Excerpts

from

NEATH

AND

DISTRICT

A

SYMPOSIUM

Edited

by Elis Jenkins

PUBLISHED

BY ELIS JENKINS

NEATH

1974

Chapter

8

IRON

INDUSTRY

by

D. Morgan Rees

THERE are detailed references to

early furnaces and forges in a well-known work1 on Neath and its neighbourhood. This detail is

valuable because, in the main, it is based on documentary evidence. It is,

however, in one sense a bewildering catalogue of information, which needs to be

sifted for the purposes of this chapter.

There is evidence to support the

existence of a forge in Cadoxton in 1566 and also of forges in Briton Ferry and

Glyndulais during the 1660s and 1670s. The first mention of an ironmaking

furnace is obtained from the lease in 1694 of 'a parcel of land whereon an iron‑melting

furnace stood' at Cwm Felin.

D. Rhys Phillips makes a number of

references to a furnace at Melin-y-cwrt,' providing many interesting and useful

pieces of information, particularly about the origin of the supply of iron ore

to the furnace. Some of it came from Banwen Pyrddin, beyond Onllwyn at the head

of Afon Dulais, carried by pack‑horses and 'it was also obtained from

Cwmgwrach'. This is an interesting observation in view of the building of a

blast furnace during the nineteenth century in this area.3 Phillips is quick to correct hasty conclusions reached by

the local historian Carw Coch (William Willisme), that the furnace at Melin‑y-cwrt

was first operating in 1736, by calling on documentary evidence which proved

that charcoal and iron ore were being carried to the furnace in 1718.4 An interesting item in this

reference is to the payment made to a 'collier', the name given to the man who

burned timber into charcoal, and his assistant. The charcoal suppliers often worked

independently of the furnace proprietors at this time.

It is possible to provide an earlier

date for the Melin-y-cwrt blast furnace. The reference was discovered by Dr. H.

R. Schubert,5 who will

always be among the foremost historians of the Iron and Steel Industry in

Britain, in a manuscript which was at the time in the Pontypool Public Library.

It is as important as any manuscript relating to the making of iron in South

Wales during the early years of the eighteenth century. It was compiled by John

Hanbury, also known as Major Hanbury, who inherited the Pontypool furnaces and

forges from his father Capel Hanbury. The date of the manuscript is 1704, with

additions up to 1708;

it is now in the

Momnouthshire Record Office.

The reference to Melin‑y cwrt reads:

Oct. 6, 1708 began to blow at Neath or Melin Court furnace

(God Prosper) the hearth made with small stone such as we Make the boshes with.

Mem(orandum) the hearth was made half an inch wider than usual with great

stone.

It is possible that this reference

answers Phillips's query about the fate of the building of the furnace and its

original ownership. It is not known for how long Hanbury maintained his

interest in this furnace, but there is evidence6 that this small ironworks changed hands on a number

of occasions during the remainder of the eighteenth century until it closed in

1808.

The complete dependence of a blast

furnace upon water as the source of power, and the waterwheel as the prime

mover, has been revealed by Richard Warner,7 who was sufficiently perceptive to note a number of

interesting details during 1798 at more than one ironworks in South Wales. He

described the Melin-y-cwrt waterwheel as having a circumference of 120 feet,

which suggests a diameter of about 38 feet. He also made the point that the

works consisted of 'a blast furnace, a finery and a foundery'.

An engraving in J. G. Wood's The

Rivers of Wales, 1811

(Plate 1) provides a classical example of the water chute or launder taking the

water to the waterwheel which is housed beneath a part‑roof alongside one

wall of the furnace. The waterwheel activated a bellows inside the building,

which sent the blast through the side wall of the furnace to create the

required heat for the smelting operation. Above and behind the water chute is

the path or roadway along which the barrows of the time were trundled carrying

the raw materials, iron ore and charcoal, into the charging house where they

were made ready for loading through a charging hole in the top of the furnace.

The position of the actual blast

furnace was directly beneath the stack which is seen emerging above the ridge

of a pitched roof. The suggestion of a building rather than a furnace is given

by this type of roof, but the housing of a blast furnace within such a building

was not unusual during the charcoal-burning period. There is a very good

example of a furnace such as this at the present time in the village of Furnace

in Cardiganshire, one which was built in 1755.

