REMINISCENCES

OF THE

EARLY ANTHRACITE-IRON INDUSTRY

BY

SAMUEL THOMAS

Catasauqua, pa

AN ADDRESS DELIVERED BEFORE THE

AMERICAN INSTITUTE OF MINING ENGINEERS, AT THE CALIFORNIA MEETING, SEPTEMBER,

1899.

_________

Published from Advance Sheets of Vol. XXIX of the

Transactions

______________________

AUTHOR'S EDITION.

1900.

[TRANSACTIONS OF THE AMERICAN INSTITUTE OF MINING

ENGINEERS]

Reminiscences of the Early Anthracite-Iron

Industry.

BY SAMUEL THOMAS,

CATASAUQUA, PA.

(An Address at the

California Meeting, September, 1899.)

THE

specimen of anthracite coal which I hold in my hand, insignificant as it may

appear to the casual observer, speaks volumes to me and to the initiated, as it

suggests and represents the entire evolution of the use of anthracite coal in

the manufacture of pig-iron, the growth and development of which it is my

purpose to review here to-day.

During

our recent visit to the Mountain Copper Co.'s works at Keswick, I picked up

this piece of coal from a pile of anthracite lying in the yard, asked Mr.

Edwards, the manager, a countryman of mine, where it came from, and, to my

surprise and delight, discovered that it had been brought all the way from

Wales, and had come out of the identical vein which my father opened near

Yniscedwin, about eighty years ago. I had no idea, before this incident, of

contributing to the already full and complete programme of the day; but, being

requested by our distinguished President and Secretary to do so, I consented to

relate here the story which this remarkable find naturally brought back to my

mind.

David

Thomas, my revered father, called by his Welsh countrymen "the pioneer of

the anthracite iron-trade in America," was one of the principal actors in

the history of manufacturing pig-iron with anthracite coal. I shall give here

my personal recollections of his early experiments, trials, and: final

successes, as frequently related by him to me, together with quotations from a

biographical sketch by E. Roberts, found in the number for October, 1883, of

the "Red Dragon," the, national magazine of Wales. Mr. Roberts'

narrative is authentic by reason of his free access to the records of the Yniscedwyn

anthracite iron-works during his long connection with them. He says:

"Mr.

David Thomas was the only, son of David and Jane Thomas, of Tyllwyd, (Gray

House), in the parish of Cadoxtan, Glamorganshire, South Wales. Here he was

born November 3rd, 1794. David Thomas, his father, was one of the numerous poor

farmers of the country, but a man highly respected in his parish, where,

although a dissenter, be held the honorable office of church-warden in the Established

Church, and was overseer of the poor for sixteen years. Young David's early

religious and moral training was of the strictest kind, both as regards example

and precept; and he clung to these deeply inculcated principles all through

life. Being an only son, his parents were anxious to give him the best

advantages their means allowed, and the district afforded; and be attended

school at Alltwen (White Grove), where he made such progress that, when nine

years old, he was removed to a more advanced school at Neath, his father paying

one guinea a quarter for tuition, which, at that remote period, was considered

a large amount The lad, studious by nature, delighted in books, and in

acquiring knowledge and information, and was determined to get on. He soon outstripped

all his school-fellows, and yet had succeeded in acquiring only the elements of

an education, as compared with the opportunities offered the boys of today.

It

was by dint of undaunted perseverance, industry and personal effort that he

attained the prominent position to which he ultimately rose. David was often

called upon to assist in the operations of the farm; but agricultural pursuits

were not to his taste, and his thirst for knowledge and improvement awakened in

him an ambition which small farming- interests failed to satisfy. In 1812, when

17 years of age, he determined to branch out in a line of life which presented

better prospects, and accordingly found employment at the Neath Abbey

iron-works, erected on the navigable river Neath. They consisted of two

cold-blast coke furnaces, machine-shops and foundry, owned by a fine old Quaker

gentleman named Price, who was one of the largest builders of mining-machinery

and Cornish pumping-engines of that day. Here young David spent five years; acquiring

his technical training in the machine-shops and foundry, while devoting his

leisure hours to the study of the workings of the blast-furnaces. In 1817, when

23 years of age, after having spent several months in Corneal erecting a

pumping-engine, be went to the Yniscedwyn iron-works, then owned by Richard

Parsons, and here was made general superintendent of the furnaces and of tile

coal- and iron-mines, which position he occupied for twenty-two years, working

the furnaces most successfully.

"Some

three years later, these works came under the control of George Crane, after

whom the Crane iron-works at Catasauqua, Pa., were named.

"It

so happened that the Yniscedwyn works actually stood on the only basin of

anthracite coal in Great Britain, which contains several veins, and extends

from the upper part of the Vale of Neath in Glamorganshire, on the east, to

Saundersfoot in Pembrokeshire, on the west, the plant being on the southern

edge of the coal-field in the Swansea valley; and yet, although these furnaces

were underlain and surrounded with this valuable material, coke was brought a

distance of fourteen miles to supply them with fuel. Throughout this entire

basin the argillaceous clay-iron-stone and 'black band' are stratified, and

supplied the furnaces of that region with iron-ore.* Mr. Thomas was often heard

to say that the Almighty had not wasted His creative powers in putting these materials

together for no purpose; and on that faith he began his experiments.

*These

ores were long since exhausted; and every furnace in that region has been in

rains these twenty-five years and more.

"As

early as 1820 Mr. Thomas began to experiment with anthracite coal in the blast-furnaces,

using it with coke in the proportion of from 1 part in 20 to 1 part in 12.

