The Metallurgy of

Iron

by

Thomas Turner

Being One of a Series of Treatises on

Metallurgy, Written by Associates of the Royal School of Mines

Charles Griffin & Co., Limited,

Exeter Street, Strand

1908

CHAPTER VII.

Excerpts – pp. 129

- 144

THE AIR USED IN THE BLAST FURNACE.

Blast

Engines.-In India and

other parts of the world where the natives produce wrought iron direct from the

ore, various simple forms of bellows are made from the skin of an animal and

worked by hand; furnaces and bellows of similar design were employed by the

ancient Egyptians many centuries before the Christian era. These were

afterwards replaced by leather bellows with valves, which were at first worked

by hand and afterwards with water power.1 One of the first applications of the steam engine was for

the blowing of air for blast furnaces, and some blowing engines of the early

type are still working in the older iron districts. These engines are of the

Watt pattern, and consist of a massive beam of cast iron supported at the

centre, a steam cylinder being connected to one end of the beam and a blowing

cylinder to the other; low-pressure steam is used, and the engine is worked

with condensers and with a single steam cylinder. Such engines often work for

many years with but trifling repairs, but on account of the great weight of

metal to be moved they can only be driven at a slow rate, they are not so

economical in fuel as more modem engines, and if a fracture of the beam does

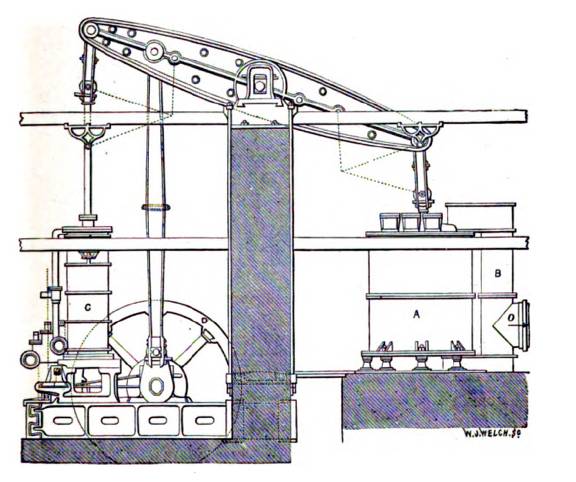

occur it usually occasions much damage and loss of time. A drawing of a blast

engine of this kind is given in Fig. 33, while another illustration of a

similar form, together with the necessary pamps, flywheel, &c., is given in

Dr. Percy's Iron and Steel (p.

387).

Fig. 33 -Beam Blast

Engine. A, Blast cylinder. B, Blast pipe leading to main, 0.C, Steam cylinder.

D. Fly wheel.

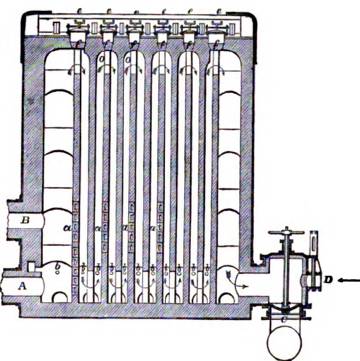

Vertical

direct-acting engines are now generally preferred for producing the blast,

where steam is employed, and the compound principle has been successfully

applied at a number of modem works. As an example of this the blast engines at

the Dowlais Works at Cardiff may be taken. These engines, which are illustrated

in Fig. 34, are worked with a boiler pressure of 100 pounds to the square inch,

and have two steam cylinders, side by side, one 36 inches in diameter for

high-pressure steam, and another, which is steam-jacketed and 64 inches in

diameter, for low-pressure. Connected with, and directly underneath, each steam

cylinder is a blast cylinder 88 inches in diameter. The engines are designed to

ive a maximum pressure of 10 pounds to the square inch, and wworking with a

5-foot stroke at 23 revolutions per minute they give 19,000 cubic feet of air

per minute at atmospheric pressure. There is a separate engine for each

furnace, on the American principle, and the number of revolutions of the engine

is automatically recorded by means of a mechanical counter. The engine is

capable, if necessary, of blowing 25,000 cubic feet of air per minute, and the

pressure actually developed by the engine in ordinary working is rather over 6

lbs. to the square inch.2

A number of American blowing engines

have been illustrated and described in Iron Age, vol. xlvii, pp. 319, 968; vol. x1viii,

pp. 303, 441.