The furnace was tapped at its front

wall and the molten iron flowed into the cast house which is immediately to the

left of the furnace building in the engraving, yet abutting on to it. The

remaining buildings undoubtedly contained the 'finery and a foundery' as

described by Warner. This implies that the pig iron which was produced in the

blast furnace was refined in another kind of furnace into wrought iron and thus

made capable of being shaped under a tilt hammer in that part of the ironworks

which was the forge. It also means that pig iron in its solid form was melted

in a cupola so that, in its molten state, it could be poured into moulds of

different kinds to form castings of iron of various shapes. There were,

therefore, essential differences between pig iron, wrought iron and cast iron.

At this time—the end of the

eighteenth century—the proprietors of Melin-y-cwrt ironworks were

probably finding it extremely difficult to sustain the momentum of previous

years. Charcoal, or supplies of timber for turning into charcoal locally, came

from outlying areas, which added to production costs. Inevitably the rapid

development of new ironworks, using coke as a fuel, on the north-east rim of

the South Wales Coalfield, led to the closure of charcoal furnaces such as

Melin‑y‑cwrt.

The year 1667 has been given as the

year when a forge was erected near the Dulais waterfall. Afon Dulais is a

tributary of Afon Nedd, and flows into the main river from the north‑east.

There is little doubt that there was a subsequent connection between this site

and a rolling mill and tinplate works which was developed at Ynys‑y‑gerwn.8 Although tinplate was at this time

iron sheet coated with tin, the Ynys-y-gerwn works does not come within the

scope of this chapter. The works which was developed near the Dulais waterfall

does, because it was originally an iron forge concerned with converting pig

iron into a refined iron for hammering and rolling. A lease of 1768, involving

Coles, Lewis & Co., refers to 'Dylais Forge Houses', and Warner9 in 1798 called it the Aberdilis

(sic) forge, 'where the crude or pig iron is formed into bars and sent in that

state . . . farther up the valley . . . to be manufactured into tinplate'.10 A question which cannot be answered

with any certainty is what was the source of the pig iron worked at Aberdulais

Forge. It could, of course, have come from a number of ironworks. In 1782 the

Aberdulais Forge was owned by John Miers,11 who was also interested in forges in the Afan and Tawe

valleys. Miers died in 1786, but it is assumed that the forges were afterwards

managed by his son John Nathaniel Miers, who married a daughter of Richard

Hill, of Plymouth Ironworks, Merthyr Tydfil. It is, perhaps, reasonable to

suppose from this ir formation that at one time the Plymouth works was a source

of pig iron for Aberdulais.

A visit during May 1973 to this site

revealed that there had been a steam engine operating there at one time: the

now picturesque boiler house stack is still standing. The rolling mills at the

works would have been driven from such an engine. The site is now overgrown,

and most of the masonry ruinous, but it can still provide evidence of the use

of water power. A stone staircase from the main works' area leads upwards to

the point where the water-course tapped Afon Dulais above a weir. The water

flowed along this water-course to a point above an overshot waterwheel, which

was without doubt the prime mover for the original forge, particularly the tilt

hammer. The wheel‑pit remains and also a good‑looking, stone

structure which carried the water chute from the water‑course to the

point above the wheel. This structure, as it stands today, consists of three

archways, one at the front and one on each side, which were strengthened by the

use of double arches in each case. The stonework of this part‑building

cannot be faulted.

There is some evidence that another

furnace was built in Cwm Nedd towards the end of the eighteenth century. It was

Alexander Raby's furnace at Penrhiwtyn.12 At this time coke was the fuel generally used in blast

furnaces in South Wales, but there is no evidence to prove that this was such a

furnace. In all probability it was short‑lived as an ironmaking venture.

The best‑known of the

ironworks in the Neath area is the Neath Abbey Ironworks, which was developed

from an original site at Cwm-y-Felin, where Richard Parsons is known to have

operated a blast furnace and a forge during 1785‑92.13 There is, however, a map of a

'Survey of the Neath Abbey Estate 1770-177114 which shows 'Old Pond and old Rowling Mills'. The early

works, which is now a woollen mill, was sited on the east bank of Afon Clydach

at SS 738932. It was served by a waterwheel which was operated from a

watercourse which tapped the river above a weir a short distance upstream. The

housing of this wheel is still recognisable alongside a wall of the present‑day

mill.