'This did very well,' Mr. Thomas used to say; but whenever anything went wrong

with the furnaces the fault was always laid on the coal; and the men became so prejudiced against it

that I had to give it up. Still, every year I would try some experiments with

it, both in cupola and blast-furnace.' . . . 'In 1825 1 had a small furnace

built, 28 feet high and 9 feet bosh, which was put in blast with coke and an increased amount of anthracite. Results

were not satisfactory, and this furnace was abandoned. In 1830 the same furnace

was made 45 feet high and 11 feet

bosh; and, while the experiments were much more successful than previously, the

consumption of coal was so great as to make results unprofitable, and the work

was again abandoned,'

Mr.

Roberts continues:

"About

this time experiments were also being made in Pennsylvania, but with its better

success than in Wales. While this was being done on both sides of the Atlantic,

another brain was at work, which furnished the key that unlocked the secret to

success, by Mr. Neilson of Glasgow, the inventor of the hot-blast, who in 1828

obtained a patent for his valuable invention, the importance of which was not

realized for a long time. The pamphlet on the hot-blast, issued by Neilson, was

eagerly read by Mr. Thomas, who was at once convinced of the value of the

discovery. One evening, while sitting with Mr. Crane in his library, talking

the matter over, he took the bellows and began to blow the anthracite fire in

the grate. 'You had better not, David,' said Mr. Crane; 'you will blow it out.'

And Thomas replied, 'If we only had Neilson's hot-blast here, the anthracite

would burn like pine.' Mr. Crane said, 'David, that is the idea precisely,' and

this idea both recognized as one which would bear working out; and through Mr.

Thomas's indomitable pluck and perseverance it succeeded. In fact, this was the

origin of the successful application of the hot-blast in making iron with

anthracite. In the meantime the Clyde iron-works, in Scotland, had put a

furnace in operation, using the hot-blast with semi-bituminous coal in the

furnace. Mr. Thomas urged upon Mr. Crane the immediate adoption of the new

discovery, and he was sent to Scotland to see how the process worked. After the

most careful examination, Mr. Thomas determined that the hot-blast was just

what was wanted for an anthracite furnace. He returned to Yniscedwin with a

license from Mr. Neilson, and an expert mechanic who understood the

construction of beating ovens, and at once proceeded to construct hot-blast

ovens, and erected them at the furnace which was known as the 'Cupola furnace,'

11 feet bosh by 45 feet high. The furnace was blown in, February 5, 1837; the

success was complete; and anthracite-iron continued to be profitably made from

said furnace without intermission.

"Anthracite-iron

was a new-born commodity in the commerce of the world, and David Thomas was its

godfather. The news of his success spread over the United Kingdom; the London Mining

Journal gave

it great prominence; and an account of the discovery appeared in the press of

the United States."

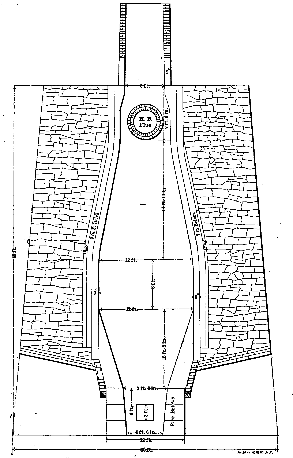

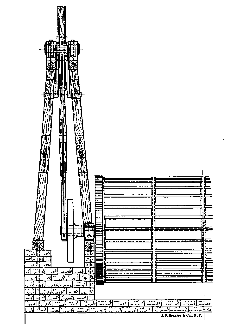

Fig.

1, copied from Truran's work on "Iron," shows the lines of the

"cupola furnace" mentioned in the historical summary quoted above.

In

May, 1837, Solomon W. Roberts of Philadelphia came to Yniscedwin, saw the

furnace in operation, and at once reported to his uncle, Josiah White, of the

Lehigh Coal and Navigation Company, the successful application of the hot-

blast there.* At this time, 1837-38, the Lehigh Coal and Navigation Company,

and other companies whose splendid mines cluster in the neighborhood of Mauch

Chunk, Pa., were experimenting in the use of anthracite in the blast-furnace,

but with such small success that

it was determined to send Mr. Erskine Hazard, one of the leading spirits of the

company, and afterwards the leading spirit of the Lehigh Crane Iron Company,

over to Wales, to investigate, the practice at Yniscedwin and engage a competent

person to come to this country to superintend the erection of furnaces on the

Lehigh. Mr.. Hazard arrived in November, 1838, and found the furnace in full

and successful operation.

Cupola

Furnace," Built at Yniscedwin Works, South Wale in 1836, and Successfully

Blown-in, in February, 1837.

Prior

to this date, my father had removed his family to Devynock for the better

education of his children; and there, in addition to his other duties, he

constructed a tramway to the mines and furnaces, the road-bed of which is

occupied to-day by the Swansea, Neath and Brecon railroad. Mr. Crane brought

Mr. Hazard to our home, near Castle Dhu (Black Castle), a feudal ruin of the

twelfth century. He was accompanied by his oldest son, Alexander Hazard, at present,

a resident of Catasauqua, Pa. Here took place the first interview with my

father with in relation to his going to America, Mr. Crane having strongly

recommended him to Mr. Hazard as the only man who would answer the purpose. My

father was very loath to leave his native land, chiefly on account of his aged

mother; but at the persuasion of his ambitious and energetic wife, who felt

that the new world held larger opportunities for her three sons, he entered

into the following agreement, which was executed the last day of the year 1838.

All the details of this transaction I remember distinctly, having, been present

on the occasion:

*Mr.

Roberts was then located at the Dowlais iron-works, WaIes, inspecting rails for

his company, which was constructing a railroad between White Haven and

Wilkesbarre. These rails were double-beaded. About thirty-five years later the

writer, then President of the Catasauqua Manufacturing Company, bought a

quantity of these identical rails, which were rolled into spike-rods.

Memorandum

of Agreement Made the Thirty-first Day of December, 1838, between Erskine

Hazard for the Lehigh Crane Iron Company of the One Part, and David Thomas, of

Castle Dhu, of the Other Part.