From

information collected by A. von Ihering in 1892 there were in Austria and

Germany 191 blowing engines for blast furnaces; of these 87 were vertical, 70

were horizontal, and 25 were beam engines, while 9 were worked by water power.

It will be thus seen that for blast furnaces vertical engines were generally

preferred, though with higher pressures and smaller volumes of air, as in

Bessemer steel works, horizontal engines are best.3

Fig. 34. -Vertical

direct-acting blast engine (Half Section).

Among

the more recent forms of blowing engines two varieties call for special

mention. Steam turbine engines have been introduced in Cleveland and elsewhere,

and are stated to work very economically and to give a very uniform and steady

air pressure. Large gas blowing engines have also been adopted,

Generally

with marked success. The first blowing engine worked by blast mace gas was

erected at Seraing in 1899. It was of 600 horse-power; was worked with

unpurified gas; and has been fully described by A. Greiner.4 Such engines are now driven by means of

the cleaned surplus gases of the blast furnace, and they will be referred to

later when dealing with the utilization of the waste gases of the furnace in

Chapter VIII. Three important papers dealing with the history and design of

large gas engines for blast-furnace gases will be found in the Journal of

the Iron and Steel Institute,

1906, vol. ii. These papers deal with engines in Belgium, in Germany, and in

the United Kingdom respectively.

Application

of Hot Blast.-The

original patent, No. 5,701, granted to J. B. Neilson, of Glasgow, on l1th

September, 1828, for "improved application of air to produce heat in

fires, forges, and furnaces where bellows or other blowing apparatus are

required," reads an follows;

" A blast or current of air must be

produced by bellows or other blowing apparatus in the ordinary way, to which

mode of producing the blast or current of air this patent is not intended to

extend. The blast or current of air so produced is to be passed from the

bellows or blowing apparatus into an air vessel or receptacle, made

sufficiently strong to endure the blast and through and from that vessel, by

means of a tube, pipe, or aperture, into the fire, forge, or furnace. The air

vessel or receptacle must be airtight or nearly so, except the apertures for the

admission and emission of the air; and at the commencement and during the

continuance of the blasting it must be kept heated artificially to a

considerable temperature. It is better that the temperature be kept to a red

heat or nearly so, but so high a temperature is not absolutely necessary to

produce a beneficial effect. The air vessel or receptacle may be conveniently

made of iron, but as the effect does not depend on the nature of the material,

other metals or convenient materials may be used; the size of the air vessel

must depend upon the blast, and on the heat necessary to be produced. For an

ordinary smith's fire or forge, an air vessel or receptacle capable of

containing 1,200 cubic inches will be of proper dimensions; and for a cupola of

the usual size for cast iron founders, an air vessel capable of containing

10,000 cubic inches will be of a proper size. For fires, forges, or furnaces,

upon a greater scale, such as blast furnaces for smelting iron, and large cast

iron founder's cupolas, air vessels of proportionately increased dimensions and

numbers are to be employed. The form or shape of the vessel or receptacle is

immaterial to the effect, and may be adapted to the local circumstances or

situation. The air vessel may generally be conveniently heated by a fire

distinct from the fire to be effected by the blast or current of air, and

generally it will be better that the air vessel and the fire by which it is

heated should be enclosed in brickwork or masonry, through which the pipes or

tubes connected with the air vessel should paw. The manner of applying the heat

to the air vessel is, however, immaterial to the effect if it be kept at a

proper temperature."

From

the above specification, to which no drawings were attached, it will be

observed that Neilson claimed no special form of apparatus, but merely the

principle of employing heated air for combustion. How far he at the time

correctly understood the facts underlying his invention is doubtful, but it is

interesting to notice that even in his original specification Neilson mentioned

the use of a red heat, and throughout his whole life he consistently advocated

the use of the highest attainable blast temperature; the temperature obtained

with the apparatus at first introduced was, however, far below redness.

