so that they should be turned whenever it reached certain positions. These

strings were gradually changed and improved, into detents and catches of

different shapes: till at last, in 1718, Mr. Beighton, a very ingenious and

well‑informed engineer, simplified the whole of these subordinate

movements, and brought the machine into the form in which it has continued, to

the present day, without any material change.

Stuart, in his History of the Steam

Engine, goes further

than this. His plate entitled 'Newcomer's Engine' depicts an engine with hand‑operated

valves, while the next figure showing an engine with self‑acting valve

gear is headed 'Beighton's Engine'. His accompanying text reads:

The

mechanism for opening and shutting the cocks also remained perplexed by catches

and strings, until Mr. Henry Beighton, an engineer extensively employed in the

construclion of mining machinery, erected an engine at Newcastle‑on‑Tyne

in 1718, in which all these "cock‑boys" and complications of

cords were superseded by a rod suspended from the beam, which operated on a

mechanism invented by him called hand‑gear: a contrivance, with some slight

mod)fications, employed in engines of the present day.

Although

it is not possible to back the statement with positive proof, it is safe to say

that the hand‑operated valves referred to by Farey and illustrated by

Stuart belong to the experimental period before 1712. From that date forward

Newcomen's engine had the self‑acting valve gear evolved by him and his

assistant Calley and differing only in one important respect from that which

was later standardized and used with only minor variations down to the end of

the eighteenth century. This one

important difference accounts for the references to catches and strings as

well as for the legends about the ingenious 'cock boy'. The fact that these

references and legends are woefully misleading is due to a failure to

understand the difficulties— some of them due to lack of knowledge and

experience—encountered by Newcomen at the outset and the way he met them.

Before these difficulties and Newcomen's solutions to them can be understood,

it is essential to consider two things: the adequacy of the boilers used on

Newcomen's first engines and this method of calculating the work these engines

could perform.

It

will be recalled that when Nicholas Ridley proposed to erect a second engine at

his Byker colliery with a 33in cylinder the inventors, presumably Newcomen and

Calley, refused to undertake the project on the grounds that so large a

cylinder could not be supplied with sufficient steam. Commenting on this

refusal, Triewald writes:

The

cause of this conclusion was the false principles concerning the steam which

the inventors harboured in their minds according to which the steam rises or is

generated by the boiling water in proportion to the quantity of water in the

boiler. In consequence their boilers were made very high, as demonstrated by

the Stafford [Dudley Castle] engine, the boiler of which is higher than its

width. It is thus evident that the inventors do not know that the boiler must

be given a suitable shape. Neither did they know that the flames should be

allowed to play all around the side of the boiler as well as on the bottom....

Although

Triewald was a conceited young man and apt to be wise after the event, there is

no doubt that in this case his criticism was valid. It may seem obvious to us

that the steam generating capacity of a boiler depends on its heating surface

but this was by no means obvious in 1712. To suppose that it was only necessary

to increase the quantity of boiling water in order to obtain a proportionate

increase in the volume of steam produced from it was then a perfectly

understandable

error. Moreover, although Triewald appreciated the need to increase the heating

surface, this conclusion was purely empirical and boilers continued to be built

on an empirical basis for more than sixty years. The first Watt engines were

under-boilered and this defect led Watt to work out, for the first time, a

desirable ratio between boiler heating surface and cylinder volume. He

specified four square feet of heating surface per cubic foot of cylinder

volume.

The type of boiler used by Newcomen consisted of a

cylindrical copper vessel with a concave bottom directly above the furnace.

This was surmounted by a hemispherical steam dome of lead. The diameter of this

dome was greater than that of the copper cylinder below, the upper portion of

the latter being flanged outwards at right‑angles and then turned upwards

again in order to form a circumferential seam with the lead dome. It thus

resembled a haystack in crosssection and it became know as a ' haystack'

or 'flange' boiler, sometimes also called a 'balloon' or 'beehive' boiler. This

was certainly the type of boiler supplied initially to the Whitehaven engine,

although Spedding stated that it was the first of its type that Newcomen and

Calley ever had and they did not approve of them as much as those without

flanges. The brickwork enclosing the furnace was carried upwards round the

boiler and sealed against the lead dome plates. This arrangement left an

annular space beneath the dome and through this the hot gases from the furnace

circulated before passing up the chimney stack. The proportions of the boiler

were such that at working level there was but little depth of water upon the

copper 'roof' of the annular flue and this made it vulnerable in the event of

mismanagement. Although at an early date, high and low level try‑cocks

were provided so that the water level could be checked, attendants all too

frequently allowed the level to fall low with the result that the copper 'roof'

overheated and this led to the failure of the copper‑lead seam at its

circumference. The Austhorpe engine is said to have burned out four boilers in

this way in as many years. The first boiler at Whitehaven suffered the same

fate and had to be repaired first with lead and copper patches and then lined

all round with lead held on with lead nails. Although the eventual substitution

of wrought‑iron plates for copper and lead boiler less liable to suffer

from overheating, what was known as the 'tun' boiler came to be favoured by

later builders. Instead of the angular construction of the Newcomen 'haystack',

the lower portion of the tun boiler was cylindrical, tapering down from the

diameter of the steam dome to that of the concave bottom plate immediately

above the furnace. This entailed a certain loss of heating surface, but this

sacrifice was offset by altering the proportions of the boiler and its furnace

and flues. The second boiler at Whitehaven was made from iron plates with a

lead top and supplied by Stonier Parrott in 1717. It was reported as being

broader at the bottom and narrower at the top than the first boiler. This was

to give trouble in service at the junction of the iron and lead and the iron

corroded externally in this area. As early as March 1717 Mr Calley had

commented that 'he approved very well of iron boilers' indicating their use

elsewhere prior to this time.