1.

The said Thomas agrees to remove with his family to the works to be established

by the said company on or near the River Lehigh, and there to undertake the erection

of a blast-furnace for the smelting of iron with anthracite coal, and the

working of the said furnace as furnace-manager; also to give his assistance in

finding mines of iron-ore, fire-clay, and other materials suitable for carrying

on iron-works, and generally to give his best knowledge and services to the

said company, in the prosecution of the iron business, in such manner as will

best promote their interests, for the term of five years from the time of his

arrival in America, provided the experiment of smelting iron with anthracite

coal should be successful there.

2.

The said Hazard, for the said company, agrees to pay the expenses of the said

Thomas and his family from his present residence to the works above mentioned

on the Lehigh, and there to furnish him with a house and coal for fuel also to

pay him a salary at the rate of two hundred pounds sterling a year from the

time of his stipend ceasing in his present employment until the first furnace

on the Lehigh is got into blast with anthracite coal. and making good iron,

and, after that, at the rate of two hundred and fifty pounds sterling a year

until a second furnace is put into operation successfully, when fifty pounds

sterling shall be added to his annual salary, and so fifty pounds sterling per

annum additional for each additional furnace which maybe put into operation

under his management.

3.

It is mutually agreed between the parties that should the said Thomas fail of

putting a furnace into successful operation with anthracite coal, that in that

case the present agreement shall be void, and the said company shall then pay

the said Thomas a sum equivalent to the expense of removing himself and family

from the Lehigh to their present residence.

4.

In settling the salary, four shillings and sixpence sterling are to be

estimated as equal to one dollar.

In

witness whereof the said parties have interchangeably set their hands and seals

the date above given.

ERSKINE HAZARD, (SEAL)

for

Lehigh Crane Iron Comp'y.

DAVID

THOMAS. (SEAL)

Witness

ALEXANDER

F. HAZARD.

It

is further mutually agreed between the Lehigh Crane Iron Company and David

Thomas, the parties to the above-written agreement, that the amt. of the D.

Thomas salary per annum shall be ascertained by taking the United States Mint

price or value of the English sovereign as the value of the pound sterling,

Instead of estimating it by the value of the dollar as mentioned in the 4th

article, and that the other remaining article in the above-written memorandum

of agreement executed by Erskine Hazard for the Lehigh Crane Iron Co. and David

Thomas be hereby ratified and confirmed as they now stand written.

This

supplementary agreement was also duly executed.

The

organization of the Lehigh Iron Co., prior to Mr. Hazard's going abroad, had

been only an informal one. On Jan. 10, 1839, it was perfected, and the first

meeting of the directors was held. The Board consisted of Robert Earp, Josiah

White, Erskine Hazard, Thomas Earp, George Earp, John McAllister, Jr., and

Nathan Trotter. They organized by electing Robert Earp President and Treasurer,

and John McAllister, Jr., Secretary. In April they entered into articles of

association, which are appended, as affording some idea of the foundation on which

this staunch old company has arisen and flourished.

Articles

of Association of the Lehigh Crane Iron Co., Made and Entered into Under and

Pursuant to an Act to Encourage the Manufacture of Iron with Coke, or Mineral

Coal, and for Other Purposes, Passed June 16, 1836.

WITNESS

that the subscribers, citizens of Pennsylvania, whose names are hereto affixed,

have associated themselves, under and pursuant to the Act aforesaid, for the

purpose of making and manufacturing iron from the raw material with coke or

mineral coal, and do certify and declare the articles and conditions of their

association to be as follows :

Article

1. The name, style, or title of the company shall be Lehigh Crane Iron Co.

Art.

2. The lands to be purchased by the company shall be in Northampton, or Lehigh

county, or both.

Art.

3. The capital stock of the company shall consist of one hundred thousand

dollars, divided into two thousand shares of fifty dollars each, the whole of which

bas been subscribed for by the subscribers hereto, in the numbers of shares set

opposite to their respective names.

Art.

4. The sum of twenty-five thousand dollars, being the one-fourth of the whole

capital stock subscribed for, has been actually paid in.

Art.

5. The remaining installments on the stock, already subscribed for, shall be

called in such sums, and at such times, and with such forfeiture for

non-payment thereof, as the Board of Directors may prescribe.

Art.

6. The Board of Directors' shall consist of such a number of persons as the

stockholders may from time to time prescribe.

Art.

7. This company shall in all things be subject to and governed by the

provisions of the Act of Assembly under which it is created, and shall have the

same and no other or greater powers, privileges, and franchises than are

conferred upon it by virtue of the said Act.

PHILADELPHIA,

April 23, 1839.

Signed JOSIAH

WHITE, JOHN

McALLISTER, JR.,

ERSKINE

HAZARD, ROBERT

EARP,

THOMAS

EARP, THEODORE

MITCHELL,

GEORGE

EARP, NATHAN

TROTTER.

The

first week of May, 1839, found our little family group at Swansea, on board of

one of the coast-steamers on our way to Liverpool, as there were no railroads

across the country at that time. The steamer "Great Western" had made

but two or three voyages across the Atlantic; so, after much discussion among

the parties interested, it was decided that, as steam was still considered a

dangerous venture, we should take a sailing-vessel; and our passage was engaged

on the clipper ship "Roscius" commanded by Captain Collins, cousin of

E. K. Collins, of the celebrated line of steamers of that name. The

"Roscius" and the "Great Western" left port on the same

day; the steamer arriving in New York but four days in advance of the clipper,

which had an unprecedented voyage of twenty-three days. Our first month on

American soil was spent in New Brighton, Staten Island, where my father lay

very ill of a fever, and was faithfully attended by Dr. Harcourt, the genial

quarantine-physician. On his recovery, he took me with him to Philadelphia,

where he had been called to attend a meeting of the Crane Co.'s Board, relative

to his entering upon his duties. We returned to New Brighton July 4, and two

days later turned our faces toward the Lehigh Valley, our future home, taking

the New Jersey railroad via Jersey City and New Brunswick, at that time the

terminus of the road, which, it may be of interest to note, was laid with

strap-rails.