In 1792, Parsons leased the

Cwm-y-Felin property to the family of George Coker Fox of Falmouth and their

associates, two of whom subsequently were Peter Price and Samuel Tregelles.15 It has been said of this Cornish

Quaker family and their ironworks 'that they never tried to grow large',16 but were content to develop slowly

'. . . ever mindful to turn out work of the best make'. The subsequent history

of this company will show that it lived up to its recognition of the need for

quality production.

A fairly close look at the Neath

Abbey Ironworks has been made possible by the information and illustrations

which appeared in a diary kept by John Gilpin, an American, who visited the

West of England and South Wales during 1796. Gilpin's material has become

available through the kindness of A. P. Woolrich of Bristol, a member of a

number of societies interested in the history of science and technology, who

has spent a great deal of time in transcribing patiently the entries in the

diary from a microfilm of it which became available to him. The inclusion of

this new material about Neath Abbey Ironworks has been made possible by his

work.

Gilpin visited the works for the

first time on 3 August 1796 and described them as, 'A new sett of iron works

finished within these times' owned by George C. Fox and Company of Cornwall.

They existed 'for the simple purpose

of making Pig Iron and some castings and have been erected here for the

contiguity of iron and Coals'. This makes it clear that there was a foundry on

the site at this time.

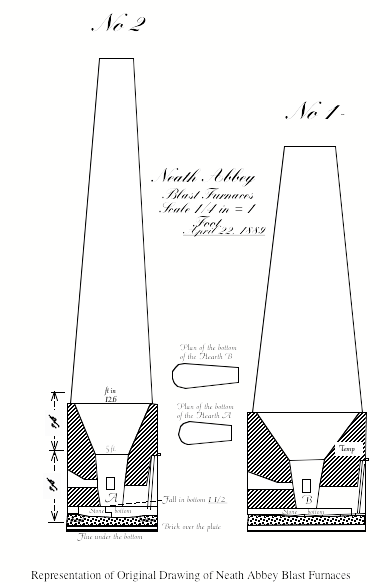

The works was described as modern in

its construction, the furnaces being very large, and blown by one Boulton and

Watt steam engine. Gilpin stated that the blast furnaces were about 60 feet

high, the two of them producing from 75 to 80 tons of iron per week. The

original drawing of the two furnaces has been deposited at the Glamorgan Record

Office,17 and shows

that Number One furnace was about 53-1/2 ft. high and Number Two 65-1/2 ft.

In 1798, the furnaces were described

by a well‑known traveler of the period, Richard Warner,18 already referred to, as '. . . Two

immense blast furnaces belonging to Messrs. Fox & Co.... constantly at work,

each of them producing upwards of thirty tons of pig‑iron every week.

They are blown by iron bellows, worked by a double engine, constructed on the plan of Messrs.

Boulton and Watts, with a steam cylinder of forty inches in diameter'.

Warner's description provides an

extra piece of information in referring to the double engine, but both travellers provide

information which suggests that there had been no great increase in the tonnage

of iron produced between 1796 and 1798.

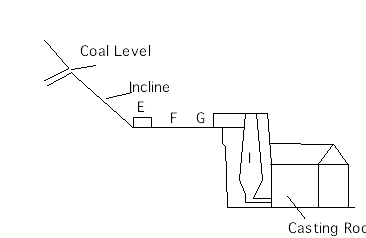

Gilpin's Diary contains a number of

sketches which provide valuable information about the lay-out of the ironworks,

and a certain amount of detail about processes which were contributory to

ironmaking. Among these is a 'profile plan' (see page 156) relating the

position of the works to the high ground behind to the west. In the diary this

sectional drawing follows a sketch of the ground plan, but it is advantageous

to look at it first so that the works may be immediately related to the source

of supply of one of its raw materials, coal, which was made into coke.

The sketch shows that the furnace

was built into land which rose above the ground level of the ironworks where

stood the melting house, or the cast house, as it is more familiarly known.