So ingrained in us is the importance of a

large heating surface that modern diagrammatic representations of the early Newcomen

engine almost invariably depict a haystack boiler of a diameter exceeding its

height. By contrast, Barney's engraving of the Dudley Castle engine shows a

brick furnace and boiler casing of considerable height in proportion to its

diameter. It is particularly interesting to note that Barney shows the firehole

door in an impossible position above an arched access doorway to the ash-pit so

high that the fireman depicted in the foreground could walk through it without

stooping. Without the aid of a stepladder he would have had to be a gymnast to

put coal on the fire and would certainly need the 'little Bench with a Bass to

rest when they are weary' which, according to Barney's key, was thoughtfully

provided. This odd aspect of the drawing may be due to Barney's method of

showing the ash hole and engine‑water pump below the engine‑house

floor. The engine man is standing at the firing‑floor level but this part

of the drawing is moved forward to permit the lower level to be seen. Barney's

accompanying key tells us that the boiler was 6ft 1 in high but that the

diameter of the bottom plate was only 4ft 4in. Barney also gives the capacity

of the boiler as 'near 13 Hogsheads', this being the equivalent of

approximately 680 imperial

gallons. Having regard to the srr.all heating surface available, this was an

immense volume oi water and Barney’s figures thus corroborate Triewaid's

criticism of the Oucley Castle engine. It is clear that: as he says,

Newcormen did believe at this time that if he increased the

volume of water in a boiler its OUtpilt of

steam would increase proportionately . The full significance of this will

appear presently.

It is also interesting to note that the

von Schonstrom drawings of the Konigsberg engine show a plain boiler without

flanges.

The valve or 'regulator' that controlled

the admission of steam from the boiler to the bottom of the working cylinder

was mounted in the top of the steam dome and it resembled the type of valve

used by Savery on his later engines. It consisted of a fan‑shaped brass

plate which, moving to and fro horizontally, alternately covered and un‑covered

a steam port formed in a second brass plate rivetted into the top of the

boiler. On some engines the moving plate was held to its port face by a flat

steel spring, bridging the steam orifice below and bearing against a boss

formed on the lower surface of the plate. From the fixed brass plate in the top

of the boiler the steam pipe extended upwards to meet in a butt joint a pipe of

the same diameter passing through the centre of the cylinder bottom. This butt

joint was wrapped, first with canvas covered in white lead and oil, then with

sheet lead and finally bound tightly with cord. This primitive method of

jointing persisted for years despite frequent failures caused by movement of

the cylinder while the engine was working under load.

The vertical spindle of the moving sector

valve was tapered like the barrel of a plug cock where it passed through the

fixed brass plate in the boiler top and it was ground into a taper seating

formed in the latter in order to keep it steam‑tight. To the squared end

of this spindle a spanner was attached which could be worked to and fro by a

linkage arranged as follows. First there was pin‑jointed to the spanner a

horizontal link called the 'stirrup' because it was so shaped at its opposite

end. The forked ends of this slirrup were supported by two vertical links,

harlging loosely from a horizontal arbor which they shared with two levers

called the i' lever and the 'little Y'. Both were fixed at their common axis.

The Y lever was in the shape of that letter inverted and it carried a weight or

tumbling bob on its upper end. As it rocked on its arbor and the weight was

thrown over centre, its two lower arms alternately struck the crosspiece of the

stirrup and thus opened and closed the valve, the action of the weight ensuring

rapid and positive action. The plug rod which hung from the beam imparted this

rocking motion to the arbor by means of the little Y lever. Pegs in the plug

rod alternately raised and depressed the arms of this little Y as the rod rose

and fell. The valve spanner itself was provided with positive stops and there

were two methods of adjusting the motion. The pegs in the plug rod could be

moved into alternative holes, while a series of holes in the arm of the stirrup

enabled the pin‑joint by which it moved the spanner to be adjusted

similarly. This type of steam valve and its operating linkage persisted almost

unchanged for many years withonly detail refinements and it is safe to credit

its inception, not to Henry Beighton, but to Newcomen and Calley. The design of

the valve itself may have been derived from Savery, but the ingenious self‑acting

gear was entirely original.

The admission of

injection water to the cylinder was controlled by a simple plug cock. To the

designer of the steam admission gear it would have been a simple matter to

develop a similar linkage to actuate this cock from the plug rod, but Newcomen

did not do this for two closely associated reasons: the limited steam

generating capacity of his boiler and the excessive load he imposed on the

engine.

The admission of

injection water to the cylinder was controlled by a simple plug cock. To the

designer of the steam admission gear it would have been a simple matter to

develop a similar linkage to actuate this cock from the plug rod, but Newcomen

did not do this for two closely associated reasons: the limited steam

generating capacity of his boiler and the excessive load he imposed on the

engine.

Desaguliers,

who was doubtless supplied with the information by Henry Beighton, has this to

say about Newcomen's method of estimating the power of his engines: Mr

Newcomen's Way of finding it was this: From the diameter [of the cylinder]

squar'd he cut off the last Figure, calling the Figure on the left Hand long

Hundreds, and writing a Cypher on the right Hand, call'd the Number on that

Side, Pounds; and this he reckon'd pretty exact as a Mean, or rather when the

Barometer stood at 30 and the Air was heavy. N.B. This makes between 11 and 12

pounds upon every superficial round Inch. Then he allow'd between 1/3 and 14

Part for what is lost in the Friction of the several Parts and for Accidents:

and th~is will agree pretty well with the work at Griff Engine, there being

lifted at every stroke between 2/3 and 3/4 of the weight of the atmospherical

Column pressing on the Piston.

This

works out at a mean effective pressure of 9-1/2 1b/in2, an optimistic figure

bearing in mind that the atmospheric pressure employed could not exceed 14

lb/in2. Seventy years later the cautious Watt, although he was using steam at a

pressure slightly exceeding that of the atmosphere, allowed a mean effective

pressure of only 5 lb/in2 on his first rotative engines. The figure of 9-1/2

lb/in2 adopted by Newcomen meant that his first engines were so loaded that

their working depended on the creation of a high degree of vacuum below the

piston.

