46 Evans, "Account," Archives of Useful Knowledge,

volume 2 (1812), page 364.

47Aurora, 25 June 1812.

48 Niles' Weekly Register, Volume 1 (1 February 1812), page 407.

The "chief artist," Isaac Sanford, patented a 'Frances Trollope,

Domestic Manners of the Americans, edited by Donald Smalley (New York, 1949),

page 376.

49 Hutton, "First Engines," Transactions of the

American Society of Mechanical Engineers, volume 15 (1894), page 984; Hunt's

Merchants' Magazine, volume 34 (June 1856), page 673.

50 Minutes, Providence Iron Foundry, 21 June 1827, volume 1,

Slater collection, Baker Library. Harvard University, Cambridge, Massachusetts;

H. N. Slater to William Tiffany and Company, 5 March 1830, letter book, volume

14, Steam Cotton Manufacturing Company, Slater collection, Baker Library.

51 McLane Report, volume 1, page 927.

52 Edward S. Wilkinson to Elisha Dyer, 16 December 1861, in

Transactions of the Rhode Island Society for the Encouragement of Domestic

Industry ... 1861, page 88.

53 Niles' Weekly Register, volume 48 (8 August 1835), page 397.

54 Woodbury Report, pages 88-89; Scientific American, volume 5

(20 July 1850), page 346.

55 Hunt's Merchants' Magazine, volume 34 (June 1856), page 673.

56 McLane Report, volume 1, page 927.

57 Hunt's Merchants' Magazine, volume 34 (June 1856), page 673.

58 Quoted in Morrill Wyman, "Memoir of Daniel

Treadwell," Memoirs of the American Academy of Arts and Sciences, volume

11 (1888), page 344.

59 Deposition of Amos Binney et al., 7 February 1818, in John L.

Sullivan, Explanation, by John L. Sullivan, of the Nature of Certain Grants to

Him for the Use of Steam, Boats on Connecticut River... (no place, 1818), page

31.

60 Woodbury Report, pages 41-44, page 354.

61 Copeland, Cotton Manufacturing, page 28n.

62 Niles' Weekly Register, volume 35 (31 January 1829), page 366.

63 Zachariah Allen, Science of Mechanics, page 352n; H.N. Slater

to Major Durfee, 18 July 1830 and Samuel Slater to Delaware and Hudson Canal

Company, 23 April 1831, letter book, volume 14, Steam Cotton Manufacturing

Company, Slater collection, Baker Library.

64 Niles' Weekly Register, volume 61 (29 January 1842), page 352.

In 1840 a New York City editor claimed that he knew of no stationary engine in

that city in which fuel other than coal was used. American Repertory, volume I

(March 1840), page 136.

65 John Grammer, Jr., "Account of the Coal Mines in the

Vicinity of Richmond, Virginia," American Journal of Science, volume 1

(1818), pages 125-130.

66 Hunt's Merchants Magazine, volume 15 (August 1846), page 213.

67 Woodbury Report, pages 20, 27, 30-31,33.

68 Samuel Webber, Manual of Power for Machines, Shafts, and

Belts, With the History of Cotton Manufacture in the United States (Revised

edition, New York ' 18 7 9), pages 50-51.

69 John Clowes, "Steam and Water as Motive Powers,"

National Magazine and Industrial Record, volume I (October 1845), page 448.

70 Scientific American, volume 4 (12 May 1849), page 269.

71 Clowes, "Steam and Water," National Magazine and

Industrial Record, volume 1 (1845), pages 448, 444.

72 Woodbury Report, passim. It should be noted that engines were

more conveniently counted in cities than in rural areas, a fact which no doubt

prejudices these figures somewhat. As noted above, Louisiana was an exception

to this rule of urban use.

73 Ibid., page 162.

74 Ibid., page 156.

75 Niles' Weekly Register, volume 40 (16 July 1831), page 344;

Job R. Tyson, "Resources and Progress of Philadelphia," De Bow's

Review, volume 15 (July 1853), page 48.

Chapter

7

(pp

94-99)

The

Industry Established

In

arranging the power for the Newark

Machine

Works, I procured an engine

of

about 35 horsepower. . . of good con-

struction....

With this engine we drive

14

lathes for iron, 3 for wood work,

4

planers for iron, and one . . . for wood;

4

drills and one boring and one tenoning

machine,

splinter and bolt cutters, two

circular

saws, punching and shearing

machines,

two trip hammers, a large

blacking

mill, and fan --blower

for forges

and

foundry....

JOSEPH

E. [HOLMES (1855)1

Just as the number and the

use of steam engines expanded enormously during the Jacksonian period, so did

the making of engines become widespread and systematized. At the end of the War

of 1812, engine-makers were few and were concentrated in the three centers of

New York, Philadelphia, and Pittsburgh. By the middle of the century, engine

shops were found in nearly every sizable town in the country. A general

knowledge of steam was even more widely spread. At the turn of the century, the

venerable iron manufacturer and mill designer John Fritz reminisced that when

be became an apprentice in a Parkesburg, Pennsylvania, blacksmith's shop in

1838, he discovered that his new master had built his own steam engine. Fritz

wrote that in those days a mechanic in like circumstances "would have to

make his own drawings and patterns, make his own forging, and fit the work all

up, without tools, except makeshifts. Today, as many men work on an engine as

there are parts to it, and each man has a special machine, specially designed

to do his work on."2 The significant point is not that a small‑town

blacksmith had to improvise in building an engine in 1838, but that he could

even build a workable engine.

The Middle Atlantic States remained

the center of American engine building throughout the first half of the

nineteenth century. Philadelphia had 174 steam engines in 1838, of which at

least 133 were built by the forty-four local makers then listed as having

engines operating within the city. Rush and Muhlenberg successors to Oliver

Evans—had the largest local trade and were, along with Daniel Large, the

only holdovers from the earlier period. Twenty men were listed as having made

only one engine each, indicating that it was not uncommon for a handy mechanic

to make an engine on occasion, without having any particular connection with

engine building as a business. Among the engine builders mentioned in the

Philadelphia city directory for 1840, only one called himself a "steam engine

maker," the rest preferring the title "machinist" or

"machinist and iron founder."3

In addition to its fame as a

center of engine and machine building, Philadelphia by the 1850s had also made

a reputation in the closely allied manufacture of iron ships. Fabricators of

steam boilers, having the necessary equipment and experience in working sheets

of iron, pioneered in the building of iron ships in this country. One of the

largest firms in this business was Reaney, Neafie, & Company, which was

formed in 1844 by two mechanics, Thomas Reaney and Jacob G. Neafie. The latter

had been an apprentice of Thomas Halloway, a prominent stationary engine

builder of the city. John Roach, perhaps the most famous iron shipbuilder of

postwar Philadelphia, moved to that city after serving his apprenticeship

in New York under James P. Allaire.4 His exodus from New York was

not surprising for while New York City continued to be the center of

traditional wooden ship construction, the building of iron ships along the

Delaware River was earning it a sobriquet as the "American Clyde."

LEADING

PHILADELPHIA ENGINEMAKERS—18385

|

|

Number

of Engines Operating

|

|

Enginemakers

|

in

Philadelphia in 1838

|

|

Rush and

Muhlenberg

|

26

|

|

Levi

Morris

|

24

|

|

Hyde and

Flint

|

15

|

|

M. H. Baldwin

|

12

|

|

Stacy

Costell

|

10

|

|

Thomas

Halloway

|

7

|

|

James

Brooke

|

6

|

|

Daniel

Large

|

5

|

|

Prosper

Martin

|

4

|

|

James T.