From

New Brunswick the journey was continued by stage, the first night being spent

at Easton, and Allentown being reached July 9. Here we resided four months

while our home was being built near the new works. On July 11 my father and I

started on foot for the site of the future works, near what was-then known as

Biery's bridge, where we spent several hours, making measurements from which to

work out plans for the construction of the plant, I, then a boy of thirteen

carrying one end of the tape-line. About August 1, surveys and plans being

completed, work was commenced on excavations for the foundations of the

wheel-pit, and on a branch canal,

25 feet wide, which was to be the feeder or race-way to the water-wheels, and

also the route for boats to bring material to the works. The excavation was

under the charge of Robert McIntyre and William Paul. A little later, the

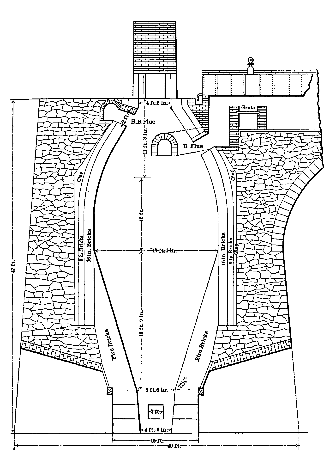

hot-blasts and furnace-foundations were commenced; the furnace being some 30

feet square at the base, 12 feet bosh, and 45 feet high. lines are shown in

Fig. 2. All the masonry was laid by Isaac McHose, Sr., of Rittersville, whose

son Samuel was subsequently the builder of nearly all the furnaces in the

Lehigh Valley. The hot-blasts, with the usual bed-pipes, consisted of four

ovens of 12 arched pipes each, 5 inches interior diameter, 1-1/2 inches thick in the legs and 2 inches

thick in the arch. They were built on the ground and fired with coal, having

deep closed ash-pits, into which blast was introduced for active combustion, in

lieu of a draft-stack. The arch-pipes were not connected with the nozzles on

the bed-pipes by a socket and rust joint, as in later years. The joints were

made with liquid cast-iron, the point of junction on the arch-pipes and nozzles

on bed-pipes being carefully fluted to prevent the iron from running into the

bed-pipes. A pattern in three parts one inch thick, corresponding to a socket,

was placed against the pipe and nozzle with sand packed around it, and when

drawn out left a space into which the iron was poured. On the side of two

pieces of the pattern was a hub in which was placed a core of the depth of the

socket, for the purpose of driving a steel pin, to split it in renewal of

pipes. Melting the iron was done in a small movable cupola placed at the end of

the ovens and blown by hand with a very large blacksmith bellows; and the

melted iron was carried in small hand-ladles to pour the joints. After the

joints were made, they were deluged with salt and sal-ammoniac water, which

rusted them perfectly tight. This plan was followed for several years. There

were diaphragms in the bed-pipes, diverting the blast through three pipes from

side to side; and, with good firing-, a temperature of 600 deg was easily

obtained; but, generally speaking - that was not maintained The elevator for

filling the furnace, called "a water-balance" consisted of two square

boxes of sufficient size, one on each end of a chain, passing over a large

wheel with a brake; a sufficient amount of water being admitted into the. boxes

on top to bring up a load on the other side, while the water escaped out of the

boxes automatically at the bottom. No. 1 furnace was blown by a breast-wheel 12

feet in diameter and 24 feet long; the fall of 8 feet between the canal levels

at lock 36 furnishing the power. On each end of the wheel were segments on its

circumference, of 10-inch face, geared into pinions on double cranks, these

driving two blowing-cylinders having 5 ft. diameter and 6-ft. stroke, with

parallel motion, and worked by beams on gallows-frames. The beams were

constructed of two pieces each of white-oak timber, 14 by 16 in. in the center,

and tapering towards the ends; the beams being also trussed with 1-1/2-inch

rods. The center-shaft of cast-iron, with extension plate and flanged, was

fitted between the timbers; and at the end heavy cast-iron spade-handles were also

fitted between the timbers, for coupling the connecting-rods and links, all

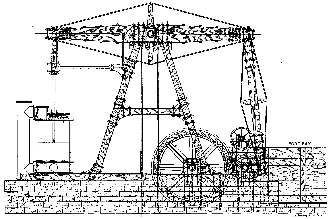

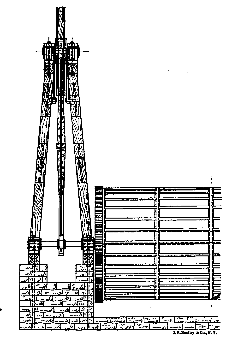

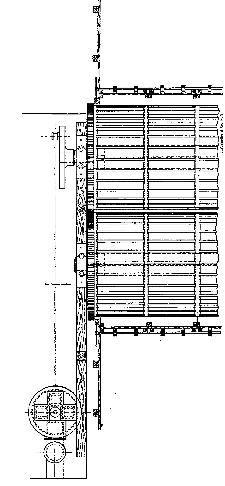

firmly bolted together, as shown in Figs. 3, 4 and 5. The blast from the

cylinders was conducted underneath the canal through an 18-inch cast-iron pipe;