When

the engine had made its power stroke, or 'come into the house' to use the

current engineman's expression, the piston was returned to the top of the

cylinder by the weight of the descending pump rods at the other end of the

beam. So far from being asssisted in this motion by the incoming steam, the

pressure of the steam above atmosphere being negligible, the piston in its

ascent actually helped to draw the steam from the boiler into the cylinders.

The steam-generating capacity of the first boilers was so inadequate that the

sudden extraction of so great a volume of steam might literally have the effect

of sending the boiler 'off the boil'. If, therefore, water was immediately

injected into the steamfilled cylinder so that the engine made another

power stroke, the piston would once again be returned by the pump rods but

little or no steam would follow it because the boiler had not had time to

recoup. This, of course, would bring the engine to rest because in the absence

of steam no vacuum could be created. Faced with this problem Newcomen decided that the solution was to

regulate the working capacity of the engine in accordance with the steaming

capacity of the boiler.

This

solution took the form of a contrivance called a buoy. This was a small buoy

floating upon the surface of the water in the boiler and enclosed in a vertical

tube—the 'buoy pipe'—which protruded through the dome of the boiler

and carried within it a rod attached to the buoy. By means of this rod the buoy

controlled the opening of the injection cock in the following way. This cock

carried a shaped lever which became known as the 'F' because of its shape. With

the cock in the closed position, this F‑lever lay at an angle of about

30°to the horizontal, with its foot nearest to the plug rod and the letter

inclining upwards therefrom with the two short arms pointing downwards. The

shorter of these two arms was pierced with the square hole fitting over the

spindle of the injection cock, while the longer carried a weight at its

extremity. A short prolongation of the lever beyond the junction of this upper

arm engaged with a pivoted catch or detent lever known as the 'scoggan'. This

detent retained the lever in its closed position against the reaction of the weighted

arm which would otherwise fall and cause the injection cock to open.

Towards

the end of the engine's power stroke a peg on the descending plug rod depressed

the foot of the F‑lever until it reached the closed position where it was

retained by the detent. It was at this point in the cycle that the buoy came

into play. The steam admission valve having opened and refilled the cylinder

with steam as the piston 'went out of the house', the buoy ensured that another

power stroke was not made until the boiler had recouped itself sufficiently to

cope with the next demand for steam which must follow the power stroke

immediately. When the dome of the boiler had again filled with steam, the

slight pressure so created was aufficient to cause the buoy to rise in its

pipe, whereupon the vertical rod attached to it raised the detent lever, thus

enabling the F lever to fall by the action of its weight and so open the

injection cock. It is important to note that in devising this ingenious cycle

of operations Newcomen took it for granted that the steam demand of the

cylinder would temporarily exhaust the boiler and so allow the buoy to fall.

For if the buoy did not fall it would prevent the detent lever from returning

to position in order to retain the F lever when the descending plug rod again

restored the latter to the closed position.

It

follows logically that so long as the engine was controlled by the buoy its

action would be extremely slow. Whereas the word 'engine' to us implies

continuous motion, on the first Newcomen’s each return of the pump rods would be followed by a

prolonged pause while the boiler regained the necessary strength to perpetuate

the cycle of operations. It seems clear, however, that. partly as a result of

this extremely slow action, Newcomen did achieve a high degree of vacuum in his

cylinder which enahled the engine to work a load as high as 9 lb'in2 on the

piston. This compensated to some extent for the very slow rate of pumping.

Notwithstanding

the fact that instead of positive evidence we have a fog of confusing and

contradictory statements; the subsequent development of the engine can be

deduced with the assurance that, although it is necessarily conjectural, it

cannot be far from the truth. One explanation of the legend of the ingenious

boy with the piece of string is that it arose as a result of a

misunderstanding of the fact that

the ‘buoy' used by Newcomen was

not of the two‑legged species. Although such a misunderstanding may have

added to the confusion, it seems far more probable that such a boy did exist

but that those who mentioned him did not understand what he was set to do or

what it was that he achieved with his piece of string.

It

is obvious that, as soon as a Newcomen engine was provided with a boiler of adequate

steam‑generating capacity, it became no longer necessary for the boiler

to govern the working rate. Moreover, the old control gear could no longer

operate because the buoy would keep the detent or scoggan permanently raised so

that there would be nothing to retain the injection cock in the closed position

during steam admission. When this first occurred there was only one way in

which the engine concerned could be kept at work. This was by putting the buoy

out of action by wedging its rod in the pipe and then lifting the detent by

hand each time the piston reached the top of its stroke. The engine would then

work at a much faster rate provided the boiler could continue to maintain the

steam supply. I~o perform this monotonous operation, a two‑legged boy was

pressed into service instead of Newcomen's similarly named device. Standing

close beside the rising and falling plug rod, it would not take this boy long

to realise that the plug rod could very easily be made to do his repetitive job

for him. A suitably positioned nail in the plug rod and a length of cord from

the nail to the detent lever were all that was necessary. How delighted he must

have been with his crude but effective improvisation as each time the plug rod

neared the top of its stroke the cord tautened, raised the cletent and so

allowed the injection cock to open !

John

O'Kelly tells us of the boy's invention:

At

the beginning, they only made 6 to 8 and 10 strokes per minute and it was as a

result of the invention of a youth who watched over the machine rhat they

managed 15 and 16 strokes in the same period of time. This boy was called

ilumphrey Potter, but this invention made the machine very complicated.

Young

Humphrey Potter was most probably the brother of Isaac and John who were the sons

of Stephen Potter, brother to Humprey, Sen, and clearly a family trio who had a

tremendous influence on the introduction and development of the engine.