Sutton

|

4

|

Starting in the 1830s,

Philadelphia engine-makers also gained a considerable reputation for the construction

of locomotives. This success can be traced to the wide knowledge of stationary

engines already possessed by local mechanics. Oliver Evans' early idea of

building workable steam carriages for use on common roads had never completely

died. About 1828 a group of promoters built a carriage at the machine shop of

Nicholas and James Johnson in Kensington. This low-powered vehicle had a single

cylinder, set horizontally, with connecting‑rod attachment to a single

crank at the middle of the driving axle. The machine was abandoned after a

faulty steering device caused it to careen into a shop window.6

The real stimulation to

activity, however, was the announcement in 1831 that trials had been scheduled to

select a locomotive for Baltimore and Ohio Railroad service. A number of makers

of stationary engines in Philadelphia entered the competition. Stacy Costell,

already famous for engines he had built with vibrating cylinders, now built a

locomotive with two six-inch cylinders of twelve-inch stroke. It was tried out

later on the Columbia Railroad, after which it was broken up and the boilers

set to work supplying a stationary engine. Thomas Halloway, another prominent

builder of stationary engines, also began a locomotive for the trials, but it

was never finished.7

The most famous Philadelphia

engine builder was Matthias Baldwin. Starting as an apprentice with the jewelry

firm of Woolworth Brothers, he later became a machine-maker specializing in

engraved copper rolls for calico printing. Baldwin made an engine for his own

use in 1827 and then built engines for sale; this trade "became extensive

and profitable." He became interested in the Baltimore and Ohio trials of

1831 and later became one of the world's leading manufacturers of locomotives.

Joseph Harrison, another

leading Philadelphia locomotive builder, also had a background in stationary

steam engine construction. At the age of fifteen he was apprenticed to an

engine builder named Frederick D. Sanno. When Sanno's business failed, Harrison

went to work for James Flint of the firm of Hyde and Flint. Before his

indenture had run out, he became foreman of this shop at the age of twenty-two.

After working for a time with the locomotive builders and innovators William

Norris and Colonel Stephen H. Long, he was hired as foreman by Garret and

Eastwick, another Philadelphia engine-building firm. He became a partner in the

enterprise, which soon began building locomotives. Between 1844 and 1851 he

built railroad equipment in St. Petersburg, Russia. Samuel Wright, who had been

an apprentice with Harrison in the shops of Flint and Hyde, joined with the

stationary engine-maker James Brooke to make two experimental locomotives.8

Other Philadelphia

experimenters built one or more locomotives during this same period, but the

construction of railroad engines quickly became a separate branch of the

machine-making trade. Most of those stationary engine-makers who took an early

fling at locomotive construction came to realize that there was more to it than

merely placing an engine on a cart and soon went back to their familiar work.

The industry, nevertheless, took firm root in Philadelphia, and Harrison wrote

in later life that the city's workers "can be found everywhere, and for

nearly forty years Philadelphia skill has been sought for to fill responsible

places in all parts of the United States, in the West Indies, in South America

and in Europe, and even in British India."9

To a lesser degree,

stationary engine-makers in other cities went through the same pattern of

trying their hands at building locomotives. In Boston, Holmes Hinkley made the

transition smoothly and gained a wide reputation for the excellence of his

engines. The pioneer Pittsburgh firm of McClurg, Wade & Company built five

locomotives between 1834 and 1837, but then relinquished this line of work.

Minus Ward of Baltimore saw in the locomotive a possible use for his patented

rotary engine and conducted several trials before giving up the enterprise In

New York, William James, a large-scale maker of stationary engines,

experimented in 1833 with a steam carriage, "Calculated to run on a common

turnpike road, also adapted to railroads."10 They, like most of

the Philadelphia makers, soon gave up building this type of engine.

Unlike Philadelphia, New York

City did not become a center of locomotive building, but it continued to

produce large numbers of marine and stationary engines. Charles Stoudinger's

former partner James P. Allaire, who upon Fulton's death purchased his works,

continued for many years to be one of the leading engine-makers of the city.

His business increased so fast that during the 1820s he purchased some eight

thousand acres of timberland at Howell, New Jersey, to ensure a supply of

charcoal iron for his enterprise. After an initial success, this proved to be

an ill-advised move when, in the 1840s, Pennsylvania iron made with anthracite

gained wide preference for use in general machine work."

Allaire's New York works

employed approximately six hundred persons in 1831 and by 1847 his plant

produced two hundred thousand dollars worth of iron goods. It continued in the

manufacture of steam engines and boilers, heavy machinery, and a general

machine business, but by 1853 it was principally engaged in building engines

for ocean, lake, and river steamers.' 12

Robert McQueen's engine shop

was still operating in New York in 1832, but its size was eclipsed by that of

Paul A. Sabbaton. By 1810 the latter had been given "general

superintendence of the late Mr. John Youle's foundry establishment" in New

York City where, as he later remarked, he had witnessed the "continual

exertions" of Robert Fulton to "obtain workmen who understood to work

from drawings." From his early experience during the heroic period of

steam engineering in America, Sabbaton went on to found his own extensive

engine‑building firm, and by 1838 his engines were operating in mills

from New England to the Gulf States.13

Other prominent New York

firms at mid-century included the Archimedes Works, started in 1833, and Hogg

and Delamater's Iron Foundry, begun in 1835. The former, which operated at two

sites in the city, employed 220 workmen and manufactured annually $235,000

worth of engines, sugar mills, dredging machines (of "improved" design),

and "iron vessels of various descriptions."14 Hogg and

Delamater's foundry employed 150 workers and produced each year $250,000 worth

of engines and other machinery. By 1853

these firms had been joined by the Morgan Iron Works and by Guyon, Boardman,

and Company. Guyon had been a leading engineer with the Morgan firm before

building his own works, which were housed at the foot of Eighth Street in a

building 200 by nearly 100 feet and three stories high. This establishment,

exclusively for the manufacture of steam engines,15 contained a

brass foundry, machine shop, blacksmith's shop, and storage space. By 1855 a

total of 3,130 men were employed in seventeen engine‑building firms in

the city, and the largest of them was the Novelty Works.16

During the late 1820s Dr.

Eliphalet Nott, president of Union College at Schenectady and an indefatigable

inventor, had begun work on an ill-fated steamboat named Novelty because the arrangement of its machinery was a

novelty. In this work he enjoyed the aid of Hezekiah Bliss—friend of

Fulton, partner of Daniel French, and steamboat builder and captain on his own

account.17 The engine for the experimental vessel was built at a

foundry on the East River in New York City. The foundry later was named the Novelty

Works after Nott's boat and was supervised by Bliss for some years. The works

continued to operate until the wearing out of the machinery and the sharply

rising land prices in the area led to abandonment of the site in 1870.

The

Novelty Iron Works, circa 1840, located at the foot of 12th Street and the East

River, New York City. To the left are the boiler shop, smith shop, and machine

shop. At the rear is the iron foundry, and at the right are the pattern house,

the paint shop, and two unidentified buildings.

1 Scientific American, volume 10 (16 June 1855), page 315.

2 John Fritz, Autobiography of John Fritz (New York, 1912), pages

32-33.

3 A. M'Elroy's Philadelphia Directory, for 1840 (Philadelphia,

1840), passim.

4 "John Roach," Appletons' Cyclopaedia of American Biography, volume 5, page 268.

5 Woodbury Report, page 156.

6 Joseph Harrison, Jr., The Locomotive Engine, and Philadelphia's

Share in Its Early Improvement (Revised edition, Philadelphia, 1872), pages

19-20.

7 Ibid., pages 30-3 1.

8 See sketch of Harrison in Dictionary of American Biography,

volume 8, pages 345-346; Harrison, Locomotive Engine, pages 56, 57.

9 Harrison, Locomotive Engine, page 60.

10 John H. White, Cincinnati Locomotive Builders, 1845-1868, U.S.

National Museum Bulletin 245 (Washington, 1965), page 8; Minus Ward, Remarks,

Propositions and Calculations, Relative to a Rail-Road and Locomotive Engines

to be Used upon the Same, from Baltimore to the Ohio River (Baltimore, April

1827), pp. v-vi; Thomas Richard Thomson, Check List of Publications on American

Railroads before 1841 (New York, 1942), page 69.

11 Sketch of Allaire in Dictionary of American Biography, volume

1, page 182; Brown, Allaire's Lost Empire, page 33; Morrison, Steam Navigation,

page 180.

12 Niles' Weekly Register, volume 40 (27 August1831), page 452;

Hunt's Merchants' Magazine, volume 16 (January 1847), page 93; Scientific

American, volume 9 (17 December 1853), page 110.

13 McLane Report, volume 2, page 115; Woodbury Report, passim;

Affidavit of Paul A. Sabbaton, 19 December 1838, in Heirs of Robert Fulton, 27

January 1846, House Document 145, 29th Congress, I session, page 17.

14 Hunt's Merchants' Magazine, volume 16 (January 1847), page 93

15 Scientific American, volume 9 (17 December 1853), page 110;

ibid., volume 8 (22 January 1853), page 149.