this being the only receiver, the strokes of the cylinders could be counted at

the furnace-tier as easily as in the wheel-house. (The wheel-wrights who did

the work were "Squire" George Frederick, with his sons, Thomas and

Nathan, Edward Scherer, Thomas Barber, and John Leibert, father of Owen and

Henry, now at the Bethlehem Steel Works). About mid-summer of 1839, such

portions of the outfit for this furnace as had been constructed on the other

side of the Atlantic were shipped (Some castings being made here later on),

except the two blowing-cylinders, which the hatches of the ship were too small

to admit. The vessel was also laden with rails for the Lehigh Coal and

Navigation Co., and cleared for Philadelphia; but, having sprung a leak, she

put into Norfolk, Va., in distress, after having jettisoned about 300 tons of

the rails. On receipt of this news, Mr. Hazard and my father went to Norfolk

and, to their consternation, found the cylinders were not there; the captain

telling them, in language more forcible than elegant, that if the castings in

the hold had not been so heavy they would have gone overboard also. After

necessary repairs, the vessel proceeded to Philadelphia; and thence all the

material for the furnace was shipped by canal to the works. Steps were taken at

once to procure cylinders. Application was made to Alger at Boston; the Allaire

works, and the Morgan iron-works of New York; but they all declined to

undertake the work, as they could not bore cylinders of that size, and would

not enlarge their mills for the purpose.

FIG. 2. Furnace No. 1,

Built at Catasauqua, Pa., 1839-40.

At

this time there was not a boring-mill in the United States large enough to bore

a cylinder of. 60 inches diameter; but American progress in the construction of

machinery was so rapid that in 1851 the I. P. Morris Co. of Phila., Pa., made

four cylinders for Ericsson's hot-air ship of 168 inches diameter and 6 feet

stroke.

Fig 3. Water-Power Blowing Engine, Crane

Iron-Works, Catasauqua, Pa. Erected 1839-40. Vertical Longitudinal Section.

Scale: 1/8-in = 1 ft.

Application

was then made to Merrick & Towne of the Southwark foundry, Philadelphia,

who agreed to undertake the work, enlarging their boring-mill for the purpose,

and succeeded in making two very fair cylinders, for which 12-1/2 cents per

pound was paid.

Fig 4,. Vertical Cross-Section of Fig. 3. Scale: 1/8 in.. = l ft..

These cylinders were bored by Harry Smith, who fitted them to

the tops and bottoms sent from England and subsequently erected them in place.

The original cylinders, which had been so unceremoniously left on the docks at

Cardiff, finally arrived at their destination in 1840. They were unloaded at

lock 36, and one of them figured in the great flood of 1841, being rolled by

the water a quarter of a mile down to Biery's bridge, where it lodged in a deep

gully.

Fig. 5 Plan of

Blowing-Engine, Fig 3. Scale: 1/8 in. = 1 ft.

Later,

these cylinders were used in the construction of two blowing engines, which

were erected back of No. 1 furnace. They were in use there several years, and

were then taken down, to make room for the present railroad back of the

furnace. About 1866, the Lockridge Iron Co. was organized at Alburtis. I

purchased these engines and erected them at the first furnace built there. The

Lockridge Co. was later merged into the Thomas Iron Co., and these historical

cylinders are in use by the latter Co. to-day.

After

this long digression, I return to the history of the construction of the works.

That all beginnings are hard, was never better illustrated than in this

instance. Delays, difficulties and discouragements sprang up on every side, not

least among which was the second serious illness of my father, keeping him

housed during weeks in the autumn and greatly impeding the progress of the

work, which he directed as best he could, using me as messenger to those in

charge. The want of foundry facilities was one of the greatest difficulties

encountered; but finally the large cast-iron centerpieces, segments, gudgeons

and pinions for the water-wheel were made at the Allentown Foundry, owned by

George Brobst and Stephen Barber. It was at their foundry that the first

steam-engine in Lehigh county was erected. It is preserved as a curiosity on

the campus of Lafayette College at Easton, Pa.

After

many vexatious delays, the furnace was completed and successfully blown in at 5

o'clock P. M. July 3, 1840, and the first cast of about 4 tons of iron was made

on the memorable 4th of July of that year, the keepers in charge of the furnace

being William Phillips and Evan Jones.

Looking

back on those primitive times, I recall things which, done to-day, would seem

ridiculous. For example, to prepare a furnace for blowing-in, a process called

"scaffolding" the furnace was performed. The front or neck of the

hearth was open, without the dam-plates. Across the knees of the buck staves

was thrown a bar of iron; and, over this and under the tymp, long heavy bars

called ringers

were driven several feet into the material in front, these bars holding it up,

while below, all the clinkers and ashes that could be reached were shoveled and

scraped out of the furnace; the dam-plate and harp were then put in place, and

the bars were drawn out, allowing the front to fill up with fresh live coal.

The plate called the harp was a long tapered plate with teeth like that of a

saw, fastened against the dam-plate, and used to hold up the cinder-fall. The

distance between the dam-plate and the tymp was about 24 inches. The

blast-pressure being so light it was not necessary to hold the plate down with

props under the mantel, as in later years.

During

the construction of the works, mines necessarily had to be opened for the

supply of iron-ore. The first of these wag Rice's mine, near Schoenersville,

Hanover township. The first load of ore brought to the works was hauled from

that mine by Henry Hoch. In the same neighborhood Goetz's and Daniel's mines

were opened, and others in North and South Whitehall townships. The magnetic

ore came from the Irondale, Byram and Dickerson mines in New Jersey, small lots

being purchased from each place and shipped by the Morris canal. The proportion

of ores generally used was one-fourth magnetic and three-fourths hematite. The

furnace remained in blast until its fires were quenched by the rising- waters

of the Great flood of January, 1841, a period of six months, during which 1080

tons of pig-iron were produced. The largest output for one week was 52 tons.

