THE NON ROTATIVE

BEAM ENGINE

A monograph concerning the history of,

and technical information on,

the NEWCOMEN, the BOULTON & WATT

and the CORNISH engines

by

MAURICE KELLY

Member of the Newcomen Society.

Formerly: 2nd Engineer Officer, Royal Research

Service & British Merchant Navy.

Chief Engineer Officer, Marina Mercante de

Republica de Panama.

Previous Works by the Author:

"The Overtype Steam Road Waggon"

Goose & Son Publishers, Norwich. 1971.

"The Undertype Steam Road Waggon"

Goose & Son Publishers, Cambridge. 1975

"The American Steam Traction Engine"

CMS Publishing, Stamford. 1995

@ MAURICE KELLY 2002

All rights reserved. No part of this publication may

be reproduced, stored in a retrieval system, or transmitted in any

form or by any means, electronic, mechanical,

photocopying, recording or otherwise without prior permission in

writing from the publishers.

Maurice Kelly asserts the moral right as the Author of

this Work.

British Library Cataloguing‑in‑Pubhcation‑Data:

a catalogue record of this book is held by the British Library.

First Printing 2002 ISBN No. 0‑9536523‑3‑5

Published in Great Britain by:

CAMDEN MINIATURE STEAM SERVICES

Barrow Farm, Rode, Frome, Somerset. BA11 6PS

Camden stock one of the widest selections of

engineering, technical and transportation books to be found;

Write to the above address for a copy of their latest

free Booklist.

Layout

and Design by Camden Studios and Andrew Luckhurst, Trowbridge, Wilts. Printed

and Bound by Salisbury Printing Co. Ltd.

CHAPTER 3: THE BOULTON & WATT ENGINE

During

the first half of the 18th Century with only SAVERY, NEWCOMEN and

the "Proprietors" operating in the field, there did not seem to be a

need for the extensive patenting of ideas relating to the 'Fire Engine'; so much

so, that THOMAS NEWCOMEN decided to develop his

engine under the protection of the SAVERY umbrella rather than attempting

circumvention. However, although the SAVERY Patent appeared to be all embracing

at the time there must have been Ôa chink in the armour' for one MARTEN

TRIEWALD, who also erected the first NEWCOMEN engine in Sweden

at Dannemora Mine in 1727, had previously applied for, and had been granted, Letters

Patent at the British Patent Office in 1722.The specification of this patent,

(Brit.Pat. No 449 of the 29th June 1722), was entitled as a "Machine for

Drawing Water out of Mines&Collieries

by the Power of the Atmosphere". This could only have been a description

of a NEWCOMEN style of engine and it is interesting to consider how it managed

to avoid clashing with the SAVERY invention. Nevertheless, whilst "The

Proprietors" managed to reap a good harvest there appears to be no record

of TRIEWALD extracting royalties for his specification.

In

the second half of the 18th Century patents came very quickly as inventors

sought recognition of their ideas. Many well‑known names applied for

protection during this period and the most famous of these was JAMES WATT who

was granted his groundbreaking patent for the 'Separate Condenser' on the 5th

January 1769, (Brit. Pat. No. 913 of 1769). The protection afforded by this

patent enabled WATT in collaboration with MATTHEW

BOULTON, who was a financier and manufacturer, to exert a very

tight rein on the whole of the steam engine industry until 1800. It is on

record that JAMES WATT was extremely jealous for the

reputation of both his patent and of his firm, for he was very quick to

threaten litigation if he thought infringement was imminent. The validity of

the WATT patent was only tested in court right at the end of the Century with

the celebrated cases of BOULTON

¥

WATT v. BULL & BOULTON and BOULTON

¥

WATT v. HORNBLOWER & MABERLEY in

the Court of Common Pleas in 1799.