16 Hunt's Merchants' Magazine, volume 37 (September 1857), page

382.

17 Preble, Chronological History, pages 58-59. Bliss' account of

this story is given in "Resolution of Mr. Beekman on the Petition of

Levinus Vanderheyden, Neziah Bliss and Joseph D. Monnell," Documents of

the Senate of the State of New-York, Seventy-Sixth Session. 1853, Document 68,

volume 2 (Albany, 1853), pages 3-5.

Chapter

8

Developing

Engine Design

We

cannot have discoveries every few days,

like

those of the steam engine, the steamboat,

the

spinning jenny.... The progress

of discovery is a gradual one: the

trimming

off a superfluous shaft here, and

a

wheel, crank or drum there, produces

important

though not very striking results,

and

upon such improvements in the

aggregate

(and sometimes a very simple

one in the minutia of complex machines,)

depend the whole economics of the machinery‑its

profits and losses.

SCIENTIFIC American (1849)1

Even while they sought to

master the techniques and to provide for the needs of engine manufacture,

American steam engineers attempted to improve the product of their shops.

Although the typical stationary steam engine in this country at mid-century was

a considerably better product than its predecessor of fifty years before, it

was not radically different from, or better than, an English engine of the same

period. Improvement had gone on independently in the Old World and the New, but

there was constant communication between the two: engineers and publications

crossed the Atlantic in both directions and in increasing numbers. Added to

this was the fact that the inherent logic of the steam engine tended to limit

the potential number of improvements. The achievement of American engineers lay

not so much in surpassing their English counterparts—although in some

cases they did—but in succeeding in exploring and mastering an inherited

technology which was itself in a process of evolution.

As soon as the Watt

improvements were available in America, the old-type Newcomen engine was

immediately abandoned. When Oliver Evans patented and introduced his

high-pressure Columbian engine in 1804, the battle was joined between his

partisans and those of Watt's low-pressure, condensing system. James Watt had

considered the use of pressures above that of the atmosphere, but abandoned the

plan.

While still an apprentice in

the 1770s, Evans had witnessed the expansive power of steam but "formed no

idea of the means of its application, until he met with a description of an

atmospheric steam engine." He claimed to be "astonished to find that

the steam was not applied as the prime

mover, but only as the means to form a vacuum -- to apply the weight of the atmosphere. This he conceived to

be a great error."2 Drawing upon his rather inaccurate

knowledge of the history of the steam engine, Evans declared that "this

invention and discovery of Newcomen's, made from the hints given by doctor

Hooke . . . was the first step . . . from the simple path of nature! Here they

lost sight of the true principle discovered by the Marquis of Worcester."3

With a touch of bitterness, Evans confessed that "to philosophy we are

indebted for many of our most useful discoveries; yet," he continued,

"this single case should put our philosophy to the blush, and teach us,

however learned we may be, to listen with the closest attention, even to what

the most illiterate mechanician, who has taken the simple works of nature for

his guide, may say."4

Evans stopped short of

calling himself a babe and suckling, but the implication was clear: nature's

plan and true proportion had been betrayed into the toils of sophisticated, but

specious, reasoning. Evans, the simple American mechanic, had rediscovered the

true path of advancement. Benjamin Henry Latrobe, who was anything but a simple

mechanic, later claimed to have been asked by Evans why engines in England were

not built to use high steam. Latrobe replied by citing the abortive efforts of

Hornblower, Symington, and Murphy in this direction. He pointed out that these

engines "had been found to have so many inconveniences attached to

them" that each had been abandoned.5 Evans, however, sought

explanations, not precedents. Inveighing against "the mighty and infallible

opinions of Englishmen," he condemned

their belief that "no inventions, improvements, or original ideas, at

least possessed of merit, can spring from any other quarter of the world, than

the 'fast anchored isle'."6 Evans' feeling that science had

presided over the birth of the low-pressure engine but not that of his own has

been perpetuated by later writers.

When Evans introduced his

Columbian engine in 1804, it faced immediate and bitter opposition. Latrobe led

the opposition and never became reconciled to either Evans or his engine. He

based his position on the facts that the high‑pressure engine was too

sensitive to the pressure of steam in the boiler, thus moving "unequally

& precariously," and the danger of working with "the enormous

force of the Steam on the boiler." In contrast, he maintained, the Watt

engine worked with "no inconvenience or inequality" and was "as

safe as a clock."7 Ironically, Latrobe finally recommended the

use of high-pressure steam, but in engines not made on the Evans plan.

Evans always complained that

he was forced to watch his improvements exploited, even while their validity

was being denied. Latrobe was only the most obvious offender in this respect.

Daniel French, the early builder of western steamboats, expressed surprise in

1814 that Evans should pretend to any improvement in his use of high steam.

"For my part," he wrote, "I never save now heard of any Engine

but what used Steam more or less above the pressure of the atmosphere."8

In fact, French had already built at least one steamboat, equipped with a

"Seesaw" oscillating engine, "worked with high Steam without a

Condenser. with a double Circular boiler."9

Part of this opposition to Evans

and his claims was based upon a real reluctance to employ high-pressure steam

because of the great danger involved when raising steam in the crudely made

boilers of that time. Some of the resistance, however, was brought on by Evans'

claim to have patented the very use of high pressure, regardless of whether in

an engine of his design or not. When Thomas Copeland began to build engines in

Pittsburgh, "upon the principles of the celebrated WATT &

BOLTON," in 1813, he maintained "that he cannot be prevented from

using steam of any elastic force. It cannot be pretended," he concluded,

"that this is a new discovery."10 Evans, however, thought

differently. He made a clear distinction between his patented steam engines and

what he considered his patented principles, but continued to warn against the

unauthorized use of either.

Evans' steam-engine patent,

issued first in 1804, was extended by an act of Congress in 1815 and did not

expire until 1825. By the latter date, however, high-pressure steam was widely used

in steamboats on the western rivers and was almost universal among stationary

engines all over the country. Appearing before the Select Committee of the

House of Commons, on Steam Navigation, the American Consul at Liverpool

testified that in the United States, "all condensing engines are called

low‑pressure." Even these, he claimed, were sometimes worked at a

pressure of twenty pounds to the square inch.11 "An American low pressure engine

(so called)," it was said, "is very commonly of low pressure only by

courtesy." In 1834 an observer in Cincinnati, Ohio, counting sixty engines

operating in that town, noted that they were "all high pressure," and spoke for a whole section

when he added: "low pressure engines are not in good repute in the

west." By 1838 only a small number of low‑pressure engines were

listed as being at work in American mills.12

The second major development

in American steam engines during the first half of the nineteenth century was

acceptance of the principle that, for greater efficiency, steam should be used

expansively. Once again, Watt had already anticipated this development, having

used it as early as 1782, but it is not clear whether the first engines of his

design in America adopted this practice. Oliver Evans recommended that his

Columbian engines be driven by expansive steam, and in his handbook for

engineers he included a table "showing the proper time to shut off the

steam" on each stroke.13 Latrobe,

always ready to belittle Evans' work, commented that "Evans shuts it off,

to save his Engines from destruction, (as do all the high steam Engine makers

in England) and uses the expansive power alone & separately."14

It was Latrobe's opinion that

Francis B. Ogden, nephew of the famous Governor Aaron Ogden of New Jersey, was

the true inventor of the expansive use of steam.15 In 1811 Ogden,

with his uncle and Daniel Dod, had built a steamboat to operate between New

Jersey and New York. This same year he drew plans for an engine of two

cylinders working at right angles and using steam expansively; it was patented

in 1813. According to the specifications for this patent, Ogden planned to use

"two or more cylinders in such a manner as to form one engine, with the

view to cutting off the steam, of whatever pressure, at 1/4, 1/3, or 1/2 the

stroke of the piston, and using it expansively for the residue."16

Whether Ogden's engines were

directly responsible for the acceptance of expansive steam in this country is

perhaps a moot point. Latrobe built an engine in 1815, on Ogden's plan, for a

woolen mill in Steubenville, Ohio. He called this engine "the most

powerful Machine I have ever seen," and suggested to Ogden that it be

worked "with high steam without an air pump."17 The following year, Ogden

placed one of his engines in a steamboat operating on the James River in

Virginia, and in 1816 he made a journey to England where he met the venerable

Watt. When asked to comment on the novelty of Ogden's engine, Watt answered

that although the arrangement of the cylinders was new, "the expansive power

of steam has been long used in Cornwall, where much larger engines are erected

than are at first required: of course, they are not put to their full work; 1/4

or 1/3 of the power being sufficient, the cylinders are only thus far filled

with steam, and the residue of the stroke is made by expansion."18

It has been reported that

Ogden's patent was freely infringed on the western rivers, and that Murray and

Company, of Leeds, England, after making an engine under Ogden's direction,

used the patterns to produce others for the American market.19 It may be assumed,