Desaguliers

however gives a most muddled account of the affair as follows:

They

used to work with a buoy in the cylinder, enclosed in a pipe: which buoy rose

when the steam was strong, and opened the injection and made a stroke: thereby

they were only able from this imperfect mechanism to make six, or eight, or ten

strokes in a minute; till a boy named Humphry Potter, who attended the engine,

added what he called a scoggan ‑ a catch, that the beam (or lever) always

opened; and then it would go fifteen or sixteen strokes in a minute.

It

is evident from this that the worthy scientist totally failed to grasp both the

object and the working principle of Newcomen's buoy gear. He begins by placing

the buoy in the cylinder, then blames the 'imperfect mechanism' for the fact

that the engine worked so slowly and finally credits the boy Potter with the

introduction of the detent lever or scoggan; all this to the infinite

bemusement of subsequent writers.

A

good example of the way in which nonsense begets nonsense appeared long

afterwards in the Mechanic's Magazine and was quoted by Stuart. Accepting

Desaguliers's account, the writer announced that the word scoggan was derived

from a north Yorkshire verb 'to scog', meaning to skulk or idle and that it was

obviously applied to the detent lever because it enabled its youthful inventor

to idle instead of attending to his monotonous job. In fact the word is of

Cornish origin and was doubtless first applied to the detent lever by Newcomen

or his associates during the course of pre‑1712 experiments in Cornwall.

The term is still applied in Cornwall to the Cornish engine valve gear, but it

will soon become an archaism now that this ultimate development of the

non-rotative beam engine has become a museum piece like its predecessors.

It

should be emphasized at this point that in designing his sorely misunderstood

method of operating his injection cock. Newcomen was the first to adopt the

principle of opening the valve by the fall of a weight and closing it against

gravity, a principle which has proved as long‑lived as the word scoggan,

since it persisted through the Watt era down to the last Cornish engine to be

built.

The

acceleration of the engine from a mere six strokes a minute to twelve of

fifteen strokes by the use of a more efficient boiler and the substitution of

the 'Potter cord' for the buoy to regulate the opening of the injection valve

was not achieved without loss in another direction. The faster rate of working

allowed less time for the cylinder alternately to gain and lose its heat with

the result that the degree of vacuum achieved below the piston was reduced. The

mean effective pressure of 9-1/2 lb/in2 originally adopted by Newcomen was

reduced to 7 lb/in2 or in other words half atmospheric pressure, to counteract

this loss, but it was immediately found that the less heavily loaded engine

working at the faster rate pumped more water per hour than it did before. Nor

was any more fuel consumed in proportion to the work done because the more

efficient boiler wasted less of the heat generated by the furnace.

If

contemporary engravings are to be relied upon, it would appear that the

earliest Newcomen engines were soon fitted with a refined version of the

'Potter cord' but that the buoy gear was retained. Beighton (1717), Barney

(1719), and, most surprisingly, Triewald's engraving of the Dannemora engine

(1734) all show both. No doubt when the boiler was steaming badly and could no

longer sustain the rate of working imposed by the Potter cord, it was

disconnected so that the buoy could take control. Meanwhile, however, the

provision of more adequate boilers was accompanied by the rapid accumulation of

experience among the men concerned with the erection and management of the

engines with the effect that the time soon came when it was felt that the buoy

gear could be safely discarded. By far the most likely explanation of the claim

that it was Beighton who "invented' the self‑acting valve gear in

1718 is that it was he who first took this step by dispensing with both the

buoy gear and the Potter cord on the engine which he erected at Oxclose

Colliery, Washington Fell. This would also explain the statement that until

this time the engine had remained 'perplexed by catches and strings'.

Beighton

is also said to have been the first to fit a weighted safety valve, or 'puppet

clack' as it was called, on the boiler of this engine at the suggestion of

Desaguliers. It lifted at a pressure of 12 lblin2. This sounds logical since

the elimination of the buoy would make a safety valve the more necessary, but

the fact remains that a weight safety valve features in Beighton's engraving of 1717 along with the buoy and

the Potter cord.

Stuart's

engraving of what he calls 'Beighton's Hand‑gear' shows a very simple

method of working the injection cock by means of two toothed sectors engaging

in each other at rightangles, the driving sector being mounted on the

horizontal axis of a lever which was alternately moved up and down by two pegs

in the plug rod. One of the early engravings featuring a gear similar to this

is that showing the engine at Passy (1726) which illustrates the French account

of that engine. If this was Beighton's gear, it was soon discarded in favour of

a return to the weighted lever released by a detent. Desaguliers describes and

illustrates the toothed sector method of opening the injection cock, but also

illustrates the weighted lever and detent, which he says is 'more used, and I

think a great deal better; because it moves with a Jerk, which is the best way

to overcome Friction'. The method by which this lever turned the cock might

vary and, instead of the Potter cord, the detent was henceforth tripped by a

striker on the plug rod, but the principle of opening by falling weight became

firmly established. Experience has shown that the more rapidly and positively

the injection cock could be opened, the better the result and it was for this

reason that the simple gear credited to Beighton failed to supplant the

weighted lever and detent first developed by Newcomen.

It

must be emphasised that early pictures of Newcomen engines are not an

infallible guide to chronological development. Artists either failed to

understand the principle of the valve gear and drew it indistinctly or

inaccurately, or else they copied their predecessor's work. Thus the Sutton

Nicholls engraving of what purports to be the York Buildings engine (1725)

shows the buoy gear only, which is certainly incorrect, while it seems most

unlikely that the Dannemora engine would have had the buoy gear unless it was

that Triewald doubted the ability of his boiler to supply so large a cylinder.

Such vagaries become excusable when we realise that with the sole exception of

clock‑work, no other self‑acting mechanism existed in those days.