Theory

of the Hot Blast.-It may

at first sight appear strange that any economy should result from the use of

hot blast, and in the early days of this discovery it was urged that a given

weight of fuel burned in the furnace would give as good a result as if part

were burned inside the furnace and part employed to heat the blast. The

following are some of the more important reasons for the economy observed with

hot blast:

1. In the lower part of the blast furnace

carbon is not oxidized to carbon dioxide (CO2), but only carbon monoxide (CO)

is produced. The combustion of carbon by air forced into the blast furnace,

therefore, generates only 2,473 centigrade heat units, while when complete

combustion takes place, as in heating the blast, carbon generates 8,080 heat

units. The heat liberated by a unit of carbon burned in heating the b1aat is

thus more than three times as great as that yielded by a unit of carbon burned

in the blast furnace.

2. The use of hot instead of cold blast

naturally increases the temperature of combustion near the twyers, and this

assists in the rapid melting of the slag and iron.

3. When the temperature is sufficiently

high, carbon is at once converted into carbon monoxide, and the heat of

combustion is thus localised. In a furnace using cold blast, carbon dioxide is

produced near the twyers, this is decomposed into monoxide somewhat higher in

the furnace, with the result that the reaction is completed further away from

the twyers than with hot blast.

4. Owing to the more local combustion,

and smaller quantity of air employed with hot blast, the upper part of the

furnace is cooler, and the escaping gases carry off much less sensible heat.

5. Owing to the diminished consumption of

fuel, due to the above causes, less ash has to be converted into slag, loss

flux is n6eded, and thus fuel is saved.

6. As less fuel is required with hot

blast, less time is needed for its combustion. A furnace of given capacity

contains more ore, and the yield of the furnace is largely increased.

Although

the heat generated is greater when carbon is burned to CO2 than when CO is

obtained, the temperature is locally higher in the latter case. This is owing

to the fact that CO2 begins to dissociate into CO and O at about 1,200 C to

1,300 C., and hence CO can only be completely burned to CO when the temperature

of combustion does not much exceed 1300 C. It is for this reason that the hot

blast, by leading to the immediate formation of CO, yields a higher temperature

in the hearth than would be possible if CO2 were there produced.

The

sensible heat brought into a blast furnace by the blast is generally about

one-seventh of that required by the furnace, though the proportion will vary

with the temperature and volume of blast. A useful table has been prepared by

C. Cochrane,5 giving the equivalent in cwts. of coke,

of the heat brought in by the blast; in this table the weight of blast ranges

from 55 cwts. to 145 cwts. per ton of iron produced, and the temperature from

10 to 800 C., and it thus includes all variations met with in practice.

Limit

to the Advantages of Hot Blast.-It

is obvious that there is a theoretical limit to the temperature which can with

advantage be imparted to the air used in the blast furnace, for since a

reducing agent is necessary to remove the oxygen of the ore, it is not possible

to smelt iron with hot air alone, or with less than the quantity of carbon

needed to remove the oxygen. If, therefore, the minimum quantity of carbon

required for combination were ever reached, it would be useless to further

increase the temperature of the blast. It must be remembered that there are

difficulties in the way of heating air much above the temperature now

attainable, and these difficulties are very great - if not insurmountable.

Owing to the dissociation of carbon dioxide at temperatures little above the

melting point of steel, the combustion of carbon is incomplete, and its full

calorific power cannot be obtained. At the game time the lose by radiation, and

the wear of the heating apparatus, increase rapidly at high temperatures, so

that it becomes more and more costly to raise the air through each succeeding

increment of temperature. This question has been dealt with at considerable

length by Sir L. Bell6 who shows that the saving of fuel on raising

the blast from 1,000 F. to 1,700

F. was only 1 cwt. per ton of iron made, and concludes that it is not

economical to raise the temperature beyond 1,700 F. Sir L. Bell's conclusions

would, however, need some revision in view of modem practice with good

fire-brick stoves, as it does not appear that in actual working the economical

limit has been yet often exceeded or even reached.

Methods

of Heating the Blast.-The

apparatus employed by Neilson in his first practical application of the hot

blast early in 1829 at the Clyde Iron Works, Glasgow, is shown in the following

figure.