therefore, that Ogden's principles were fairly widely known by the 1820s. Even

so, it seems likely that, since the high-pressure engine became the common type

for stationary purposes, it was more through Evans than Ogden that the use of

expansive steam became widespread. At any rate, it was said in 1854 that

"almost every engine is now so worked."20

A third area of improvement

in American steam engines was the positioning of the cylinders. At the

beginning of the century all engines used vertical cylinders with beams. By

mid-century the cylinder was usually placed horizontally. John Fitch was the

first American inventor to attempt to build an engine with a horizontal

cylinder, planning to place one in his steamboat of 1786. When he informed

Josiah Hornblower of this intention, the latter warned against it. Fitch had

conceived that plan "for the following reasons, to prevent its being too

top heavy, and that the jars that the Vessel would receive from the seas would

not be so likely to effect the Works."21 Hornblower responded

with the warning that "the horizontal position of the cylinder may be

proper for the reasons you mention, and also for the more convenient

application of the power, yet I fear it will be apt to make a leaky

Piston."22 Whether convinced by these arguments or others,

Fitch had abandoned the use of a horizontal cylinder by the time he built his

second boat in 1788.

The horizontal placement of a

steam cylinder permitted a direct linkage between the piston rod and an

eccentric arm connected to the flywheel. This seemed the best method of

avoiding the use of the bulky and expensive beam that was common to the Watt

and the Newcomen engines. Within the limited space of an industrial establishment,

such an arrangement was clearly to be desired, but for many years it was

retarded by a fear that the weight of the piston would cause excessive wear

along the bottom length of the cylinder. The horizontal cylinder was little

used in England before 1825 and perhaps became more common in the United States

at about the same time. By 1838 the distribution of engines in Philadelphia

County showed 2 rotary engines, 13 oscillating engines, 57 with upright

cylinders, and 107 using horizontal cylinders.23

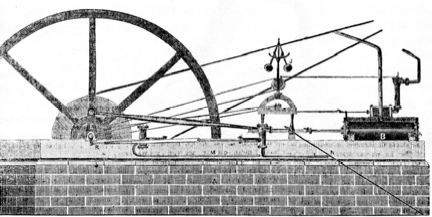

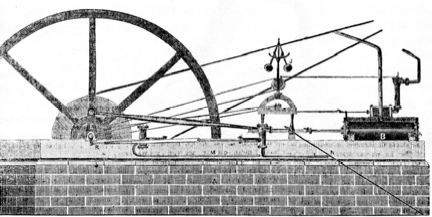

A typical horizontal steam engine, 1848. From Scientific

American, Volume 4 (4 November 1848),

page 54.

By 1852 it was said that

"the favorite construction for land engines throughout the United States is

that in which the cylinder is placed horizontally on flat beds."24

It cannot be demonstrated that any one engine builder or inventor was

responsible for this universal acceptance. Fitch's attempt to use such an

arrangement was in no sense a precedent for later acceptance, but did show

early recognition of its desirability. It is likely that with improved

piston-packing and generally improved durability and accuracy of construction,

builders felt more free to experiment with horizontal engines.

The oscillating engine gained

considerable currency in America toward the middle of the nineteenth century.

It too had originated in England, where William Murdock had made a model of

such an engine while in the employ of Boulton and Watt. It was revived in 1827

by Henry Maudslay, but was used little for stationary engines in Great Britain.

The first American use of this type of engine was made by Daniel French on his

steamboats. Commenting on one of French's boats in 1812, Latrobe noted that

"the horizontal Cylinder has been very often used, tho' not made to

vibrate." He went on to praise French as "a man of very uncommon

talents, both as to the conception & execution of anything to which

mechanical power can be applied," but insisted that "the immediate application

of the Piston to the Crank of the wheel which is rendered practicable by the

vibratory motion of the cylinder is not more simple than the application of Shacklebars . . . from the

cross of the Piston to the Crank."25

French continued to build engines

in the West, and by 1830 Stacy Costell was building "vibratory"

engines in Philadelphia. N. Rowland, also of Philadelphia, patented such an

engine in 1833 and built at least one in that city. The Novelty Works of New

York was building oscillating engines by 1833. In 1848 the statement was made

that this type "is coming into general use in England, and a few have been

erected here. It is then an object of some interest to our mechanics."26

The pace of their acceptance accelerated during the 1850s, and by 1855 it could

be said that "oscillating engines are very simple and compact, and are

fast extending in use. We believe they have not yet been applied to

locomotives," it was noted, "but they have to all other purposes."27

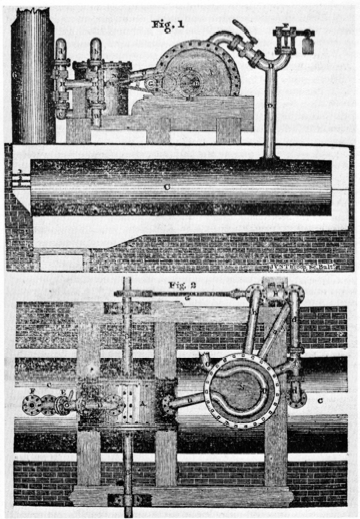

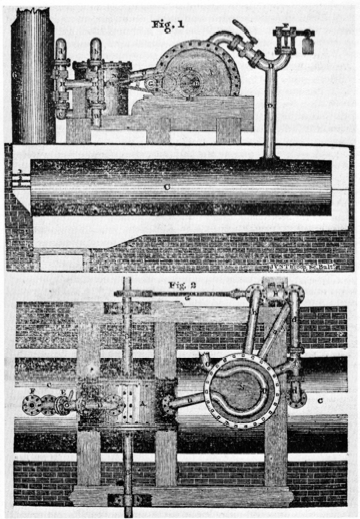

Oscillating steam engine of Ebenezer A. Lester, 1827.

Restored patent drawing in records of the patent office, National Archives,

Washington, D.C.

The chief advantage, as well

as the major disadvantage, of the oscillating engine was that the motion of the

cylinder regulated the flow of steam to the piston. It was explained in 1852

that the "oscillating cylinder is much employed for small land engines, as

it affords a cheap substitute for the slide valve, if formed in the usual

manner, by which one of the gudgeons or trunnions is made to regulate the

entrance and exit of the steam, while the other gudgeon or trunnion can be

employed to work the feed‑pump."28 The principal difficulty was that in order to prevent

the escape of steam, the trunnions were fitted very tight, thus increasing

friction which cut the power of the engine and caused undue wear on the

trunnions themselves. Here too, a general improvement in strength and accuracy

of construction helped to alleviate this problem.

The history of compound

cylinder engines in this country is similar to that of other innovations. The

engines were conceived in England, then either brought to America, or conceived

independently in this country at an early date. After a period of uncertain

success, they reached a fairly high level of development and use. Engines of

two cylinders were made in England by Jonathan Hornblower in 1781 and Arthur

Woolf in 1804. Their earliest use in the United States was in 1813, when

Francis B. Ogden patented his compound engine. Using steam expansively, this engine

was to work two pistons simultaneously at right angles to each other. It was

explained that "one is at its maximum when the other is at its minimum, so

that there is no necessity for a balance wheel as a reservoir of power: for

when one piston ceases momentarily to act, the other instantaneously continues

the motion in the same direction." It was pointed out that "there is

nothing new in two cylinders, or in working by expansive steam, but the getting

rid of the balance wheel by the simultaneous action of each piston in the

manner above described . . . is new."29

Actually, Ogden's twin‑cylinder

engine was not of the classic compound type, developed by Woolf, since both

cylinders were to use steam of the same pressure. In the true compound engine,

the steam was introduced into the first cylinder under high pressure and then

allowed to expand into the second cylinder under a lower pressure. This type

seems not to have been used to any extent in America until the 1840s. Despite

scattered reports of experiments with compound engines, it was estimated in

1856 that "this class of engine has received but partial trial in our

country."30

The

use of high-pressure steam expansively and the new positioning of cylinders

were major innovations, but they do not account for the greatest part of the

improvement of the steam engines in America. They were accompanied by an almost

constant tinkering with the details of engine design: piston packing valve

action, governing, and linkage were the problems receiving particular attention

31 Not all of this activity, of course, was productive of any real

benefit to steam technology. Contemporary and recent literature are replete

with references to the fact that the period following Watt's active work was

one of attempting to absorb and convert his inventive genius into useful

innovation.