Concerning the flood which I have mentioned, one of the Company's old books

contains the following in my father's handwriting:

"On

Thursday, January 7 (1841), at 9 o'clock in the evening, the river rose so that

the back-water prevented the wheel from turning; at half after 10 covering the

tow-path of the level above Lock 36. At 12 it was 2 feet over the banks and 1

foot over the bottom of the hearth of the furnaces. At 1:20 the water was at

its height, and 34 inches in the furnace, It was at this height until 3.30

o'clock, when the river began to fall. The water-wheel was muddied all over,

and the water lay 9 inches over its top. The dam and canal-bank were broken, so

that when the water fell in the river it was too low to turn the wheel, though

every effort was made to fill up the banks, with no good result, and we were

obliged to throw out (shovel) the furnace on Monday, the 11th of January.

"DAVID THOMAS,

THOMAS S. YOUNG (Bookkeeper)."

Furnace

No. 1 was blown in again after the freshet, May 18, 1841, and then remained in

blast until August 6, 1842, producing 3,316 tons of pig-iron. My father had

been very generally looked upon as visionary. The remark made by a leading

charcoal-iron master, whom I well knew, "1 will eat all the iron you make

with anthracite," gave expression to the general sentiment of the trade at

that time. It is needless to say that he did not keep his promise, although my

father cordially invited him to a hearty dinner, cooked in the company's first

furnace.

After

the success of this furnace bad been fully established, anthracite-furnaces

began to multiply rapidly; Post built at Stanhope, N. J., Henry at Scranton,

Firmstone at Glendon, Governor Porter at Harrisburg, Dr. Eckert at Reading; and

by 1846 there were about 40 anthracite-furnaces in the country, distributed on

the Lehigh, Hudson, Schuylkill and Susquehanna rivers.

In

the latter part of 1841 the Crane company determined to build No. 2 furnace,

and preparations were made accordingly. The furnace was built in the summer of

1842, and blown-in in November of the same year. It was 34 ft. at the base, 13

ft. 4 in. bosh, and 45 ft. high. The lines are shown in Fig. 6. The hot-blast

was placed on top, additional space being provided by making the back of the

furnace vertical for 25 feet, instead of giving it the usual batter. All the

masonry, both brick and stone, was laid by David Walters, who had previously

built a furnace at Farrandsville, Pa. (He was a most excellent mechanic, with

peculiar ideas of his own: for instance, he prevailed on my father to allow him

to put in the lining-brick of No. 2 furnace in spiral instead of horizontal

lines; and inasmuch as one way was about as good as the other, my father gave

his consent.)

The

blowing-apparatus for this furnace bad 2 horizontal cylinders of 5-ft. diameter

and 6-ft. stroke, driven by 2 Fourneyron turbines of 8-ft. outside diameter and

15-in. depth of bucket. On the upper end of the turbine-shafts was a 30-in.

pinion geared into a heavy horizontal cog-wheel of 8-ft. diameter and 10-in.

face, in which were inserted the crank-pins, and to these were coupled the

necessary connecting-rods and cross-heads to drive the cylinders. Each machine

was separate and was operated independently. All this machinery was made by

Merrick & Towne, Southwark Foundry, Philadelphia. The blast was conducted

to No. 2 furnace through the same pipe, under the canal, as to No. 1. The

turbines proving great consumers of water, it became necessary to construct

another canal as a feeder; the current in the old canal being so great that it

was almost impossible to tow a heavily-loaded boat against it, so that the

water on the water-wheels frequently had to be checked, to permit boats to

pass, through. A large force of men under Samuel Glace was put on the

construction of the second canal, which was located on the south side of the

old canal, and completed in four months. The canal is therefore double at

Catasauqua - a fact which has excited the curiosity of many. To protect it

against floods, a cinder-bank was deposited on the outside, and upon this the

Lehigh & Susquehanna Railroad is now laid, from the guard-lock at Hartman

dam to Catasauqua station.

Fig 6. Furnace No. 2, Built at Catasauqua,

Pa, in 1842

In

1843 an experiment was tried at this furnace-the first, I think, of the kind in

this country-with the aim of utilizing the waste-gases for refining iron,

taking out the gas at a depth of some 9 ft. below the top of the furnace.

Previously the gases used for steam and hot-blasts had been taken out

immediately under the dumping-ring at the tunnel-head. The practical purpose of

the experiment was the refining, and puddling of iron for making an extra

quality of bar-iron and wire. I quote from the furnace charging-book the

following in my father's handwriting, under date of October 23, 1843:

"On

Monday night at 12 o'clock the blast was stopped on the furnace to build up

gas-flues; there was 11-1/2 inches of the backing of the furnace taken out,

which was all calcined into lime." (The masonry of the furnace was

limestone.) " The blast was put on again Saturday morning, October 28th,

at 1 o'clock in the morning."

The

construction of this refinery was very similar to that of a puddling-furnace.

The gas was brought down through a conduit built of brick against the side of

the furnace and conducted into one end of the refinery, passing over a

bridge-wall into the body of the refining-furnace, which was built in a

circular form, and on one side of which were inserted two tuyeres at an angle,

to deliver the blast into the molten iron. Immediately back of the bridge-wall

there were some 10 or 12 1-in. pipes, contracted at the tips, through which

hot-blast was blown into the gas as it passed over the bridge-wall. So long as

the material which went into the furnace was dry, the gases came down at a high

temperature, and the heat was intense and melted the iron very readily. After a

rain, however, the wet material going into the furnace so reduced the

temperature of the gases in the flues that it was insufficient to melt the

iron. When successful beats were made, the metal was tapped into iron-chills

about 3 ft. wide and 8 or 10 ft. long, making a plate 1 or 2 in. thick; and as

soon as the iron was set it was deluged with water and broken up for shipment.

Owing to the irregularity of the temperature of the gas, however, not more than

50 tons of metal were made in the six weeks of trial, and the experiment was

abandoned as unprofitable. It was tried under the supervision of C. E. Detmold,

an eminent engineer from Lippe-Detmold, Germany, a most genial man, Of broad

education and intellectual resources, whose name is associated with various

important works and surveys in this country, among others the laying of the

foundation of Fort Sumter, of historic memory. (Mr. Detmold was, at this time,

the agent of Faber du Faur, inventor of the method of utilizing the waste gases

of blast-furnaces.). He assigned to superintend this experiment young Edward S.