NeilsonŐs original hot

blast apparatus, 1829

.It

consisted of a small wrought-iron heating chamber, 4 feet long, 3 feet high, and

2 feet wide, which was set in brickwork with a grate below like a steam boiler.

The cold blast entered immediately over the grate and passed out at the

opposite end, being warmed in its passage to about 200 F. The blast entered the

furnace by means of 3 twyers, each of which was provided with a similar heating

box. This apparatus was only capable of warming the air, but the results

obtained were such as to indicate the great advantages to be derived from the

application of hot blast. The wrought-iron chamber thus employed not only had

the disadvantage of exposing little heating surface to the blast, but it was

soon burned out and required renewal. It was, therefore, replaced by a

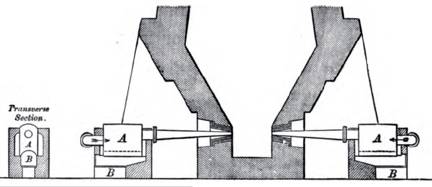

cylindrical cast-iron tube (A), set horizontally in a heating chamber (B) (see

Fig. 35), and, as before, each twyer was provided with a separate heater. These

horizontal pipes gave a higher temperature, but such an arrangement led to

irregular heating, and to much trouble with the expansion and the contraction

of the pipes. Full details of Neilson's early forms of apparatus are given by

H. Marten,7 from whose paper the accompanying

sketches are reproduced.

Fig. 35.-Neilson's

cylindrical oven.

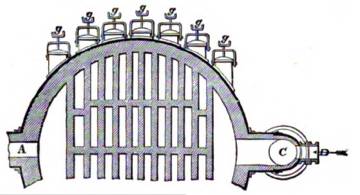

The

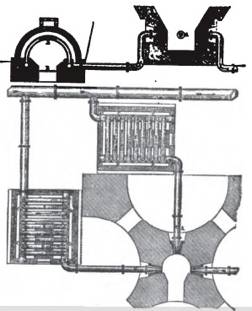

first cast-iron tubular oven was erected at the Clyde Works in 1832, and is shown

in Fig. 36.

Fig. 36. - Original

tubular oven.

From

this it will be seen that the blast furnace was supplied with 3 twyers, to each

of which was attached a stove, which consisted of a chamber of brickwork,

heated by means of a fire grate placed underneath, and through which the air

passed in a series of circular cast-iron pipes, which were arched over the

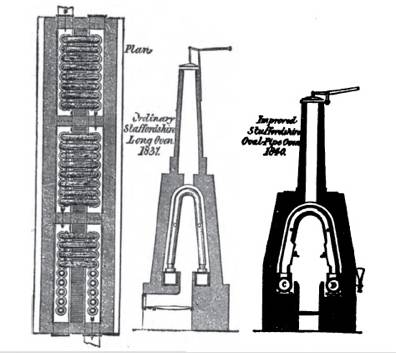

fireplace as shown in the sketch. Hot-blast stoves on this principle were soon

adopted in all the chief iron-making districts, numerous modifications of

detail being introduced from time to time. In order to diminish the

difficulties due to expansion of the metal a U or V shape was employed for the

pipes, while to give greater heating surface they were cast with an elliptical

section. The stoves were built larger so as to do away with the necessity of a

separate heating arrangement for each twyer, while in order to obtain a higher

temperature each stove was divided into several separate chambers, and the air

caused to pass through these in succession (Fig. 37).

Fig. 37

To

economise space in some cases circular ovens were constructed on similar

principles; the first circular hot blast stove was erected by M. Baldwin in

1851 at Bilston in Staffordshire, and though the heat so obtained was not

greater than in the rectangular form, the trouble due to leakage and fractures

was much diminished (Fig. 38).

Fig. 38 Round and long ovens

A form of stove which also met with

considerable favour was introduced by Mr. Baird at Gartshorrie, and known, from

the peculiar shape of the heating pipes, as the "pistol pipe" stove:

this is shown in Fig. 39, from which it will be seen that the pipes are divided

by a partition which passes throughout the greater part of their length, and

the air, instead of passing across the stove is made to travel up on the

outside and down the inside of the same divided tube.