This made it possible for the raw materials—the iron ore, the coke and

the limestone—to be prepared on the same level as the furnace top and in

line with the charging platform of the furnace, shown as F and G in the sketch,

and the charge hole in the furnace stack. This principle can still be

recognised in the remains of other sixteenth and eighteenth-nineteenth century

blast furnaces on a number of sites in South Wales.19 The shed or 'upper part of the

furnace', G, was often called the charging house because the raw materials were

proportioned, according to their weight, in this building. That part of the

blast furnace shown as I and called 'the flue of the furnace' is more commonly

known as the shaft.

This sketch perhaps over‑simplifies

the connection between the furnace area and the coal level, but it does reveal

that coal and iron ore, worked in levels, were conveyed to the furnace yard in

trams on tramroads. Coal for the ironworks came from levels driven into the

hill to the west of the works. Gilpin calculated that the level which he visited

was about 500 yards away from the blast furnace.

Profile

Plan

One of the sources of iron ore is

given as Pantyvan, probably Pontneathvaughan (Pont‑nedd‑fechan) from where it was

transported about '13 miles down the canal'. In addition, iron ore came from

the neighbourhoods of Merthyr and Brecon, and also from Lancashire. The

Lancashire ore Gilpin described as being very fine and requiring no roasting.

It is interesting to note that iron ore was being imported into Neath at this

time from Lancashire, probably Furness, because the ironworks at Tintern were

also using Lancashire ore during the second half of the eighteenth century.

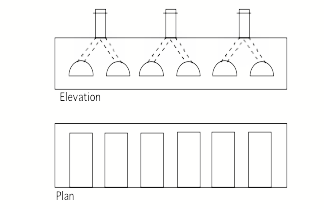

The sketch of the ground plan of the

furnaces and the area behind it shows more clearly the relationship between the

two furnaces at Neath Abbey and the preparation area (illustrated on page 157).

It also emphasises the importance of

this area to the ironmaking process. The kilns for roasting or calcining

the iron ore, shown as E, were important because they cleaned the ore through

the burning of the unwanted particles of earth, and a thorough drying also

resulted. It is significant that limekilns are not included in the preparation

area. It is usual to find them on sketches and drawings such as this one, but

there were works which located their kilns outside the main area, but not too

far distant.

In the light of Gilpin's sketches

there are a number of points of interest in the area above and behind the old

furnaces as it is today. It is significant that there is a very high embankment

with stone retaining walls on the west side of the roadway which goes up the

side of the hill to the west of the furnaces. There is no doubt that this

embankment was joined to the furnaces by two bridge arches. The present height

of the embankment and of the charging platform levels of both

furnaces—the charge‑hole of Number Two furnace still

remains—provide unmistakable evidence of this.

Ground

Plan of Furnaces

and Preparation Areas

In a profile sketch showing the

location of the calcining ovens (E on the plan sketch), Gilpin describes this

area as 'The Hill levelled for a yard to contain the stone ore'. This area is

now used by a transport firm, but it is still possible to appreciate the

considerable 'levelled' area which was available to the ironworks for the

preparation of the raw materials for the furnaces.

Gilpin calculated that the coal

level which supplied coke for coking was some 500 yards from the furnaces. It

is significant that there is a ruined building about this distance away from

the furnaces at the western end of the embankment and at a point where the land

begins to rise. This could have been the point of entry to the original level

where subsequently a steam engine was installed.

In 184120 the Neath Abbey Coal Company was

operating an eight horsepower steam engine at a pit '. . . entered by a level'.

It was the Pwllfaron Colliery, where 61 were employed, three under thirteen

years of age. The proprietors were listed as Messrs. Price and Co.

A stone building, now used as

offices, which may have had some administrative function during the period of

the ironworks, stands on the south side of this rise in the ground a short

distance away from the embankment.

The existence of 'beds for coaking

Coal', shown as G on the ground plan, suggests that coke, in bulk, was made

from coal banks which operated in the open air and not in ovens. Gilpin

described this operation of 'coaking' as one which was carried out by using

lump-coal, placed in long beds, which, after it had burned for about twelve

hours, was covered with earth to put out the flame.

Coke

Ovens

The feature shown as F, however, indicates

that coke ovens were used for converting small coal into coke, and this was '.