Besides

the alternative admission of steam and injection water to the cylinder,

provision had to be made for the exhaustion from the cylinder of the hot

condensate and of any air brought in by the steam. When steam was first

admitted, the hot water, which had accumulated in the cylinder bottom during

the previous stroke, was expelled down a pipe into a hot well. A leather non‑return

valve at the foot of this eduction pipe prevented the water being drawn back up

the pipe when a vacuum was created in the cylinder. In the earliest engines the

hot well was at ash‑pit level, but later it was located above the boiler

steam dome so that the hot water it contained could be fed by gravity into the

boiler. Beighton is said to have been responsible for this innovation. This

first form of feed water heating brought about a sign)ficant saving in fuel.

Apparently

Newcomen did not at first appreciate that a certain amount of air would be

carried into the cylinder with the steam and he was accordingly mystified by

the fact that his engine would gradually lose power until it finally stopped,

air having accumulated to such an extent that an effective vacuum could no

longer be created. When the cause of this malady, which became known to

enginemen as 'wind‑logging', was recognized, Newcomen cured it by fitting

a small outlet pipe to the lower part of the cylinder through which the

incoming steam could expel any air. Like the eduction pipe, and for the same

reason, it was fitted with a non‑return valve. Because of the noise it

made, this air outlet pipe became known as the sniffing valve, 'sniff' being

then the equivalent of our'sniff'. The pipe was led into a small tank of water

which Barney calls a 'sniffing bason'. There any steam which passed was

condensed while the air bubbled through it. The overflow from this tank, led

either to the hot well or directly to the boiler.

A

cistern, mounted a little below the axis of the beam in order to provide a

head, supplied the water for injection. It was replenished by a small pump

worked, like the plug rod which operated the valve gear, by a small auxilliary

arch‑head set closer to the axis of the beam than the main archheads

so that the stroke was reduced. In Beighton's engraving the arch‑head for

this pump is shown outside the house near the pump end of the beam. Barney's

engraving, on the other hand, shows the pump in the engine house and driven

from the end of the plug rod. The pumps used for this purpose were usually of

the type known as

'jack‑head'. They

were of the common lifting type, but the top of the working barrel was closed,

the bucket rod passing through a leather‑packed gland in the cover. As

the bucket ascended, the water above it was forced up a pipe which branched

from the top of the working barrel. If Barney's drawing is correct, however,

the Dudley Castle engine was fitted with a plunger force pump of the type

introduced by Morland. This pumped on the down-stroke and to cope with this the

plug rod is shown coupled to the beam by two opposed chains anchored to the

midpoint of the arch‑head. Such an arrangement cannot have worked satisfactorily

and a jack‑head pump driven by a second auxiliary arch‑head on the

pump end of the beam became the rule.

The

water seal on the top of the piston was replenished by a branch taken from the

injectionwater supply pipe. Barney's drawing omits this supply pipe and

shows both the water seal and injection pipes branching from the pump delivery

pipe which delivers into the top of the cistern, an arrangement that could not

work satisfactorily and makes the cistern a mere ornament. The top of the

cylinder was belled out to prevent the water on the top of the piston from

spilling over at the top of the stroke. On the first engines the surplus water

from the top of the cylinder was led from the bell‑mouth by an overflow

pipe directly back to the boiler. The temperature of this water was never very

high, however, and it was led to waste after this arrangement had been

abandoned in favour of drawing feed‑water from the hot well.

There

was no means of machining the brass cylinder internally: its bore had to be laboriously

fettled and smoothed by hand. The piston was usually of cast‑iron and,

according to Desaguliers, Newcomen first used as a seal a disc of leather above

the piston with its periphery upturned so that it became, in effect, a gigantic

cup washer. This leather very speedily wore away in such a manner that the

upturned portion broke away to leave only edge contact between the leather and

the cylinder wall. Desaguliers goes on to say that Newcomen was delighted to

find that this made an effective seal. The use of such seals is confirmed in

the description of the engraving by Sutton Nicholls of 1725. The arrangement

adopted and standardized on some of the early commercial engines was to cast

the piston with an annular flange on its upper side, the outside diameter of

this flange being three inches less than that of the piston head below which

fitted the cylinder as closely as the techniques of the day permitted. With the

piston in the cylinder, soft hemp packing was then coiled and rammed into the

space between the face of the flange and the cylinder wall and finally

segmental weights were added to hold this hemp packing tight and in place. The

function of the water seal was to make this packing effective by keeping the

hemp soft and pliable. It could not, as is sometimes supposed, seal a seriously

defective or irregular cylinder bore because in such circumstances so much

water would pass the piston that creation of a vacuum would be seriously

impaired or prevented by excessive condensation of steam on admission.

The

beam or 'Great Lever' consisted of either a single massive oak timber or of two

such timbers secured together. The timber arch‑heads were mortised into the ends of the beam and

securely braced above and below by timber diagonals. The upper‑portions

of the arch‑heads were additionally braced by a stout iron rod

passing right through the arch‑head and so anchoring the chain by which

piston and pump rods were suspended. In all early engines, the trunnions were

placed at the mid point of the beam so that the strokes of piston and pump

bucket were the same.

Some

latter‑day observers have wondered why, throughout the long history of

the beam pumping engine, the pump end of the beam and its attendant gear should

have been exposed to the elements outside the house. Newcomen rightly decided that the load on the

beam trunnion bearings was such that they must be supported by the main wall of

the engine house. It was called the lever wall and was more massively built. To

enclose the whole would thus have involved the construction of additional walls

and roofing which would have proved obstructive when it became necessary to

withdraw the pump rods from the mine shaft. Very often these early mine shafts

were used for access into the workings and for raising coal and minerals as

well as pumping, so it was clearly impractical to enclose the top of the shaft

with an engine house. Examples of totally enclosed engines with beam trunnion

bearings supported on massive columns or 'A' frames may be seen, particularly

in waterworks installations, but

in the case of the Cornish mine pumpingengine Newcomen's practice of using

wall support persisted right down to the early years of this century when the

last Cornish engines were built.