A remark was made in 1819

that "on the expiration of Mr. Watt's patent, many ingenious mechanics

attempted to improve the structure of the machine, and the records of the

[British] patent office contain more upon this subject, than any other."

As a result, "scarcely two following engines were made alike for many

years, until, by the results of a vast deal of invention and experience, those

methods . . . became settled into established forms; but none of them are

superior to the original of Mr. Watt's."32 Robert H. Thurston, a leading engineer, looking back

over most of the nineteenth century, spoke of the period after 1850 as the

"Period of Refinement" and said that "the inventor has been

superseded by the engineer."33 In other words, by mid-century

the inventors had explored all the various alternatives inherent in the Watt

engine after that, improvement tended to be the province of the engineer with

scientific training.

Because of the different

needs of American engineers and the time lag in the exchange of technological

information between this country and Great Britain, the major variations on

Watt's basic engine design were not all adopted and perfected in the United

States until about 1830. For example, it was not until 1827 that the basic and

useful table "On the relative proportions of the various parts of the

Boulton and Watt's, or low pressure, Steam Engine" was published in this

country. This table, which showed "the very important results of the

experience of Boulton and Watt, in proportioning the most essential parts of

their steam engines," was said to have existed in manuscript form in all

English engine shops. A copy was "procured, by an American engineer,"

who had recently visited England.34

After 1830, suggested

improvements tended to be either repetitious, bizarre, or dealt with minor

details of arrangement and construction. The best evidence of this leveling off

of real improvement is the clear and dramatic rise in the number of attempts to

perfect the rotary steam engine. This piece of mechanism, which absorbed so

much inventive talent during the second quarter of the nineteenth century in

America, had, like most other developments in steam engineering, been

investigated by Watt in the eighteenth century. In this country, Oliver Evans

had toyed with a rotary engine during the 1780s, but abandoned it for his high‑pressure

Columbian engine.

One early American rotary

engine was built in Baltimore in 1819 by George Stiles, a former mayor of that

city, and his son John S. Stiles. Three years before, Hezekiah Niles, ever

ready to praise and encourage American ingenuity, announced with pride that a

Mr. Curtis of Massachusetts had achieved "a desideratum in steam engine, a

complete rotary motion without a fly wheel or balance, an object of long and

arduous research in Europe, of the greatest advantage to the mechanical

world." The engine was reportedly "composed only of a cylinder

containing a shaft‑wheel with valves" and was touted as "vastly

superior to those of Watt and Bolton, Evans, or any subsequent

constructor" Curtis had one of his engines operating the sawmill of A. and

N. Brown of Manhattan Island and had "after encountering a long series of

difficulties . . . established a manufactory in Baltimore."35

Rotary steam engine of George and John S, Stiles, 1819.

From Niles Weekly Register, Vol 17 (October 16, 1819), p 114.

The Stiles, father and son,

were associated with Curtis in his Baltimore venture. A stationary engine used by

the Stiles had been set at boring cannon during the War of 1812, then was used

for ordinary shop work, and was finally used to operate a gristmill. After five

years it was said to be "still working with equal power, without having

received any material repairs." The four virtues claimed for it were its

lightness, compactness, cheapness, and simplicity of motion. The last point was

clinched, in Niles' mind, by the fact that the one then "working at Mr.

Stiles' factory and mill is under the care of a black man, whose chief

qualities, as needful to its management, are sobriety, and attention."

Stiles, besides carrying on other types of work, made these rotary engines for

general sale. Not untypically, in 1817 they even placed one of their engines

aboard the boat Surprise, a steamboat

which was said to be quite fast.36

Early in the nineteenth

century there were sporadic reports of American mechanics, such as Stiles,

having finally perfected a rotary engine, but it is significant that of the 123

patents issued in this country for rotary engines before 1860, only 20 were

dated through 1830, while the remaining 103 were issued between 1831 and 1859.

Plainly, interest increased rather than waned.37

The idea of the rotary engine

was at least as old as the steam wheel of Hero of Alexandria, and apparently

every inventor from the time of Watt had been struck with the notion that an

engine which produced a rotary motion initially would be far superior to one in

which the reciprocating motion had to be converted to circular. As late as 1829

such arbiters of American mechanical progress as Zachariah Allen were

denouncing "the great loss of power resulting from the reciprocating

movement of the piston of the common steam engines" and calling for an

engine which would "apply the steam directly to turn a wheel, as water is

applied to turn a water wheel, in order to produce at once a continued circular

motion without the intervention of the beam, crank, and fly wheel."38

But apparently a current of informed opinion was already flowing the other way.

Remarking that "it may seem hardy to question a dogma, which has remained

so long unquestioned," an inventor in 1822 endeavored to "show,

contrary to the received theory, that there is no loss of power in the reciprocating

movement of the common steam‑engine."39

From the beginning of their

publication, the Franklin Journal and

the Scientific American launched

vigorous campaigns against rotary engines. The editor of the former claimed to

"have support of many practical engineers" for his opinion that

"projectors are generally mistaken, respecting the loss of power, which

they think, takes place in the crank."40 The editor of the Scientific

American hedged a bit by conceding that a

successful rotary engine was theoretically possible, but pointed out that

already, "the Mechanical ingenuity that has been expended in the invention

and improvement of rotary engines, perhaps exceeds that of all other

machines."41 Between September 1848 and June 1849 he published

a history of attempts to build such an engine (all abortive), with the avowed

object "to throw light upon the subject, in order to stop many men of real

original mechanical genius from wasting their time."42 The

editor claimed to have "seen no less than 60 representatives of different

rotary engines" and blamed this continued activity on a "want of

correct understanding of the principles of the steam engine."43

The editor of still another technical journal professed to see "a perfect

mania" for rotary engines in 1847.44

The Franklin Institute of

Philadelphia had earlier been concerned with this same problem, remarking that

"the great number of proposed improvements in the steam engine, equally

manifest the possession of ingenuity, and the deficiency of knowledge and experience,

in their projectors." To help remedy this tactfully described situation,

the Institute appointed a committee on inventions to review and advise on

improvements, offering its services gratis and promising to maintain "the

utmost secrecy."45 The persistence of interest in the rotary

engine, however, cannot be explained solely on the basis of ignorance. The fact

was that the common steam engine, as inherited from Watt and modified by Evans

and others, appeared to inventors to have reached the practical limits of its

perfection, and further major improvement was sought through a new departure.

Despite all counsel, efforts

to develop the rotary engine continued. One persistent inventor was James A.

Stewart of Cross Plains, Tennessee, who patented his rotary engine in 1841 and

the following year had the firm of R. M. Roe and Company of New York City build

a prototype. This engine was used for a short time in their shops, and Stewart

was encouraged enough that he continued to try to perfect its details. About

1848 he made an engine of adequate power to operate a sawmill a few miles north

of Nashville. The success of this engine led him to travel to St. Louis where

the Eagle Foundry of Clark, Renfrew and Company manufactured these engines for

general sale. The design of his engine was simple. Two cog wheels of long axis

were enclosed in a tight-fitting iron jacket. Steam was introduced

perpendicularly to the axes of the two wheels—the only moving

parts—and along the line where they meshed. Except for Babbitt metal

lining of the pillow blocks which carried the wheels,46 the engine

was built of iron throughout.