. . only done to prevent waste'. The work was carried out by 'women labourers

who operate every part of it by their own knowledge and experience'. Two

sketches, one in plan and one in section, indicate that these were narrow ovens

made of rectangular chambers covered with brick archways. They were usually

built alongside each other, being separated only by their brick dividing walls.

They were blanked off at one end—this gave the name 'stop‑ended'

ovens—and were charged by hand from the front where there was a lifting

door made of cast iron. Each one, as indicated in Gilpin's sketch, was provided

with a flue in the roof to induce the necessary draught and to provide an escape

for the gas which was generated. The remains of a line of such coke ovens may

still be found on the site of the original Dowlais Ironworks in Merthyr Tydfil.

There is no precise indication of

the way in which the blast was blown into the furnaces from the engine. The

ground plan merely indicates the links between AA, the steam engine, B, air

bellows, and C, the two furnaces. It is assumed that the links, the double

lines as shown, are the cast iron pipes which carried the blast into the tuyeres,

removable devices

in the furnace walls into which were fitted the nozzles from the end of the

blast pipes. It is not possible to draw particular conclusions from a sketch

which is not to scale, but it is more than useful to have this lay‑out

and to compare it with the two blast furnaces at Neath Abbey as they stand

today.

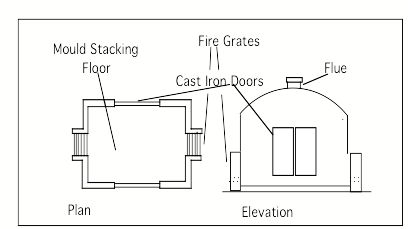

The 'store for drying moulds', H, is

significant because it points directly to a substantial involvement in iron

founding at this time. The making of sand moulds from wooden patterns by hand was

and remains a skilled art, and it was necessary to dry the moulding boxes

before they were ready to receive the molten iron. The dimensions of the drying

store as shown in the ground plan and compared with the cast houses (shown as

'Casting Room') suggest that an appreciable amount of space was needed for this

side of the work.

The drawings of the stove used for

baking or drying the moulds in the drying store represent nothing more than

typical installations of this kind, but the interesting fact is that it is now

possible to record them as integral features in iron founding at Neath Abbey at

the end of the eighteenth century.

Drying

Stove

The tuyere was the important link between the blast

engine and the furnace, and it is extremely rare to find examples of this

feature in the remains of furnaces of the eighteenth-nineteenth century period.

Two such examples may still be found in the neighbourhood of Neath, the first

is in furnace Number Two at the Neath Abbey Ironworks site, and the other at

the site of the old Venallt Ironworks, Cwmgwrach.

The two furnaces at Neath Abbey (one

illustrated in Plate 3) still provide classic examples of stone blast furnaces

which were linked at the charging level with the higher ground behind by bridge

arches. The back walls of the furnaces were usually separated from the rising

ground behind them by a passage‑way. It is an interesting experience to

stand in this passage-way (illustrated in Plate 4) behind the two furnaces at

Neath Abbey because one side of it, the one which is parallel to the back walls

of the furnaces, is solid rock. It is customary to find a retaining wall

extending from ground level to the charging level as one side of such a passageway,

but it is unusual to find one that is composed of natural rock. The wall was

considered necessary, not only as a retaining feature in the rising ground, but

also as a precaution for keeping the natural dampness away from the furnace.

In the side walls and back walls of

furnaces of this period there were arched openings leading into small chambers.

Each one was known as the tuyere house. The protection afforded by the roof and walls of the tuyere

house, an integral part

of the furnace structure, was essential because the great heat of the furnace

made it necessary to change the cast‑iron tuyere regularly, and so the small chamber

was very important. In a side wall of the Number Two furnace at Neath Abbey it

is still possible to see the broken end of a tuyere; it is likely that the blast pipe was

roughly broken off at this point when it was removed (illustrated in Plate 5).

There is a tuyere house in the back wall of each of

the Neath Abbey furnaces, and directly opposite each one there is a small

chamber which was hewn out of the solid rock. The purpose of these two chambers

in relation to the working of the furnaces is not exactly clear, but they may

have been necessary to provide room for the removal and fixing of the blast

pipes. The chambers are roughly semi-circular, the entrance being 11 ft. wide,

7 ft. high, and the distance from the front to the back about 18 ft.