JAMES

WATT did not 'invent the steam engine' as popular

historians would have it; he was a very shrewd improver who sought to gain

efficiency in a prime mover that had had fifty years of limited success. WATT's

inventions made the NEWCOMEN engine into a basically useful machine that would

be capable of being developed into the ancestral unit of all of today's

reciprocating engines. The story began, as legend has it, with WATT beginning

his studies into steam and its properties in 1759. From the outset JAMES WATT

approached his work scientifically and this was the basis for his success. He

investigated the laws of temperature and of pressure in elastic fluids, the

nature of the expansion of steam and the role of fuel in the evaporation of

water. The turning point of his work came in 1763 when he was requested to

repair a small model of a NEWCOMEN engine which was the property of the

University of Glasgow; in attempting to set this machine to work he noted a

number of deficiencies to be present and he made experiments in order to remedy

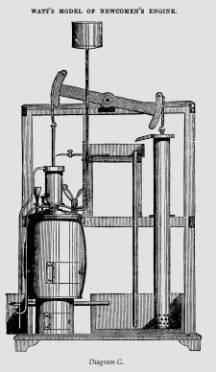

them. A line drawing of this engine is shown in Diagram 'G'; the model is

preserved by the University of Glasgow being on show to the General Public at

the HUNTERIAN MUSEUM.

From

his experimental work in science and his practical application with the

NEWCOMEN model, WATT was able to formulate the specification contained in his

patent of 1769. This described the operation of a separate condenser which revolutionized

the efficiency of prime movers driven by steam.

Amongst

his remedies to improve efficiency WATT made the following observations: ‑

a) That the cylinder be maintained as hot as possible and to this end he

encased it with a steam jacket.

b) That the steam be condensed in a vessel remote from the cylinder.

c) Removal of air from the system.

d) Use of the expansive force of steam in the cylinder.

e) The use of oil, grease or even mercury to seal working parts instead

of water.

Applying

these principles WATT built a model of a single‑acting engine as part of

the 1769 Patent and this model is also preserved in the KELVINGROVE MUSEUM

& ART GALLERY in Glasgow; from all of this work a single‑acting, non‑rotative

beam pumping engine was derived, and an illustration of this machine is shown

in Diagram 'F'. Whilst the engine has much in common with the NEWCOMEN type,

the drawing shows the important differences which revolutionized the state of

the art in the 18th Century. To work the engine it was necessary to blow

through the steam, equilibrium and exhaust valves with steam to expel all of

the air from the cylinder, condenser and steam piping etc. After this the

equilibrium valve was shut and the injection cock was opened to create a vacuum

beneath the piston and allow steam pressure to force the piston downwards. By

closing the steam and exhaust valves and opening the equilibrium valve the

steam forcing the piston down was allowed to go to the underside of the piston

to cause it to be in equilibrium. At this point the weight of the pump rods

pulled the piston to the top of the cylinder. From this stage automatic working

could be maintained by the tappet rods and associated valve gear once the

manual starting regime had been effective. In Diagram V all of the main

components of the BOULTON & WATT engine are illustrated; in particular

those items introduced by WATT may also be seen, as follows:

a) The Steam jacket to keep the cylinder warm.

b) The Separate Condenser which precluded cold water in the cylinder.

c) The Air Pump to draw off air and condenser water effectively.

d) The Piston, Cylinder Cover, Glands and Stuffing Boxes all properly

sealed.

These

together with the Cataract Governor, and the expansive working of the steam

inside the cylinder enabled WATT to so improve the efficiency of the engine

that it used but one‑third of the fuel consumed by an equivalent

atmospheric engine doing the same work.

This

economy in the use of fuel was soon recognized by the mine owners, particularly

in Cornwall, and the BOULTON & WATT units were very quickly adopted

throughout the country. When BOULTON & WATT granted licenses to erect their

engines according to the 1769 Patent, the firm received a third part in value

of any saving in fuel for each engine made to their specifications up to 1800.

These royalties soon made JAMES WATT and his partner MATTHEW

BOULTON very wealthy in a short space of time.