Despite persistent claims

over a period of five years by Stewart and by his supporters that his engine

had at last been perfected, it never was. Finally in 1853 he decided, as he

said, "to abandon any further attempts to introduce my plan of rotary

engine." He was prepared to admit that "an attempt to excel,

materially, the reciprocating engine, in point of economy, by substituting a

rotary, is chimerical." He persisted, nevertheless, in his belief that his

principles were sound even though they failed in practice. The major faults of

his engine were "its liability to derangement by expansion and contraction

of metal, and the yielding or displacement of adjusting screws employed in

maintaining the steam wheels in their proper position." Discouraged,

Stewart moved to Texas and entered the business of flour milling.47

The efforts to build a better

rotary engine, like most attempts to improve the steam engine, were guided by

the supposed imperatives inherent within the engine itself. At least one major

improvement in America, however, was imposed by philosophical and economic,

rather than mechanical, desiderata. It was noted in 1857 that "within the

last few years the attention of ingenious men in [Philadelphia] ..., as well as

in other places, has been directed largely to simplifying the Steam Engine,

removing all essentially unnecessary parts, cheapening its price, and

diminishing its size."48 A part of this was merely the endless

and undramatic battle to keep a piece of mechanism, once perfected, from being

corrupted by innovation. The major incentive behind this activity, however, was

the search for a smaller engine—perhaps even portable.

Rotary steam engine of James A. Stewart, 1850. For Scientific

American, Vol. 6, (Nov. 9, 1850), p.

157.

Thomas Jefferson had called

for such engines as early as 1815. A small steam engine, he wrote,

"applicable to our daily concerns, is infinitely more valuable than the greatest

which can be used only for great objects." The former President was caught

in the seeming contradiction between his enthusiasm for

"improvement," and his revulsion at the idea of great industrial

centers, based on steam-powered factories, springing up in America as they

already had in England. His vision of small portable engines resolved the

conflict, and he contemplated with satisfaction the idea that a small engine

might be developed that would "raise from an adjacent well the water necessary

for daily use; to wash the linen, knead the bread, beat the homony, churn the

butter, turn the spit, and do all other household offices which require only a

regular mechanical motion."49 Thus the instrument of industrial

vice in Europe would become the handmaiden of domestic virtue in America.

Jefferson was not alone in

his hope that the steam engine might be domesticated, made democratic, and

applied to the benefit of the common man. Hezekiah Niles quoted Oliver Evans to

the effect that "the time would come when the powers of steam should be so

well ascertained and so simply applied, that the very old women would do the

common business of housewifery with it."50 It was Evans'

opinion, again according to Niles, that "the time would come, when, every

person able to build a house costing 10,000 dollars, would provide himself with

a steam engine, as a part of its furniture, to wash the clothes, scrub the

floors, etc. etc."51

Writing in celebration of the

national centennial in 1876, Abram Hewitt, a worthy representative of

post-Civil War American civilization, announced that "If I were asked what

elements had most to do with the swift progress of our country, I should

answer, freedom and the steam engine. But deeper even than any organized declarations

of outward forms of freedom lies the influence of the steam engine, which has

been from the day of its birth, in spite of laws and dynasties, and all

accidents of history, the great emancipator of man."52 Beneath

the thoroughly Victorian optimism and bravado of placing the steam engine above

the Declaration of Independence and, presumably, above even the martyred

Abraham Lincoln, that other "great emancipator of man," lay the

intuitive realization, only recently rediscovered, that the unique contribution

of American civilization to world progress lay in its standard of living for

the common man.

It is not to be expected that

the engine-maker, laboring to pare a few pounds or a troublesome lever from his

steam engine, thought in terms of the message of America. But the very fact

that this urge toward smaller and simpler engines was eminently practical was

indicative of the thoroughness with which the concept of the mass market had

already permeated the thinking of American industry. The Scientific American in 1853 stated that the want of a small

portable engine is seriously felt by the public.

The farmer wants them to

thresh his grain and cut his straw, to saw his wood, and as soon as they are

properly constructed to draw his plow. The mechanic wants them for the various

operations of his workshop, the manufacturer in a small way wants those that

require but little room, and can be easily moved about as he may change his

residence, and we may hope to see the day when they will be made so cheap that it

will become almost a necessity of the household. The world is growing wiser and

lazier every day.53

The advent of the internal

combustion engine and the electric transmission of power removed some of the

urgency from this quest, but during the first half of the nineteenth century,

the attempt to provide a truly portable steam engine was a constant and

important activity.

From the vantage point of his

annual report for the year 1843, the Commissioner of Patents H. L. Ellsworth

observed that "the great progress made in the steam-engine since Watt's

time is more due to the increased knowledge of its properties, and better

understanding of the general rules that should govern mechanical structures,

and the improvement of all the mechanic arts, particularly in the working of

iron, than to the improvements in the engine itself; although these are, by no

means, insignificant."54 This progress must be credited largely

to the men who manufactured steam engines, aided by what one writer in

Silliman's American Journal of Science referred

to as "the patronage and encouragement of the public, and the auxiliary

efforts of the Engineer and the Philosopher."55

The patronage and

encouragement of the public is sufficiently documented by the wide and

enthusiastic acceptance of steam power which characterized these years.

Similarly, the multiplication and gradual professionalization of steam

engineers need not be labored. Thomas Cooper, noting the activities of Robert

Fulton, Oliver Evans, Benjamin Henry Latrobe, and others, wrote in 1814 that

"so much exertion, and by such men, affords ground to hope that at no

distant time, improvements may take place, that will put our Engineers of

America, upon a par at least with those of England." The "three great

requisites of a civil engineer," he declared, "are first a profound

knowledge of mathematics, and an habitual facility of applying mathematical

principles and calculations to mechanics and machinery. Secondly, a full

knowledge of the modern science of chemistry. Thirdly, an habitual facility in

drawing and designing with neatness and accuracy. To these should be added,

actual observation and study of the principal machines in use and their

application."56 This ambitious prospectus remained desirable,

rather than actual, for many years, despite suggestions that the federal

government set up an academy to train steam engineers. The first engineers in

this country were either self‑tutored or trained in England, and

frequently they were also manufacturers. Latrobe was one of the first and most

successful among those who attempted to earn a living by the merit of his

engineering and entrepreneurial talents alone.

Oliver Evans was a prime

example of the inventor-manufacturer-engineer, who contributed so much to the

early progress of steam engines in this country. Quoting the old saw that

"truth lies in a well," Evans described the "most intense

study" that preceded his new mechanisms. "After having a faint

glimpse of the principle," he said, "it was with many toilsome and tedious

steps that I attained a clear and distinct view. I received great assistance

from the result of experiments made by others, which are to be found in

scientific works."57 He consulted the tables of John Dalton and

speculated on the possibility of discovering a caloric-proof substance out of

which boilers might be made.58 So valuable did Evans find the

available scientific works, that he suggested in order "to aid the

progress of improvement in the arts and sciences," the federal

government might, "at the expense of the community, employ ingenious

persons, in every art and science, to make with care every experiment that

might possibly lead to the extension of our knowledge of principles."59 He specifically singled out

investigations of solar radiation, presumably to raise steam in boilers, as an

area in which the ''expense of such investigations cannot, in many instances,

be borne by those who have the mental powers to design." In such cases he

thought "aid from government becomes necessary.” 60

Evans' views on the support

of basic scientific research by the federal government were advanced, though

shared by such important public figures as Thomas Jefferson and John Quincy

Adams. In actual practice, engineers and manufacturers were forced to make use

of what bits of scientific fact and encouragement they could find. They can be

said to have been denied this resource only if the term science is limited in

this case to a fully mature understanding of thermodynamics.61 Even

within this narrow definition, many early American scientists notably Joseph

Henry, Thomas Cooper, and James Renwick—concerned themselves with the

theory and economy of steam. George Corliss, for example, was said to have had

direct assistance in the invention of his Corliss engine from a professor of

mathematics and natural philosophy at Brown University.62

It is probably a mistake,

however, to so limit the definition of scientific aid to steam engineering.

Manufacturers and projectors made constant recourse to whatever mathematical

abilities they might have possessed. Furthermore, they sought the approval and

endorsement of notable scientists for their improvements in engines. Such

approbation was eagerly sought and widely advertised when received. Finally,

they shared a common expectation that science would prove useful to the arts.

There was near universal agreement with Alonzo Potter when he wrote that

"on the one hand, science has furnished principles for the arts to apply:

on the other, the arts have proposed problems for science to resolve; and this

mutual aid and dependence have been the means of carrying both forward, at a

rate continually accelerated."62 It was admittedly a statement

of faith—but, no doubt, it was a faith that sustained.

At the end of the American

Revolution, the Watt steam engine presented American mechanics with a major and

complex problem in technological assimilation. Faced with the staggering task

of first learning to make and then to apply these engines, interested Americans

made use of whatever English guidance was available through books and emigrant

mechanics. Despite the handicap of having to work without a firm theoretical

basis, these improvers applied to their task all the mathematics, experimental

data, and knowledge of thermodynamics they could muster. In general, the first

half of the nineteenth century was a period marked by consolidation and

improvement rather than by dramatic breakthroughs in the technology of steam.