In the front walls of the furnaces

of this period there were two holes, the one when it was tapped releasing the

slag, and the second the molten iron into a channel leading to furrows which

had been formed in the sand floor of the cast house, a floor which sloped

gently away from the furnace to facilitate the easy flow of the molten iron

into the furrows. The holes were tapped by the founders or furnace‑men,

who used cast-iron rods. A working aperture in the front wall, appreciably

larger than the tuyere house, gave access to the tap-holes. This had an arched entrance, but

its roof sloped upwards and outwards from the tap holes. It was strengthened by

iron lintels which were built into the masonry. The two furnaces at the Neath

Abbey Ironworks site provide the best, if not the only, remaining examples of

such complete working apertures and their iron lintels' reinforcements on the

site of an old ironworks in South Wales (illustrated in Plate 6).

There is a small amount of

information available about the ironworks in 184121 when it was described as 'Neath Abbey Iron Company,

parish of Cadoxton, county of Glamorgan—Messrs. Foxes, Price and

Co., Proprietors'.

The numbers employed were listed as:

Adults .. .. .. .. .. .. .. ..

175

Under 18 years of age .. .. .. .. .. .. 47

Under 13 years of age .. .. .. .. . . 11

In the words of Charles Waring, the

works' agent at this time, 'The Neath Abbey Iron Company is an engine

manufactory, and contains a department for iron ship‑building, &c.

Our works have no special provision for ventilation but they are sufficiently

airy; and the usual temperature is from 58¡ to 70¡, nor is any great degree of

heat required in those processes where children are employed . . . We have

about 170 adults at work now, but when we are full of work we employ from 260

to 300. Our two blast furnaces are not at work'.

Boys of 11, 12, 13, 14 and 15 years

of age were variously described as fetter tender, moulder's attendant, general

attendant, attendant on the furnace, and one as attending upon the men in the

boiler-making and iron ship-building department.

There is no doubt that the

collection of plans and drawings of the Neath Abbey Ironworks at the Glamorgan

Record Office is among the finest of its kind in Wales. A large number of

admirable ink and water-colour drawings testify to the remarkable engineering

achievements of this works and reveals an almost incredible contribution of

plant and machinery to a variety of industries.

The index to the collection is

divided as follows:

1. Plans of Shipbuilding and Marine

Engineering 1817-83. 737 plans, 6 papers, 3 files.

2. Plans of Locomotives and Railway

Engineering 1826-92. 444 plans, 1

file, 1 paper, 1 photo-copy.

3. Plans of Machinery

1792-1882. 886 plans, 1 file, 4

papers, 1 photo-copy.

4. Plans of Neath Abbey Ironworks

1813-81. 116 plans, 2 files, 1

paper.

5. Plans of Gas Installations and

Work for Gas Contracts. 377 plans, 2 papers, 4 files.

That this collection has been

preserved22 is of great

importance, because it provides details of the contributions made by the Neath

Abbey Ironworks in so many fields of manufacture. Only a small number of these

plans are relevant to this chapter, but a study of the lists has revealed that

other ironworks in South Wales looked to Neath Abbey for plant and machinery.

Locomotives were made for the Gadlys Ironworks in Aberdare, the Nantyglo

Ironworks, Cyfarthfa Ironworks, Hirwaun Ironworks, Dowlais Iron Company,

Sirhowy Ironworks, Rhymney Iron Company and the Plymouth Iron Company.

The Plans of Machinery 1792-1882

include not only plans of beam engines, winding and pumping engines, and

various machinery mainly for collieries, ironworks and tinworks, but also for

brickworks, canals, cement works, chocolate works, copper works, docks, flour

mills, gold mines, potteries, silver mines and waterworks, as well as engines

and machinery for general sale. A number of the ironworks already listed were

among those which were supplied, and the various types of machines and engines

supplied indicate that the Neath Abbey Company was heavily engaged in foundry work

and engineering.

The Plans of Neath Abbey Ironworks

from 1813 to 1881 are of particular interest because some of them relate to the

buildings on the site which have survived to the present time. The complete set

includes ground plans of the Neath Abbey Ironworks, plans of buildings,

inventories of stock, and of engines and machinery for the furnaces, boring

mill, fitting shop, rolling mill, wharf and of the Cheadle Works. This was a

short distance away to the south near the mouth of Afon Clydach, with the

company's dry dock alongside. There are also plans relating to the Neath Abbey

Gas Works which was on the east side of the main works.