On

a non‑rotative beam engine the length of stroke is not positively

determined as it is by the crank of any type of rotative steam engine. When the

engine was started by the hand manipulation of the levers controlling the steam

and injection valves, the length of stroke it made depended on the skill of the

engineman. When the self‑acting gear took over control, the length of

stroke was still determined by his judgement because successful transition from

manual to automatic control depended on the correct placing of the pegs in the

plug rod which actuated the valve levers. It was therefore necessary to provide a

form of positive stop to prevent the piston coming out of the top of the

cylinder or, through mismanagement, knocking the bottom out of the cylinder on

its descent.

52 William Pryce in Mineralogia

Cornubiens~s, 1778, includes a drawing of a Fire Engine as used in Cornwall.

The drawing shows the use of a balance bob to counterweight the weight of the

long pump rods.

When first admitted to the cylinder, the

steam might exert a small power on the piston, but this diminished rapidly as

the piston ascended until, as it neared the top of the stroke, it was literally

drawing the steam out of the boiler. But when a new engine had been completed

it had to be most carefully balanced to prevent the great weight of the

descending pump rods drawing the piston up with a violence which would damage

both the engine and the pumps. Weights were added to the beam immediately

behind the piston arch‑head and to the piston itself until the beam was in

perfect equipoise. A weight equivalent to 1 Ib/in2, of piston area was then

removed from the piston to give the pump end of the beam the necessary

advantage. Naturally, if the mine was deepened and additional pump rods were

added the engine would have to be rebalanced. In calculating the correct

balance in favour of the pump end, account was taken of the resistance of the

pump bucket as it descended through the water in the pump barrel,

the passage of the water past the bucket being restricted by the orifice of the

nonreturn valve in the bucket. The danger here occurred if the level of

water in the mine sump was so reduced that the pump drew air instead of water.

In that event the resistance of the air below the bucket might be insufficient

to open the nonreturn valve when it began its descent. If this happened

the weight of the whole column of water above the bucket would drive it down

with great and damaging violence before compression of the air became

aufficient to take effect. To guard against this the engineman was provided

with a float‑operated indicator which recorded the depth of water in the

mine sump. Even so, some form of positive stop was essential to arrest the

descent of the pump bucket and this took the form of sprung timbers known as

'spring beams' which provided a limited cushioning effect before becoming a

positive stop. The pictures of the Dudley Castle and Dannemora engines show

such spring beams mounted on stout timber stages above the mine shaft. The

moving stop connecting with them consisted of a strong iron rod which passed

through the top of the archhead and projected on each side of it. This

became known as the 'sword'. The alternative, which soon superseded this

arrangement, was to mount the spring beams on a staging within the

upper part of the mine shaft, the sword being then carried by the first length

of pump rod. Presumably this arrangement was used in the engine portrayed by

Beighton since he shows no overhead spring beam staging on the outdoor end.

Inside

the engine house a precisely similar arrangement was used to prevent the piston

from damaging the cylinder bottom if it 'came into the house' too violently. In

this case the spring beam stagings were carried on two beams extending from

wall to wall of the house as shown by Barney and Beighton. The artist of the

Dannemora engine has omitted them in error because the supporting beams are

shown. Below these supporting beams two even more massive timbers bridged the

engine house in order to carry the cylinder, the latter having a cast flange

which rested upon them.

Most

early pictures of Newcomen engines show single forged‑link chains

coupling piston and pump rods to the arch‑heads. These were soon

discarded in favour of pin‑jointed chains with flat plate links which

were easier to repair or renew, lay more snugly on the arch‑heads and

were more readily coupled to cross‑heads when two or more sets of pump

rods were used. Duplex or multiple chains took the place of single chains on

both arch‑heads as mines deepened and engines increased in power.

54 The use of quadrants and horizontal

connecting rods is shown in this drawing of 'The Slide Engine at Mill Close

1756', one of the London Lead Company's lead mines in Derbyshire. This is an

early example of the use of flat rods, widely used in Cornwall in the next

century, to pump from a shaft some distance from the engine [Image Deleted]

Little

has been said so far about the arrangement and construction of the pumps in the

mine. It seems most unlikely that Newcomen was responsible for any notable

innovation in this department, but his engine, by bringing much more power to

bear, necessitated the rapid development of techniques which were first applied

in mines a little earlier. The first mechanical means of raising water from

mines consisted of chain‑and‑bucket pumps powered by waterwheels,

or by horse gins in situations where water power could not be harnessed. Rodoperated

lifting pumps began to supersede bucket pumps in the first decade of the

eighteenth century, such pumps being driven by crank from a waterwheel. George

Sorocold, an English engineer noted for his water‑powered water supply

installations, is said to have been responsible for introducing lifting pumps

to the Scottish collieries in 1710 and their use soon spread to Tyneside

through the agency of the Earl of Mar who owned property in both districts. It

seems probable, too, that lifting pumps were beginning to supersede chains and

buckets in Cornwall at the time when Newcomen was making his first experiments

there.

While

the means available were so inadequate, miners were prepared to go to immense

pains to avoid the necessity of pumping. Adit tunnels were driven to carry the

water away to low ground and in some districts, notably in Derbyshire, these

tunnels were often of great length. The introduction of Newcomen's engine

enabled mines to be worked below the level of these edits, but they were still

used since it was obviously uneconomic to raise water farther than was

absolutely necessary. If the edit level was far below the top of the mine

shaft, it meant that the pump end of the engine beam had to carry a great

length and weight of dry rods, or 'dry spears' as they were called, which

necessitated the use of very heavy counterweights. To avoid loading the beam to

such an extent, the practice of using an auxilliary beam or 'balance bob' which

was mounted at the mouth of the shaft or as a separate beam above the engine

main beam, was initiated. One end of this beam was coupled to the pump rod,

while the other end carried a box filled with blocks of stone or scrap metal to

serve as a counterweight to the rods. This not only relieved the load on the

beam but greatly simplified the task of rebalancing when alterations in the

mine made this necessary.