Experiments had been tried

with several types of engines. Those best suited to steamboats, locomotives,

and the various stationary purposes had become more or less standardized by

mid-century. Improved design, more sturdy construction, and improved economy

had also contributed to making steam power a widely accepted motive force. Simultaneously,

a growing demand for engines had stimulated these same improvements so that

steam technology had moved forward on a broad and connected front. Salients of

more rapid development occurred, as in the case of the use of high‑pressure

steam, and in a few instances indifference or hostility brought lags in other

areas. But on the whole, the advance was rapid and complete. Starting in the

urban centers of the Middle Atlantic States, the new technology spread into the

West, the South, and finally to New England. By mid-century the revolution was

complete.

1 Scientific American, volume

4 (5 May 1849), page 261.

2 Evans, "Account," Archives of Useful Knowledge, volume 2 (1812), page 366; Evans, Abortion,

pages 95-96.

3 Evans, Abortion, p. 90n.

4 Ibid., page 3.

5 B. H. Latrobe to

Charles T. Ingersoll, 17 January 1814, B. H. Latrobe MS. Coll., MHS.

6 [Evans] Elisha, Patent Right Oppression Exposed, pages 63-64.

7 B. H. Latrobe to Andrew

Hazelhurst, 19 October 1810, B. H. Latrobe MS. Coll., MHS.

8 Daniel French to William Thornton, 12 February 1814, William

Thornton papers, volume 4, LC.

9 B. H. Latrobe to Robert Fulton, I March 1814, B. H. Latrobe MS.

Coll., MHS.

10 Pittsburgh Gazette, 9 April 1813.

11 "'Report of the Select Committee of the House of Commons,

on Steam Navigation to India; with the Minutes of Evidence, Appendix, and

Index. 1834," Edinburgh Review, volume

60 (January 1835), page 475n. This confirmed the statement of Frederick Graff,

made in 1817, that Boulton and Watt engines were commonly worked from 10 to 20

psi. Frederick Graff to Robert Vaux, 9 July 1817, in Communications.

. . on the Explosions of Steam Boilers, page

8.

12 American Railroad Journal, volume 3 (27 December 1834), pages 806-807; Woodbury Report, passim.

13 Evans, Abortion, pages

28‑30.

14 B. H. Latrobe to Thomas Cooper, 2 April 1814, B. H. Latrobe

MS. Coll., MHS.

15 Ibid.

16 "Who First," American Repertory, volume 4 (1841), page 172.

17 B. H. Latrobe to N. l.

Roosevelt, I August 1815, B. H. Latrobe

MS. Coll., MHS; B. H. Latrobe to

F. B. Ogden, 23 January 1815, B.

H. Latrobe MS. Coll., MHS.

18 Quoted in "Who First," American Repertory, volume 4 (1841), page 172.

19 Ibid., page 173.

20 Scientific

American, volume 10 (4 November 1854), page

61.

21 John Fitch to Josiah Hornblower and Christopher Colles, 17 May

1786, Fitch papers, volume 1, LC.

22 Josiah Hornblower to John Fitch, 24 May 1786, Fitch papers,

volume 1, LC.

23 Woodbury Report, page 156

24 Scientific American, volume

8 (18 December 1852), page 107. Seth Boyden is credited with developing

"the cast‑iron prome

or bed." Appletons' Cyclopaedia of American Biography, volume 1, page 341.

25 B. H. Latrobe to William Cooper, 14 October 1812, B. H.

Latrobe MS. Coll., MHS.

26 Scientific American, volume

3 (13 May 1848), page 265.

27 Ibid., volume 10 (24 March 1855), page 218.

28 Ibid., volume 8 (18

December 1852), page 107.

29 [ Cooper ], "Account," Emporium of Arts and

Sciences, volume 2 (1814), pages 473-474.

J. Dowers, Jr., of Pittsburgh and Philadelphia, disputed some of the points of

Ogden's patent. See B. H. Latrobe to Thomas Cooper, 2 April 1814, B. H. Latrobe

MS. Coll., MHS. A Mr. Rodman of South Carolina, also planned a low-pressure, twin-cylinder

engine in 1814. [Cooper], "Account," Emporium of Arts and

Sciences, volume 2 (1814), page 373.

30 Scientific American, volume

3 (13 May 1848), page 268; ibid., volume 11 (5 January 1856), page 129.

31 The most famous and successful American innovation in the field

during the middle years of the century was the valve gear of George Corliss.

His impact was made in the period following that covered here, but something of

his background will be found in Robert S. Holding,"George H. Corliss of

Providence, Inventor," Rhode Island History, volume 5 (January 1946), pages 1-17.

32 Cyclopaedia; or, Universal Dictionary, volume 34. For recent attempts to explain this in

terms of ''plateaus of technology," see Mumford, Art and

Technics, page 84, and Milton Kerker,

"Science and the Steam Engine," Technology and Culture, volume 2 (Fall, 1960), pages 385,387.

33 Thurston, Growth of the SteamEngine, pages 304, 305. I would suggest that this period

began about two decades earlier.

34 Franklin Journal, volume

3 (May 1827), pages 336-339.

3 5 Niles' Weekly Register, volume

10 (I June 1816), page 219. Also on Curtis' engine see memo in hand of Nathan

Read, 24 May 1816, and Bailey L. Pinsset [?] to William P. Page, 23 December

1816, Nathan Read papers, volumes 4 and 1, Essex Institute, Salem,

Massachusetts.

36 Niles' Weekly Register, volume

17 (16 October 1819), pages 97‑98.

37 Index of Patents, volume

3, pages 1219-1223. It should be

noted that because of the quixotic nomenclature of the Index, one can never be sure of having counted all patents

of any given type.

38 Allen, Science of Mechanics, page 329.

39 Minus Ward, "Ward's Alternating Steam-Engine," American Journal of Science,

volume 4, no. I (1822), page 91. See also

A. B. Quinby, "On Crank Motion," ibid., volume 7, no. 2 (1824), pages

316-323, and A. B. Quinby,

"On Crank Motion, in reply to the remarks of the author of a Review in the

North American," ibid., volume 9, no. 2 (1825), pages 317-324.

40 Franklin Journal, volume

2 (December 1826), page 282.

41 Scientific American, volume 2 (12 June 1847), page

301.

42 Ibid., volume 4 (30 June 1849), page 325.

43 Ibid., volume 3 (19

August 1848), page 380.

44 Eureka, volume 2

(November 1847), page 44.

45 Franklin Journal, volume

2 (September 1826), page 187.

46 Niles' Weekly Register, volume

63 (19 November 1842), page 184; Scientific American, volume 3 (26 August 1848), page 390; ibid., volume 5

(27 July 1850), page 356; ibid., volume 6 (26 October 1850), page 43; ibid.,

volume 6 (16 November 1850), page 68; ibid., volume 8 (2 October 1852), page

21.

47 Scientific American, volume

8 (2 April 1853), page 227.

48 Freedley, Philadelphia and its Manufactures, page 316.

49 Thomas Jefferson to George Fleming, 29 December 1815, in Writings

of Thomas Jefferson (Washington), volume 6,

page 505. Also see Edwin T. Martin, Thomas Jefferson: Scientist (New York, 1961), pages 72‑73.

50 Undated addenda to Niles' Weekly Register, volume 3 (September 1812 - March 1813), page I. It may be said that

the vision of Jefferson and Evans has been fulfilled, in the sense that as late

as 1945, two-thirds of the electricity

in the United States was produced by steam power. Bureau of the Census, Historical

Statistics, page 156. Cf. Mumford, Art

and Technics, page 78.

51 Niles' Weekly Register, volume

50 (16 April 1836), page 113.

52 Abram S. Hewitt, "A Century of Mining and Metallurgy in

the United States," Transactions of the American Institute of Mining

Engineers, volume 5 (1876-1877), page 174.

53 Scientific American, volume

9 (3 December 1853), page 89.

54 Report of the Commissioner of Patents, For the year 1843, House Document 177, 28th Congress, Ist session, page

273.

55 Quinby, "On Crank Motion," American Journal of

Science, volume 9 (1825), pages 322-323.