An undated plan shows the forge, bar

mill, tin mill and the tail race. The forge and bar mill measured 90 ft. by 44

ft. 6 inches, and the waterwheel, which operated a tilt hammer, was 16 ft. in

diameter. The hammer was designed '. . . to strike 80 to 90 blows each minute'.

At the same time there was a mill in operation—the drawing signifies that

the length of a mill beam was 20 ft. and the speed of the rolls 20 revolutions

per minute.

One of the most interesting of the

drawings of the works' buildings is 'A View of the Roof of the New Fitting Shop

at Neath Abbey Iron Works', to a scale of 1/4 in. to 1 foot. This drawing,

which is dated 20 October 1818, lists the Cast-iron stays, the Purlins, the

King post of Wrought Iron, the Tie Beam of D¡, the Centre Piece, D¡ the

Principles, a piece of Timber under the Principles, a plan of Principles and

Purlins. Each item

is shown in fine detail in this ink and water-colour drawing.

A roof structure such as this one

may still be seen in the only complete original building which remains, apart

from the two blast furnaces, on the main site. The apparent lightness of the

structure's members is surprising in view of the heavy slate roof which it

supported and still does. It has been in position for nearly 155 years, which

is in itself a tribute to its design and manufacture.

A plan of this building, called the Fitting-up

Shop, is shown in a drawing from the same

collection dated 22 July 1850. The drawing shows another building, the Smithery

and Boring Mill alongside

it, and between the two a water course in an Iron Trough leading to a water cistern and

waterwheel. The second building no longer stands, but in the west wall of the

building which remains there is a run of cast iron angle-brackets which carried

the water-trough, and it is still possible to identify the housing of the

original waterwheel which was operated from the water. The Fitting-up Shop measured 89 ft. by 46 ft., and the

other building 65 ft. by 46 ft. The drawing also shows a Pattern Makers'

shop, 85 ft. by 42

ft. 6 in.

Unfortunately there is no detailed

plan of the complete site, but the first edition of the Ordnance Survey map, 25

inches to 1 mile, surveyed in 1876,23 shows that there were buildings on those parts of the site

which are now open areas.

It is worth recording that there is

a set of plans for Forge, Cwm y Felin. They are dated 1825, 1827, 1841 and 1854, and were

for a roof for the forge, shaft for the waterwheel, castings for the air

chafery and crank rod of shears. These plans indicate that the original site

continued to remain as an active part of the works as it developed. A

continuing dependence on water power is also indicated in plans for two

cast-iron trunks 'for building in the dam of the pond', 22 May 1840, a 'grating

for sluice of pond', 20 May 1841, and 'water-wheel for driving fitting-shop

machinery', 23 April 1878. This was the wheel served with water from the iron

trough. This was an additional source of power, for the plan of 1850 shows a

steam engine in the Fitting-up shop.

On view in the Department of

Industry at the National Museum of Wales there is a part of a cast iron pillar,

161 inches in diameter, inscribed:

N.

ABBEY

1800

Two such pillars were used to

support the roof structure of the Margam Copper Works when it was built in

1800. They came to light when the building was demolished in 1964. The works

were occupied by the Briton Ferry Steel Co. Ltd., in 1926, and were known as

the Vivian Tinplate Works. The pillars provided good examples of the

large-scale castings which were produced at the Neath Abbey Ironworks.

The site of the old ironworks at

Cwmgwrach, the Venallt Ironworks, originally probably Y Wenallt, is especially sign)ficant because in a

large mass of iron and slag there remain side by side the section ends of a

pair of tuyeres (illustrated

in Plate 7). It is probable that when production ceased, the charge in the

bottom of the furnace was left to solidify. Subsequently the stonework of the

furnace and the blast pipes from the engine house were completely removed, but

the solid mass and the twin-tuyeres have remained, possibly because their removal would be a

formidable task, and it is fairly certain that they have remained where they

are for more than a hundred years.