In

order to save weight the pump rods or 'spears' were of fir or mast timber in

lengths of from 40 to 60ft, the joints between them being scarfed and held

together by crossbolts and fishplates. In the case of the 'wet spears' that

passed down the pipe through which the water was drawn, the buoyancy of the

wood in the water relieved the weight on the engine. To provid access to the

mine there was a series of timber stages interconnected by ladders in the mine

shaft and on each of these stages the pump rods were guided by rollers to

prevent them from bowing as they descended.

Forty‑five

yards was considered the maximum lift for a single pump and in practice the

single lift was usually substantially less than this. In deep mines this

necessitated a series of pumps placed at different stages down the shaft, each

drawing from a wooden cistern filled by the pump next below. Such pumps would

be driven by rods of smaller section coupled by crossheads to the main rod.

Such a series of pumps would be identical except that the lowest, which drew

from the mine sump, would have a different suction pipe or 'wind bore'.

As

we know from the Edmonstone and Whitehaven engine accounts, the earliest pipes

through which the water was lifted were of elm banded with iron, but these wooden

pipes were soon superseded by iron pipes with flange joints. The lowest length

of pipe next to the working barrel of the pump was of slightly larger diameter

than the rest and was provided with an access door. Into this pipe the bucket

of the pump could be drawn when it, or the valve within it, required repair or

replacement and on this account it was called the 'bucket piece'. Below this,

the working barrel of the pump was generally of brass or bell metal to resist

corrosion and would be 9ft long if the working stroke was 7ft. Immediately

below the pump barrel was a length of pipe

called the 'clack piece'. Its expanded upper end formed a conical seating for

the clack or foot valve, an access door being provided similar to that in the

bucket piece. The foot valve was fitted with an iron loop which could be

grappled from above after the pump bucket had been withdrawn in case it

required attention when the mine was flooded above the level of the access

door. Finally, below the clack piece was the suction pipe or wind‑bore,

the combined lengths of these two sections being so determined that the suction

lift did not exceed 25ft when the pump bucket was at the top of its stroke.

Unlike

those fitted to the intermediate pumps, the lower end of the wind‑bore in

the mine sump was deliberately constricted to produce a powerful suction and so

reduce the inequality of load in the eventuality of air being drawn in. It

terminated in an elongated bulb pierced with holes and the suction could be

varied according to need, either by stopping some of the holes with wooden

plugs or by adjusting a sleeve of leather over the bulb. The sound produced by

a large beam pump as it drew through these holes was tremendous. To miners who

depended for their livelihood on the reliability of the pumps it may have been

a familiar and reassuring noise, but to the uninitiated it was awe‑inspiring

to hear, reverberating through the cavernous darkness of the mine galleries, a

sound like the stentorian breathing of some sleeping giant. It was because of

this characteristic sound that these holes were aptly named 'snore holes'. In

deep mines the lowest pump was generally given a short lift. Th1s was an

additional precaution because it minimized the reduction in load which would

result if the pump drew air.

The

only purpose other than mine pumping to which Newcomen's engine was applied

during the inventor's lifetime was that of supplying water to towns, the

engines at Passy, near Paris, and York Buildings being the first examples.

Here, instead of being lifted from a great depth, the water had to be forced

upwards and this necessitated a totally different arrangement of pumps. Two

pumps were installed side by side, the one a jack‑head lifting pump of

the type used to raise water to the injection water cistern and the other a

plunger forcing pump as patented by Sir Samuel Morland and first produced

commercially in Great Russell Street, London, by Isaac Thompson. The crosshead

linking the two pump rods to the arch‑head chains was guided by grooves

cut into two upright timbers. The jackhead pump rod was of round section

iron, turned and polished where it passed through the leather pump gland. The

middle portion of the force pump rod consisted of two wooden planks holding

between them weights of lead or pig‑iron. The engine raised the jack‑head

pump bucket on its power stroke, while the descending weights actuated the

force pump and returned the engine piston to the top of the cylinder. The

delivery pipes from the two pumps were led into a closed cistern or receiver in

which the compression of air acted as a balancer, forcing the water in a steady

stream up a rising main to a storage reservoir placed at a sufficient height to

provide enough head for the town supply pipes. According to Triewald the York Buildings

engine pumped to a reservoir containing 'several thousand hogsheads' from which

water was conducted through lead pipes to every floor of 'over 500 many‑storied

houses' in the vicinity of Hanover Square, now Hanover Place off Long Acre. On

each floor, he tells us, two taps were provided, one for domestic use and the

other a'fire tap' with a threaded outlet to which a leather hose could be

attached. Such a precaution reminds us that the great fire of London was then

still recent history.

So

concerned was Triewald to 'sell' the new power to his countrymen in Sweden that

he made claims for Newcomen's engine the extravagance of which would have

shocked the inventor. His most gross exaggeration reads as follows:

As

to the durability of this machine it certainly possesses no small advantage

over other art)fices; because the noblest part of the machine are made of

metal, copper, lead or iron and ought thus, as a matter of course, to be able

to defy time, nay, a cylinder, after a hundred and even a thousand years' use,

is better, and never can be worse.

So

far was this from the truth that some engine cylinders required renewal within

Newcomen's lifetime. This might not be due solely to bore wear but to casting

defects disclosed either by wear or by the 'working' of the cylinder on its

wooden bearers when under load. Of the twenty‑three number and size, from

three mines with 47in engines in 1746, to a 70in engine at Herland Mine in

1753. Borlase, writing in 1758 remarks upon the number and size of the engines then

at work and refers to engines at North Downs mine, Redruth (2), Pit Louran,

Redruth (2), Polgooth, Wheal Reeth, Bullen‑garden, Dolcoath, the Pool,

Bosproual and Wheal Rose. In 1769 when the north country list was compiled,

John Smeaton collected particulars of eighteen large engines then at work in

Cornwall, eight of them having cylinders exceeding 60in diameter. Nine years

later it was stated by Pryce in his Mineralogia Cornubiensis, that more than

sixty engines had been built in Cornwall since the coal duty was remitted in

1741 (although at least another ten engines built between these dates can be

accounted for now) and that many of these had subsequently been rebuilt and

enlarged.