Fig. 39. -Pistol pipe

stove.

Gas-Fired

Regenerative Stoves.-The

early forms of hot blast stove were all heated by the combustion of solid fuel,

and although in 1833 Faber du Faur invented a hot-blast stove heated by the

combustion of the waste gases from the blast furnace, and experiments in the

same direction were conducted at Wednesbury in the following year, it was not

until after BuddŐs patent of 1845 that this system of heating was successfully

introduced. Direct-firing stoves held their own side by side with gas-fired

stoves, for a number of years, until the regenerative system invented by

Siemens was applied to heating the blast, with the waste gases, by E. A. Cowper

in 1860. A history of the development of fire-brick stoves has been given by

Luhrman.8

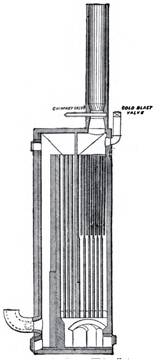

The

Cowper Stove, which is shown in sectional elevation in Fig. 40, consists of an

outer shell of plates of wrought iron or mild steel, riveted to form a

cylindrical chamber some 60 feet high, 28 feet in diameter, and with a

dome-shaped roof. This chamber is lined internally with firebrick, a circular

flue extends from the bottom to the top, while the rest of the chamber is

filled with fire-bricks. The waste gases from the blast furnace enter the

Cowper stove by the gas valve shown in the sketch; the air required for

combustion enters at the air valve, and combustion takes place at A at the base

of the internal gas flue. The hot products of combustion pass downwards through

the regenerator of honeycomb brickwork to the exit valve, which is connected

with the chimney. The mass of brickwork in the regenerator absorbs heat from

the hot gases, and itself becomes red hot, particularly in the upper portion.

When this has gone on sufficiently long to thoroughly heat the brickwork, the

air, gas, and chimney valves are closed, and cold blast is admitted through the

cold-blast main in the opposite direction, when it takes up heat from the

brickwork, an is delivered to the furnace through the ho tblast valve. It in

necessary to have at least two stoves for each blast furnace, so that one may

absorb beat while the other is heating the blast, and it is advisable to also

have a stove in reserve in case of accident. Where blast of higher temperature

than usual in required, as with rapid production, four firebrick stoves are

usually provided for each furnace.

Fig. 40. -Cowper's

hot-blast stoves. Scale, about 60 feet to an inch.

In

the original Cowper stove the bricks were arranged without any binding

material, loosely, as in the Siemens regenerator. Afterwards, about 1875, the

bricks were arranged in rows, with every other brick projecting so as to form

vertical channels. The honeycomb brick employed for the regenerator of the

modern Cowper stove is illustrated in Fig. 41, and is designed, when the bricks

are placed together, so as to form hexagonal gas passages, all of which have

walls of Stourbridge or other refractory fire-clay, 2 inches in thickness. Each

brick is 6 inches in height, and weighs about 32 lbs. In plan these bricks

consist of a hexagonal air passage, the greater diameter of which is 7 inches,

surrounded by a wall of fireclay 2 inches thick; at each of the six comers of

this hexagonal wall, a short projecting wall 2 inches square and 6 inches high

is attached in the direction of the longer diameter, the whole forming one

brick. The projections are so arranged that, on placing the bricks into

position side by side in the stove the whole of the interior is divided into

upright hexagonal air passages, with a larger diameter of 7 inches, and with

fireclay walls 2 inches thick. The bricks are made by pressing the clay into a

column of the required shape by suitable machinery, and cutting off horizontal

slices from this column each 6 inches high; these are dried and baked in kilns

before use. The bricks were formerly reamed separately by hand, but this method

has been replaced y that just described.

Fig. 41. -Honeycomb brick.

The

combustion flue inside the Cowper stove is usually circular in cross section,

but it is found that with this form the pass have a tendency to pass chiefly

down the centre of the brickwork filling, this being the shorter path, and to

leave the corners comparatively cool. In order to equalise the distribution of

the gases, a D-shaped combustion flue has been introduced as described by W. J.