Renwick, of the distinguished family of architects and mechanical engineers of that

name, who, with his brother, subsequently built and owned a blast-furnace at

South Wilkesbarre, Pa.

In

1844 the blowing-apparatus was reconstructed. As the blast to both furnaces was

blown in common, the turbine-wheel proved so much more powerful that we could

not get the necessary service from the breast-wheel. So the pinion and the

double crank were abandoned, and the forebay to the first breast-wheel was

shortened 8 ft., moving the wheel forward, which brought the center of the

wheel directly under the point of the beam. We replaced the original gudgeon

with one of 14-inch diameter, on which the crank-wheel was placed, connecting

it with the original connecting-rod. To this was added another wheel, the same

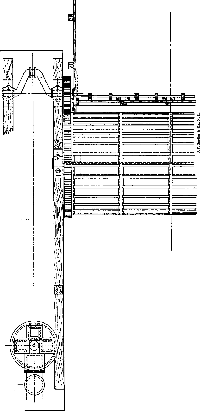

as the first, and they were geared together as shown in Figs. 7, 8, and 9. This

gave us a blowing-apparatus fully equal to the turbine.

In 1845 it was determined to build No. 3

furnace; and the question at once came up, what power should be used for

blowing. I well remember a consultation held on this subject at the Catasauqua

office by Messrs. White, Hazard, E. A. Douglas, Engineer-in-Chief of the Lehigh

Coal and Navigation Co., and my father. Mr. Whine was a great stickler for

water-power, and almost insisted upon its being used. Mr. Hazard and my father

were in favor of using steam-power, maintaining that there was not water enough

in the Lehigh during the dry season to blow an additional furnace. The

discussion grew quite earnest, and Mr. White somewhat impatiently said to my

father, "David, thee does not know what thee is talking about;" but

as Hazard and Douglas coincided with my father, steam-power carried the day.

Fig 7 Blowing Engines for Furnaces Nos. 1

and 2, as reconstructed in 1844.

Scale: 1/8 in. = 1 ft.

No.

3 furnace (see Fig. 10) was 40 ft. wide at the base, 17 ft. in bosh-diameter,

and 47 ft. high, and was fitted with a water balance, like the other furnaces. It

was blown by a pair of beam-engines connected with a single fly-wheel; the

blowing cylinder was 5-1 ft. in diameter and 6-ft. stroke; the steam cylinders

had 26-in. diameter and 6-ft. stroke, with slide-valve and a cutoff. A pressure

of about 6 lbs. could be maintained, and with that the furnace did fairly well.

These engines were built, at the Allaire works, New York, and a Mr. Smith was

the engineer in charge of construction.

Fig. 8. Vertical

Cross-Section of Fig. 7. Scale: 1in. = 1 ft.

Fig. 9 Plan of Fig. 7, Scale: 1/8 in. = 1 ft.

Furnace No. 3, Built at

Catasauqua, Pa., in 1845-6.

In

1847 an experiment was tried at this furnace by passing a strong current of electricity

through the molten iron, the battery for which consisted of 100 cells, very

powerful and dangerous to handle. A heavy iron bar, with a heavy wire attached,

was placed in the runner at the end of the casting-trough, and a second wire

and bar were attached at the extreme lower end of the pig-bed, the current

being maintained while the iron was flowing and for twenty minutes after the

iron was set. This was carried on through some half a dozen casts; but the men

became very shy of the wires, because Jimmy Hunter, the keeper, was knocked

almost senseless by using, an iron bar he held in his band to remove one of the

wires which was in his way. Consequently the experiment was tried in another

way. A bar of iron was suspended from the top of the furnace down into the

material to a depth of some 10 or 12 feet; to this one wire was attached, and

the other to one of the tuyere pipes. The current was kept up continuously for

two weeks. The samples of iron produced in this experiment were puddled, with

the idea that the electric current would be found to have dispelled the

phosphorus; but the results showed no apparent difference from the iron

otherwise made.

At

this time, the steam-whistle was an unknown sound in the Lehigh Valley. I had

secretly had made by Lehman, Sr., a brass-founder of Bethlehem, a large

whistle, which measured 8 in. in diameter, and about 1.5 in. in depth of bell;

and when No. 3 was ready, and the whistle had been attached to the boilers and

they were ready to be tested, and the pressure was up to 60 or 70 pounds, I let

her off." The noise startled the whole town and occasioned much laughter.

Mrs. Noah Davis used to tell how she and the women on upper Church street

rushed out of their houses to gather up their children, thinking, as they heard

the unusual sound, that it was the last trump.

During

1849-50 the Crane Co. built furnaces Nos. 4 and 5, 18 ft. in bosh-diameter and

45 ft. high. To drive these furnaces the most powerful blowing-engine in the

country was erected, with blowing-cylinders 7 ft. and steam-cylinders 34 in. in

diameter (high pressure) and 9 ft. stroke, which would exert with ease a

blast-pressure of 8 to 10 lbs. per sq. in. With the volume of air that could be

delivered, the furnaces were too low to do as well as was expected; so they

were raised to 55 ft. high in 1852, after which the production ranged from 250

to 300 tons each per week. Figs. 2, 6 and 10, showing the lines of furnaces

Nos. 1, 2 and 3 of the Crane Co., were traced from sketches found among the

papers of the late Joshua Hunt, who was connected with the works from 1843 to

1885. The flue shown in No 1 was not used until the hot-blast was erected on

top in 1843. The section of arch shown in No. 2 was built between Nos. 1 and 2

and boilers placed on top when the two engines before mentioned were erected

back of No. 1 in 1850, after which the breast-wheels were abandoned and only

turbines were used, and these only up to 1858, when steam-power was resorted to

exclusively. No. 3 as shown was built with one pier and two arches, one arch

against No. 2, the other against No. 3, on which the boilers and hot-blast were

placed.