56 [Cooper], "Account," Emporium of Arts and

Sciences, volume 2 (1814), pages 374, 385.

57 Evans, Abortion, p. 139.

58 [ Evans ], Oliver Evans to His Counsel, page 41; Evans, Abortion, page 134.

59 Evans, Abortion, page 139.

60 Ibid., page 43.

61 I have found, for example, no American references to the work

of Sadi Carnot before the Civil War. The argument for scientific aid to the

development of the steam engine during the 17th and 18th centuries is ably made

in Milton Kerker, "Science and the Steam Engine," Technology and

Culture, volume 2 (Fall, 1960), pages 381‑390.

62 Robert S. Holding, "George H. Corliss of Providence,

Inventor," Rhode Island History, volume

5 (January 1946), page 7.

63 Alonzo Potter, The Principles of Science A pplied to the

Domestic and Mechanic Arts, and to Manufactures and Agriculture . . . (Boston,

1841), pages 266‑267.

Bibliography

Unpublished

Manuscripts

Baker Library,

Harvard University Graduate School of Business Administration, Cambridge,

Massachusetts

Samuel Slater collection

Essex

Institute, Salem, Massachusetts

Nathan Read papers

The Filson

Club, Louisville, Kentucky

Various collections

Franklin

Institute, Philadelphia, Pennsylvania

Oliver Evans papers

Library of

Congress, Washington, D.C.

Isaac Briggs papers

John Fitch papers

William Thornton papers

Maryland

Historical Society, Baltimore, Maryland

National

Archives, Washington, D.C.

Boulton

correspondence, record group 104, records of the Bureau of the Mint

Census

of manufactures, schedules of the, record group 29, records of the Bureau of

the Census

Patent

drawings, restored, record group 241, records of the Patent Office

State,

miscellaneous letters of the Department of, record group 59, records of the

Department of State

New York

Historical Society, New York, New York, Robert Fulton papers New York Public

Library, New York, New York

Robert Fulton

papers, Montague collection

Pennsylvania,

Historical Society of, Philadelphia, Pennsylvania

Various collections

Washington,

University of, Seattle, Washington

Manning

Ferguson Force, papers collected by Peter Force re John Fitch, manuscript

collection

Periodicals

American Institute

of Mining Engineers, Transactions, 72 volumes, 1871‑1925.

The American

Journal of Improvements in the Useful Arts, and Mirror of the Patent Office in

the United States (Washington,

D.C.), I volume, 1828.

The

American Journal of Science and Arts, 80 volumes, 1818‑1860.

American

Mechanics' Magazine (New

York), 2 volumes, 1825‑1826.

The American

Repertory of Arts, Sciences, and Manufactures (New York), 4 volumes, 1840‑1842.

American

Society of Mechanical Engineers, Transactions, 48 volumes, 1880‑1926.

The American

Weekly Messenger; or, Register of State Papers, History and Politics. For 1813‑14

(Philadelphia), I

volume, 1814.

Archives of

Useful Knowledge (Philadelphia),3

volumes, l 810‑1813.

Emporium of

Arts and Sciences (Philadelphia), old series, 2 volumes' 1812‑1813, new series 3 volumes

1813‑1814

Eureka; or,

The Journal of the National/ Association of Inventors (New York), 2 volumes, 1847‑1848.

Hunt s

Merchants' Magazine and Commercial Review (New York), 58 volumes, 1839‑1868.

The Medical

Repository (New

York), 11 volumes, 1797‑1808.

The National

Magazine and Industrial Record (New York), 2 volumes, 1845‑1846.

Niles'

Weekly Register (Baltimore)

1811‑1849.

Quarterly

Journal of Agriculture, Mechanics, and Manufactures (New York), 1 volume, 1834.

The

Universal Asylum, and Columbian Magazine (Philadelphia), 9 volumes, 1787‑1792.

The Useful

Cabinet (Boston), I

volume, 1808.

Books and Articles

Adams, John. Diary

and Autobiography of John Adams, edited by L. H. Butterfield. 4 volumes, Cambridge, 1961.

A Digest of

Patents, Issued by the United States, from 1790 to January 1, 1839.... Washington, D.C., 1840.

Albion, Robert

Greenhalgh. The Rise of New York Port, 1815‑1860. New York, 1939.

Allen, Zachariah.

The Science of Mechanics, as applied to the Present Improvements in Europe,

and in the

“ “, United

States of America: Adapted as a Manual for Mechanics and Manufacturers. Providence, 1829.

“ “,An

Alphabetical List of All Patents and Patentees on Record in the Patent Office. Washington, D.C., 1830?

" “, An

Old Grasshopper Engine," Iron Age, volume 53 (25 January 1894), pages 151‑152.

Appletons'

Cyclopedia of American Biography, edited by James Grant Wilson and John Fiske. 6 volumes New

York, 1888‑1889.

Arndt, Karl J.

"Three Hungarian Travelers Visit Economy," Pennsylvania Magazine

of History and Biography, volume 79 (April 1955), pages 197‑216.

Ashton, T. S. The

Industrial Revolution, 1760‑1830. London, 1948.

“ “, Iron and

Steel in the Industrial Revolution. Manchester, 1924.

Babcock, George

H. "Substitutes for Steam," Transactions of the American Society

of Mechanical Engineers, volume 7 (1885‑1886), pages 680‑741.

Bancroft,

Joseph. Census of the City of Savannah, together with Statistics Relating to

the Trade, Commerce, Mechanical Arts... 2d edition, Savannah, 1848.

Bangs, Isaac.

"New York in 1776," Historical Magazine, volume 4, 2d series (December 1868),

pages 305‑306.

Batchelder,

Samuel. Introduction and Early Progress of the Cotton 31anufacture in the

United States. Boston,

1863.

Bathe,

Greville. A n Engineers's Miscellany. Philadelphia, 1938.

“ “ and

Dorothy Bathe. Jacob Perkins: His Inventions, His Times, and His

Contemporaries. Philadelphia,

1943.

“ “Oliver

Evans: A Chronicle of Early American Engineering. Philadelphia, 1935.

Bigelow, John

P., compiler. Statistical Tables. Exhibiting the Condition and Products of

Certain Branches of Industry in Massachusetts, for the Year Ending April 1,

1837 Boston, 1838.

Binder,

Frederick M. "Pennsylvania Coal and the Beginnings of American Steam

Navigation," Pennsylvania Magazine of History and Biography, volume 83 (October 1959), pages 420‑445.

Bining, Arthur

Cecil. Pennsylvania Iron Manufacture in the Eighteenth Century. Harrisburg, 1938.

"Biographical

Sketch of William Henry of Lancaster County, Pennsylvania," Pennsylvania

Magazine of History and Biography, volume 27 (1903), pages 91‑93.

Bishop, J.

Leander. A History of American Manufactures from 1608 to 1860. 3 volumes, Philadelphia, 1861‑1868.

Blake, Nelson

Manfred. Water for the Cities: A History of The Urban Water Supply Problem

In the United States. Syracuse, 1956.

Bowden, Witt. Industrial

Society in England Towards the End of the Eighteenth Century. 2d edition, New York, 1965.

Brainard,

Newton C. "Apollos Kinsley," Connecticut Historical Society

Bulletin, volume 26

(January 1961), pages 12‑20.

Bridenbaugh,

Carl. The Colonial Craftsman. New York, 1950.

Brown, James

S. Allaires Lost Empire. A Story of the Forges and Furnaces of the

Manasquam. Freehold

New Jersey, 1958.

Bruchey,

Stuart. The Roots of American Economic Growth, 1607‑1861: An Essay in

Social Causation New

York, 1965.

Buck, Solon

J., and Elizabeth Hawthorn Buck. The Planting of Civilization in Western

Pennsylvania. Pittsburgh,

1939.

Calendar of

the Miscellaneous Letters Received by the Department of State. From the

Organization of the Government to 1820. Washington, D.C., 1897.

Calhoun,

Daniel Hovey. The American Civil Engineer: Origins and Conflict. Cambridge, 1960.

Calvert, Monte

A. The Mechanical Engineer in America, 1830‑1910. Professional

Cultures in Conflict. Baltimore, 1967.

Carnot, N.‑L.‑S.

Reflections on the Motive Power of Heat, edited by R.H. Thurston. 2d revised edition, New

York, 1897.

Chamberlain, E.