Another

important component of the WATT system was the fitting of the Cataract Governor

which was a simple method of regulation for the single‑acting engine.

This device operated in the following way: it consisted of a pump that was

placed within a tank of water that was situated well below the bottom of the

cylinder. The Plunger of this pump was attached to a long lever which was

loaded with a heavy weight on the same side as the fulcrum of the plunger, with

this lever projecting out from the other side. The tappet rod, (seen more

clearly in Diagram F), engaged with the lever when the piston travelled

downwards and so raised the plunger of the pump. When the piston ascended

again, the weight on the end of the cataract lever caused the plunger to

descend and so force out the water that it had drawn in during the upward

stroke.

This

water was forced up through a small cock and the time occupied by the pump

plunger descending depended upon the variation in the opening aperture of the

cock. From this system the engineman could control the regulation easily by

opening or closing the cock to vary the number of strokes. Presumably if the

cock was shut completely the water was pumped out via a by‑pass pump.

As

has been mentioned before in this text, there was a rash of patents concerning

the 'fire‑engine' in the latter half of the 18th Century and one that did

cause JAMES WATT to think carefully was of a specification for a

modified SAVERY engine filed by WILLIAM BLAKEY and

granted Letters Patent in 1766 Ð this referred tp oil on the surface of the

water to read do reduce condensation. (Brit. Pat. No. 848 of the 10th June 1766

‑ "Machines worked by Fire & Water with Reduced Friction

Thereof"). As a result of this patent WATT specifically

excluded all SAVERY type engines from his specifications as they did not have pistons.

Another very important legal move that was made following the granting of the

1769 Patent was the 1775 Steam Engine Act. (Anno Regni Decirno Quinto Georgii

III Regis). This was an Act of Parliament which vested in JAMES WATT, Engineer,

and his Executors, Administrators and Assignees, the sole use of steam engines

of his invention throughout the United Kingdom and His Majesty's Dominions for

a limited length of time. The Patent and the Act made WATT invincible

in the realms of steam engineering at that time and gave him such an overall

monopoly that it would have seemed foolish to challenge it. But challenge it

they did, for in 1781 JONATHON HORNBLOWER was granted Letters

Patent for a system of compounding which is depicted in Diagram 'J'. (Brit.

Pat. No. 1298 of 1781). This patent precluded WATT from using the expansion of

steam in a second cylinder of greater diameter than the first.Another patent,

which was granted to a mill owner named PICKARD in

1780 to cover the crank infuriated WATT, as he claimed the

invention as his own but was stopped from using it! (This, of course, referred

to rotative engines and is, therefore, outside the scope of this work).

Diagram H.

JAMES

WATT himself went on to patent other features of the steam

engine, however, and these were as follows:

Brit.

Pat. No. 1321 of the 12th March 1782 ‑ Expansive use of Steam, Double‑Acting

Engines and Compounding, Rotative Engines etc.

Brit.

Pat. No. 1432 of the 28th April 1784 ‑ Various mechanisms including the

Parallel Motion, the Balance of Pumg Rods, Steam Hammers, General Application

of Steam Power in Mills etc., and the Application of Steam power to Carriages

etc. (to which he was violently opposed!).

Brit.

Pat. No. 1481 of the 14th June 1785 was a pertinent one in the present day, for

WATT recognized the effect of pollution in the atmosphere

and sought to remedy it as much as he could, forthe specification calls for the

introduction of "Smokeless Furnaces & Fire‑places" to

combat the evil. In a Patent of 1781 WATT had to resort to

the 'Sun & Planet Motion' to circumvent PICKARD and

in the 1782 Patent he resorted to equal diameter cylinders to effect

compounding which was nowhere near as effective as the idea of HORNBLOWER.

The

impact of JAMES WATT upon the whole of the industrial

scene in the 18th Century was to revolutionize the ways in which people worked,

with a move from the countryside to the city, and it paved the way towards

complete mechanization which developed between the 19th and the 20th Centuries.