Hudson (S. S. Inst,

Nov. 1891, Discussion), with the result that the crescent-shaped corners in the

filling of brickwork have been done away with, and a more uniform heating

obtained. At Friedenshfitte, in Upper Silesia, the same object is obtained by a

modification due to Bucker, who, instead of giving a uniform cross-section to

the brickwork passages of the stoves, makes those in the centre, where the

gases travel a shorter path, smaller than those at the sides through which the

travel is longer; this is illustrated in Inst, Journ., 1890, vol. ii., p. 516, and some such

method of equalisation is now frequently adopted.

The

hot-blast valve of a Cowper stove is shown in Fig. 42. The valve seat is of

cast-iron; a wrought iron tube being cast in, and water circulated through the

tube to protect the casting from over-heating. The valve itself is of steel,

and has a sheet of asbestos on each side, which is kept in place by a plate;

this prevents the valve from burning at the high temperatures employed. The

usual temperature obtained by Cowper stoves as employed for blast furnace

purposes is 1,500 F. (815 C.), but a temperature of 2,000 F. can be attained if

desired.9

Fig. 42 Hot Blast

Valve

As

compared with pipe stoves the Cowper stove gives a much higher temperature, and

has thus led to an increased yield of about 20 per cent. from similar furnaces;

the fuel consumption is at the same time lessened; in some experiments

conducted by Mr. Hawdon the quantity of gas required by a Cowper stove was only

two-thirds of that of a pipe stove, while the temperature obtained was

1,500 as against 1,000 F. These

advantages have been so fully proved that hundreds of Cowper stoves are now in

use throughout the world, and a number of modifications of the regenerative

fire-brick stove have also been introduced. The Cowper stove probably gives the

highest temperature of any of these varieties, but it has the disadvantage of

being somewhat easily clogged with dust, especially when smelting

finely-divided or manganiferous ores. To minimize this difficulty dust catchers

are often employed (see p. 119). As furnace gases will in future be more

perfectly freed from dust than was formerly the case, the dust nuisance is not

likely to cause as much inconvenience as heretofore. But even under the most

favourable conditions dust accumulates in the Cowper stove, and necessitates.

occasional cleaning. For this purpose C. Wood, of Middlesbrough, employed a

small bronze cannon, which was charged with powder and run into the stove to be

cleaned when the blast was turned off. The charge was fired from outside by

means of a sliding hammer which struck a percussion cap, and which was set in

motion by blowing down a long india-rubber tube. The explosion thus caused

displaced the dust, which was allowed to settle and was afterwards removed.

Another method of cleaning such stoves, which is now in pretty general use,

depends on the use of release valves, such an Lister's, which allow of the

instantaneous discharge of the imprisoned air; in order to remove the dust the

fall blast pressure is turned into the stove, and then by the release valve

this is allowed to pass instantaneously into the chimney. A cloud of dust is

immediately discharged, and being shot up into the air is often visible for

considerable distances. Cowper stoves are now not infrequently raised on

columns so as to allow men to stand underneath for cleaning with a scraper.

This is done at casting time and after the stove has been ou blast for some

time, as the bottom is then comparatively cool.

The

Whitwell Stove.-The

first Whitwell stove was erected at the Thorrnaby Iron Works at

Stockton-on-Tees in 1865. This store is also a regenerative gas-fired stove~

and like the Cowper is constructed of plates of iron riveted together to form a

cylinder, which in modern stoves is some 65 feet high and 25 feet in diameter,

with a dome-shhaped top, and lined throughout with fire-brick. But the internal

arrangement of the two stoves is quite different. Figs. 43 and 44 show a

vertical and horizontal section of a Whitwell stove, in the interior of which

is a regenerator which consists of a series of vertical firebrick passages made

of 5-inch brickwork. The gas is admitted at A at the bottom of the combustion

chamber, while air is introduced by feed passages (a), and the products of

combustion pass to the chimney through the flue (C). The hot and partly burned

gases pass repeatedly up and down through the brickwork passages, and after

giving up their heat to the stove, ultimately leave at a low temperature. Air

is admitted by valves into the feed passages so as to complete the combustion

as the gases pass through the stove, and in this the Whitwell principle differs

from that adopted by Cowper. When the brickwork is thoroughly hot, the gas is

turned off, the cold blast enters the stove at D, takes up heat from the heated

brickwork, and passes out at B on its way to the furnace. The Whitwell stove

not only offers less opportunity for the accumulation of dust, but also, on

account of the shape, allows of more ready cleaning while at work, and is thus

in favour where the gases are more than usually dusty. The stove shown in Figs.