As

my friend of nearly half a century's standing, Mr.. John Fritz, of Bethlehem,

truly says in his reminiscences of the pioneer days of iron-making in this

country, the active managers of the iron-works of today, possessed of all the

facilities of telegraph, telephone and railroads, know little of the trials and

tribulations of those arduous early times. It required three whole days to

transact business between us and Philadelphia - two days to go and return by

stage, and one to attend to business. When the roads were bad, it often took us

twelve hours to reach the city.

Up

to 1855 our only means of transportation for coal from Mauch Chunk, and

magnetic ore from New Jersey, was the canal. The hematite ores and limestone

were brought to the works entirely by wagon, the country literally swarming

with teams. We paid in some instances as high as $2.00 per ton for

transportation on some of these ores; and not until 1855, when the Lehigh

Valley railroad was opened, and 1857, when the Catasauqua and Foglesville line

was partly finished, did we begin to have a taste of the labor-saving,

facilities so generally enjoyed today. An immense amount of labor was required

simply to pile up a sufficient amount of coal to run five furnaces during the

four winter months. The unloading of the coal was all done by wheelbarrows; and

the accumulation of our provision commenced in the spring, as soon as

navigation was opened, and continued until the canal was closed, since we had

to store not less than 40,000 tons, in addition to what the furnaces were

continually consuming.. In 1847, with a view of expediting this work, we

erected a large amount of trestling 25 ft. high, and a water-balance near No. 3

furnace, so that the coal could be unloaded into cars, elevated, and then

dumped in this trestle-work. The first season's experience with this system was

not encouraging. The rains and snows of winter caused the coal to freeze; and

it would come down in great masses, often breaking the legs of the trestles and

crushing the coal, making much waste. After the second season the labor-saving

apparatus was abandoned and the wheelbarrow was again resorted to.

As

already remarked, on leaving home I had not the least idea of presenting this

paper before the Institute; but this providential opportunity being offered I

gladly embrace it, desiring to correct certain misapprehensions and wrong

impressions concerning the great discovery in question, and feeling it my duty

to establish, even at this late day, the claims of my father to the successful

application of the use of anthracite in the production of pig-iron. The facts

given I have from my father's own lips. That he did not assert himself more

emphatically at the time was due to his modesty and to lack of means and

influence to obtain a patent, which was no small undertaking at that time in

Great Britain. Mr. Crane has often received the credit of this useful

discovery. With all due respect to his memory, I must state that he was in no

sense of the word a mechanic or a technical man, but a shrewd business man,

with a faculty for recognizing the merits and promoting, the commercial

utilization of the inventions of others - a faculty, by the way, which is as

essential to industrial progress as the genius of the investigator and

inventor.

Josiah

White's son-in-law, Richard Richardson, in his history of the early development

of the Lehigh Coal and Mine Co. (afterwards changed to the Lehigh Coal and

Navigation Co.), refers to the building of the first furnace by my father for

the Lehigh Crane Iron Co. He gives the history of Mr. Hazard's trip to Wales to

inquire into the results at Yniscedwyn and says:

"Mr.

Hazard ordered such machinery as was necessary to be made for the company,

under the direction of George Crane the inventor, and engaged David Thomas, who

was familiar with the process, to take charge of the erection of the works for

the manufacture of iron, and to his faithful and intelligent management much of

the success of the enterprise was due."

It

is not reasonable to suppose that Mr. Hazard, an entire stranger to the

business, should have taken the responsibility of procuring the necessary

machinery and other appliances for the erection of this furnace. The real facts

are, that the whole matter was placed in my father's hands, and that, during

the four months he remained in Wales after the signing of the contract with Mr.

Hazard, he made all arrangements for the entire outfit of the furnace. The

blowing-machinery was constructed at the Soho Works, England, and the

hot-blasts at Yniscedwyn from the same patterns as used there, under the

supervision of John Clee, the assistant superintendent, who succeeded my father

in the management of the works, while the fire-brick came from the Stourbridge

works, England.

Mr.

Swank, the author of that invaluable work, Iron in all Ages, commenting upon

Mr. Richardson's version, says: "We do not hesitate to say that to Mr.

Thomas' management was due the whole of the success of the anthracite-furnaces

built by the Lehigh Crane works." Mr. William Firmstone, another eminent

authority, says: "With the erection of this furnace commenced the era of

higher and larger furnaces and better blast. machinery, with the consequent

improvement in the yield and quality of iron produced." It has never been

claimed that no anthracite pig-iron had been made in this country previous to

1840, but only that the commercial success of this manufacture dated from my

father's work at Yniscedwyn in 1837 and at the Crane works, Catasauqua, Pa., in

1840. I have the highest authority for the statement that not so much as 500

tons of anthracite pig-iron were made in this country during the entire

experimental period preceding 1840.

Having

long felt that a clear statement of the above facts was a tribute that I owed

to my venerated father, the first president of the American Institute of Mining

Engineers, I have to the best of my ability now discharged this duty Thanking

you for your kind attention and patience, which I fear I have greatly taxed - such

being the inevitable result of the host of recollections which rush upon my

memory as I attempt to relate the early experiences of a career of nearly sixty

years in this special work - I close with the lines of the poet Saxe:

"My growing talk of

olden times,

My growing thirst for

early news,

My growing apathy to

rhymes,

My growing love of easy

shoes,

My growing hate of

crowds and noise,

My growing fear of

taking cold,

All whisper in the

plainest voice,

I'm growing old." .

Return

to the David Thomas Biography Page

About

The Hopkin Thomas Project

Rev. August 2010