His association with MATTHEW BOULTON in 1773 had important

repercussions in the industry, no least of which was the setting up of the

"SOHO MANUFACTORY" in Birmingham in 1774 which was the first purpose‑built

engine building establishment to appear. The word 'factory' came into the

English language from this title. WATT always insisted

on using the best materials available and having the best workmanship from the

start; by the end of the 18th Century the elegant BOULTON & WATT engines

with their cast‑iron beams, parallel motion, precision valve gear and

excellent polished finish and paintwork were far removed from the crude

machines of the earlier part of the century.

The

BOULTON & WATT Engine was adopted by many differing undertakings very soon

after its fuel savings were recognized. Workshops of varying kinds, mines,

waterworks and latterly iron‑founders (for blast furnace blowing)

invested in them and the firm became a byword for excellence. One of the first

areas that JAMES WATT set out to conquer was Cornwall; marketing

of the engine was done aggressively and WATT and

his associates spent a considerable amount of time supervising work in the

county. This tended to divert their attentions from other markets in the first

instance, but as the success of the machine was broadcast other fields became

open to the Partners. It must be stressed that great success was achieved in

Cornwall, for between 1777 and 1801 some 52 engines were erected, of which at

least two were of the rotative variety. In this period of time the NEWCOMEN

Engine was effectively displaced, for by 1783 there was only one such unit in

the county, and this was out of use. During the time that BOULTON & WATT

were operating in Cornwall they netted a total of 180,000 pounds in royalty

payments for their work. This was done by insisting that all of the work,

including that of alterations to existing engines, was to be done by the firm,

their workmen or their licensees. This sum represents 88 million pounds in today's purchasing power.

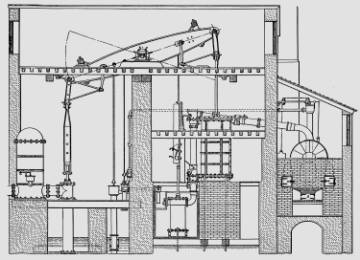

Fig. 9 ‑

The Boulton & Watt engine erected at the Chelsea Waterworks in Pimlico,

London in 1803.

Eventually

BOULTON & WATT turned their attentions to London where the price of coal

was very expensive and where concerns such as waterworks could make great

savings if the WATT system was adopted. The first engine

to be supplied by the partners was to a distillery in Bow. It was erected there

in 1776, this being personally overseen by WATT himself.

WATT also, at that time, took the opportunity of testing

various atmospheric engines in the capital to determine their average coal

consumption, and to compare the results with the performance of one of his

engines. Unfortunately, the progress towards the adoption of the BOULTON &

WATT engine in London was not particularly swift as the water companies there

were not keen on capital expenditure, despite the fact that great savings might

be made in fuel costs. It was not until 1778 that a 27 ins. dia. engine having

a stroke of 8 ft. was installed for waterworks use at Shadwell. In the same

year another engine was erected at Chelsea and this one had a cylinder diameter

of 30 ins. also by 8 ft. stroke; this engine seemed to have been of an

experimental nature as it was set up for expansive working according to the

provisions of the 1782 Patent and must, therefore have been the pilot exercise

for that specification. WATT claimed the duty of 32 Millions for this engine

which was very optimistic and possibly exaggerated. He ceased the use of

expansive working soon after the inception of this engine. Other modifications

were made to the unit including altering it to rotative working but this proved

to give it an uncomfortable, jerky motion and it soon reverted to being non‑rotative.