43 and 44 is of the original pattern introduced by Mr. Whitwell; it was 25 feet

high and had a flat roof. The more recent forms are about 70 feet in height,

while an arched top, like that of the Cowper stove, is also adopted.

Fig. 43.

Fig. 44.-Whitwell stove.

Original form.

A

number of modifications has been introduced in the construction of fire-brick

stoves in America~ one common plan being to make them quite independent of the

draught of the stack by providing a separate chimney, with a valve at the top

of each store, but this method has not been adhered to in some of the later

installations. The arrangement of the regenerator has also been modified in

many ways. In the Gordon-Cowper- Whittwell pattern, which is very popular in the Southern States, and

which is shown in sectional elevation in Fig. 45, both the Whitwell and the

Cowper systems are combined, while a separate chimney is provided as is usual

in America. It is claimed that such stoves have the advantage that gases which

contain a considerable proportion of dust may be employed, while as the latter

part of the regenerative action is conducted by Cowper bricks, the gases are

efficiently cooled, and a high temperature can be imparted to the blast.10

In

the Massick & Crookes Stove

the regenerator is on the Whitwell principle, but arranged in what, is known as

a three pass" system; the

main combustion tube is placed in the centre of the stove, and the gases after

passing up the central tube pass ones down and onceup through gas pass-ages

similar in principle to those of the Whitwell stove, but arranged

concentrically around the main combustion tube. The products of combustion pan

out at the top of the stove by a separate chimney11.

Fig.

45.-Gordon-Cowper-Whitwell stove

The

Ford & Moncur Stove was

introduced in Cumberland some years ago, and has since met with considerable

favour12

.This stove is on the

fire-brick regenerative principle, with the usual external casing of iron

plates lined with fire-brick. The modifications introduced are intended chiefly

to facilitate cleaning: for this purpose bricks are employed, the upper edges

of which are dormer-shaped so as to prevent the dust lodging; the stove is also

divided into four separate parts by vertical partitions, so that, when it is

desired to clear out the dust, the blast is turned on to each section

separately, and by proper release valves the air is allowed to suddenly escape

and so carry away the dust, and it is claimed that the stove can thus be

readily kept clean without any necessity for stoppages. Instantaneous release

valves, invented by Lister, have also been pretty largely adopted for cleaning

other varieties of hot-blast stoves, and materially reduce the deposit which

accumulates during the heating by gas. Hot-blast valves were formerly a source

of much trouble, owing to the burning of the seat and consequent leakage.

Westray and Copeland have overcome this difficulty by the use of cast-iron

valves which have a pipe coiled round the seat; by circulating water through

this pipe the seat is cooled and lasts much longer; at the same time

arrangements are made for bolting on the seat, so that it can be readily

changed when necessary.

1. The

"Development of Blast-Furnace Blowing Engines," from the earliest to

the more modern forms, has been dealt with by D. E. Roberts (Inst. M. E.

Cardiff Meeting, 1906).

2. Inst. Journ, 1899, vol. i, p. 19.

3. Inst. C. E.., vol. exii., p. 432

4. Inst. Journ., 1900. vol. i p. 109.

5. Inst. M. E., 1883, p. 124.

6. Principles, sects. 6 and 7. See

also Inst. Journ.,

1893, vol. ii., p. 242.

7. Inst. M. E, 1859, p. 62

8. Inst. Journ., 1890, yol. ii., p.

754.

9. E. A. Cowper, J. S. C. 1., 1893, p. 311; also S.

Staff. Inst.,

Sept., 1884.

10. Inst Journ. (Amer. vol.), p. 335.

11. Inst. Journ., 1890, vol. ii., p.

340; also ibid.,

Plate 24.

12. Ibid, 1890, vol. i, p. 391.

Return to The Anthracite Iron Industry page

About The Hopkin Thomas Project

Rev. February 2010