There are also on the site the

remains of a typical nineteenth-century engine-house and boiler-house stack

(illustrated in Plate 8). The site is shown on the 6 inch to I mile map, 1901,

as a disused works, but on the 25 inch to 1 mile map, 1876 Glamorgan 105, as

Venallt Works (patent fuel). It is fairly obvious that the engine house was

altered in various ways to meet the requirements of this process. Behind, and

far above, the iron and slag mass there is a typical stone charging platform

built into high ground; its retaining wall was the back wall of the passage-way

behind the Venallt blast furnace.

Unfortunately it has not been possible

to obtain more than a little information about this works. It may have been

established as an ironworks, that is, an ironmaking works, on the site of an

iron-using works, a foundry or forge, which was started in 1826.24 The blast furnace was producing in

1842, and there may have been a connection with the Neath Abbey Ironworks. In

1844 it was owned by Jevons and Wood, who suffered heavy losses, and after 1854

the proprietors of the Aberdare Company (Fothergill and Darby) were the owners.

Between 1854 and 1860 it was listed25 as a works of two blast furnaces which were not in

production. During 1861-63 they were listed as furnaces which had been

demolished. A thorough investigation of this site during 1971 failed to reveal

any evidence of a second furnace.

The Venallt furnace is of

considerable interest because it used anthracite coal as fuel in the smelting

process. George Crane, the owner of the Ynyscedwyn Works, Ystradgynlais, had

succeeded in using anthracite for this purpose in 183626 with the assistance of hot blast,

that is, blast which on its way to the blast furnace had been heated in a stove

made up of a series of heated pipes. Crane addressed the appropriate section of

the British Association on his discovery when it met at Swansea in 1838.

A writer on iron manufacture during

the mid-nineteenth century period27 argued that the proportion between the throat of a blast

furnace and its diameter was more important than heating the blast before it

entered the furnace. He wrote, 'We have only to go from Hirwaun to the Neath

Valley to see the beneficial effects on the coal which would follow from an

inconsiderable enlargement of the throat.' It would be interesting to know

whether this prolific writer, whose theoretical and practical consideration of

iron manufacture covered the main ironworks of Britain, had proved this point

at the Venallt blast furnace in Cwm Nedd.

References

1 D. Rhys Phillips, 1925, A

Romantic Vallcy in Wales . . . Thc History of thc Vale of Ncath,

pp. 285‑309.

2 D. Rhys Phillips, op. cit., pp. 286, 294‑299.

3 See page 163.

4 Phillips, op. cit., p. 294.

5 H. R Schubert, 1957, History of

the British Iron Industry from 450

B. C. to A.D. 1775, p.

425.

6 Phillips, op. cit., pp. 295‑299.

7 Rev. Richard Warner, 1813, Second

Walk Through Wales in August and September 1798, pp. 101‑2.

8 Phillips, op. cit., pp. 299‑304; and E. H. Brooke,

1944, Chronology of the Tinplate Works of Great Britain, p. 166.

9 Brooke, op. cit., pp. 8-9.

10 Phillips, op. cit., p. 301 from Warner, pp. 98‑101.

11 John Lloyd, 1906, Old South Wales

Ironworks, p. 104.

12 Phillips, op. cit., p. 305.

13 Ibid., p. 288.

14 Dynevor Collection, Glamorgan County Record Office.

15 Phillips,

op. cit., p. 289.

16 Lloyd, op. cit., p. 102.

17 Neath Abbey Collection, Glamorgan

County Record Office.

18 Warner, op. cit., pp. 96-97.

19 D. Morgan Rees, 1969, Mines,

Mills and Furnaces, pp. 52‑87.

20 Children's Employment Commission,

1842, Vol. 17, p. 566.

21Children's Employment Commission,

1842, Vol. 17, p. 564.

22 This was made possible by Mr. A. W.

Taylor, who deposited the collection for Taylor and Sons (Engineers) Ltd.,

Briton Ferry,in 1966 at the Glamorgan County Record Office.

23 Also at the Glamorgan County Record

Oflice.

24 Phillips, op. cit., p. 307.

25 Robert Hunt, Mincral Statistics,

1854-60.

26 D. Mushet, 1840, Papers on Iron

and Steel, p. 424.

27 W. Truran, 1862, The Iron

Manufacture of Creat Britain, p. 179.