Also it was subject to a bad accident when the pump end chain broke and the

piston came in‑house with such force as to break the cylinder bottom, and

crack the cylinder wall. A new cylinder bottom was cast locally and WATT

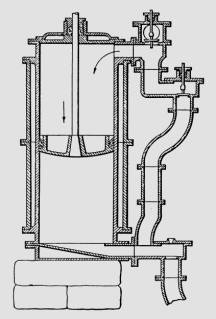

managed to close up the crack in the wall. Diagram 'K' shows a section through

the cylinder of this engine together with the disposition of the valves and

piping. Several other BOULTON & WATT machines were supplied to London

waterworks but one of the most celebrated was the single‑acting engine

that was built in 1803 for the Pimlico Wharf Pumping Station of the Chelsea

Waterworks. This engine had a cylinder of 48 ins. diameter by 8 ft. stroke to

draw water from a depth of 126 feet by means of a 17-1/2 ins. diameter pump. It

made between 13-1/2 to 14 strokes per minute and it was capable of delivering

175 cu.ft. of water into the reservoir at each stroke; its rated horsepower was

43.2. The line drawing shown in Fig. 9 depicts the engine which was the pitome

of BOULTON & WATT design and production during the lifetime of JAMES

WATT himself. It worked successfully for a period of thirty‑five

years.

Diagram

K.

At

the end of the 18th Century WATT began to perfect the

double‑acting principle for his engines, whereby the steam pressure acted

on both sides of the piston, and a number of non‑rotative pumping engines

were manufactured to this design. One of the most interesting was an inverted

unit, somewhat similar to a BULL engine, that was erected in 1795 at the

Hallenbeagle Mine in Cornwall. The inverted cylinder, which measured 52 ins.

diameter, drove directly down the shaft where it was connected to rods either

side which operated two sets of pit‑work. A small beam driven from a tail

rod. and situated overhead. worked the air pump which was placed outside the

engine‑house. The original design for this engine was believed to have

been drawn up by WILLIAM MURDOCH, WATT's assistant, and WATT

himself made a drawing of it which was dated the 16th

July 1795. It appears that JAMES WATT first considered

the double‑acting principle in 1774/5 when he produced a drawing to be

shown to the Committee of the House of Commons; this drawing depicted a

cylinder and a condenser working on that principle. The original double-acting

engines made by BOULTON & WATT were rotative units but a non‑rotative

experimental engine was set to work in the Soho works in 1783. This engine had

a cylinder of 18 ins. diameter by 18 ins. stroke; it worked a rack and pinion

system but it operated with such force that it broke the rack gear repeatedly.

The first double‑acting pumping engine was erected at Wheal Towan in

Cornwall in 1785, being a small unit operating on the rack system as in the

Soho machine. Another small engine using a different method of connection, viz.

a roller and guide mechanism, was erected at Wheal Crane at more or less the

same time. However, double‑acting BOULTON & WATT engines followed

quickly with engines being erected at Wheal Messa (42 ins. dia) with the air‑pumps

etc. in house, Wheal Fortune, a 45 ins. dia. engine with condensing vessel and

parallel motion and the great 63 ins. Wheal Maid engine which was said to have

been the most powerful prime mover in the world at the time. Another 63 ins.

engine was also installed in 1798 at the Hebburn Colliery in the Durham

coalfield and this reached the peak of non‑rotative engine design

achieved by the BOULTON & WATT firm. Despite all of these engines working

on a new and, in 1783 untried design, they were all eminently successful and

the double‑acting principle went on to be the standard form of steam

reciprocating engine down to the present day.

Notwithstanding

the success of the double‑acting type of engine, the single‑acting

engine continued to find favour with the mine engineers, and non-rotative

single‑acting machines were built into the 19th Century when the Cornish

cycle was perfected.

After

the expiry of WATT's patent in 1800 it seems that BOULTON

& WATT concentrated on the rotative engine, for the company made a far

greater number of those than of the up‑and‑down pumping engines;

altogether the firm constructed a total of 496 engines between 1775 and 1800

when the patent expired. Of these 164 were pumping engines, 24 were blowing

engines for blast furnaces and 308 for driving machinery, the latter are almost

certain to have been rotative.