The

most notable Cornish engine builders at this time were Jonathan Hornblower (son

of Joseph, Newcomen's associate), John Nancarrow (who had provided Borlace's

list of engines) and John Budge. The engines built in Cornwall were of a higher

standard than those in the north of England, for fuel economy was all‑important

and provided a great incentive for engine builders to strive for greater

efficiency. Moreover, Jonathan Hornblower disseminated a wealth of experience

which he had inherited from his father.

It

is appropriate that it should have been Josiah, a younger brother of Jonathan

Hornblower, who was responsible for introducing the Newcomen engine to the New

World. This historic engine was ordered in 1748 or 1749 by Colonel John

Schuyler who, with his two brothers, owned a copper mine in what is now North

Arlington, New Jersey. Copper had been found on the Schuyler estate in 1715 and

was profitably worked by driftways until 1735 when it became necessary to sink

a shaft. The ore was exported to the Bristol Copper and Brass Works where it

fetched 40 a ton. When the shaft reached a depth at which the water could no

longer be cleared by horse power, John Schuyler made the inquiries in London

which led to his order.

Josiah

Hornblower was chosen, perhaps by his better known elder brother, to erect the

engine and on 8 May 1753 he set sail from Falmouth on a coasting ship bound for

London where the engine parts, many in duplicate and some in triplicate, had

been gathered ready for shipment.

With

the engine and its erector on board, the American ship Irene sailed from London

on 6 June 1753 and encountered such rough weather and adverse winds in the

North Atlantic that she did not reach New York until 9 September. The rigours

and perils of the crossing were such that Hornblower swore he would never make

an ocean voyage again. Much to the sorrow of his family in Cornwall he kept his

vow and never returned.

At

New York the engine was trans-shipped to a smaller craft which carried it

through Newark Bay and up the Passaic River to an unloading point at Belleville

opposite the mouth of the Second River. It was then carted overland for about a

mile to the head of the mine shaft which was located near the junction of

Belleville and Schuyler Avenues in North Arlington. So arrived the first steam

engine in the American continent, an event less celebrated than the landing of

the Pilgrim Fathers but no less pregnant with sign)ficance for the future.

All

the engine parts were on site by the end of September 1753, but erection was a

slow and laborious job for Hornblower. Stone for the engine house had to be

quarried from the mountains and trees felled for the engine beam and other

timber work. The accounts show that no less than 211 days were spent in carting

stone, timber and clay for bricks to the site, and it was not until March 1755

that the engine was set to work. The engine appears to have worked well and was

twice rebuilt following damage by two successive fires before the mine was

finally abandoned in the early years of the nineteenth century. It would appear

that at each rebuilding a new cylinder was fitted, the first two being of brass

and the last of iron. The diameter of the brass cylinder is not stated, but on

the 1889 evidence of Mr Justice Bradley of Washington, who married a grand‑daughter

of Hornblower, the last cylinder 'was of cast‑iron, an inch or more in

thickness, nearly eight feet long

and more than two and one‑half feet in diameter'. A relic preserved in

the Smithsonian Institution, the United States National Museum at Washington,

is believed to be the lower half of this cylinder. The engine is said to have

pumped at the rate of 134 gallons per minute from a depth of 100ft using a 10-in diameter pump barrel, an iron

lifting pipe in 8ft sections and wooden spears.

Josiah

Hornblower married and settled in the district where he was associated with the

mine until 1794. In that year he built for the last owners of the mine, Messrs

Roosevelt, Mark and Schuyler, on land which he sold to them on the outskirts of

Belleville, the first ore stamping mill in America. Here, too, the mine owners

established a foundry and machine shop where the first steam engine to be

manufactured in America was made. This works was named Soho after its famous

counterpart in England, but the historical link is not with Boulton and Watt

but with Thomas Newcomen through Josiah Hornblower and his father, Joseph.

Josiah Hornblower died at Belleville on 21 January 1809 in his eightieth year.

According to C. W. Pursell's Early Stationary Steam Engines in America the only

other atmospheric engines built in America were at a Philadelphia distillery in

1773 (which was never completed), at New York Waterworks about 1774-6 and at an

iron mine in Rhode Island about 1776.

Another

Cornish engineer who emigrated to America was John Nancarrow, one of the most

notable engine erectors of his day. Although still in Cornwall in 1757, by 1786

he was operating a steel furnace in Philadelphia when he was consulted about

building an engine for a steamboat.

James

Brindley was associated with the Newcomen engine in the mid‑eighteenth

century. In 1756 he erected a 36in engine for Thomas Broade at Fenton Vivian in

Staffordshire. According to details of this engine which Carlisle Spedding sent

to his friend William Brown, Brindley mounted his cylinder in the wall of the

engine house opposite the lever wall. It would seem that Brindley did this, not

because he was aiming at a more rigid structure, but because his patent boiler

could not be conveniently accommodated within the engine house. This boiler

consisted of a brick vault 18ft long with a floor of cast‑iron plates

over four small furnaces. Each furnace had its own iron flue pipe which passed

back through the water in the boiler before entering the chimney. The parts for

the engine were supplied by the Coalbrookdale Company, and their accounts show

that Brindley was still experimenting with his boiler in 1759. It was not a

success. Although Brindley erected a number of engines in North Staffordshire

and elsewhere he was relatively little involved in steam power. Compared to the

many other engine builders, such as Wise, Nancarrow, Hornblower, Budge, Curr,

Brown, Smeaton, Thompson and other who are even less well‑known today,

Brindley's contribution was very small indeed, and he is best remembered as a

canal engineer.

Return

to the Newcomen Engine Index

About

The Hopkin Thomas Project

Rev.

March 2010