THE

RED DRAGON

The

National Magazine of Wales.

EDITED

BY CHARLES WILKINS.

VOL. IV.--JULY TO DECEMBER, 1883.

CARDIFF:

DANIEL

OWEN AND COMPANY.

1883.

NOTABLE

MEN OF WALES.

DAVID THOMAS.

THE FATHER OF THE ANTHRACITE IRON TRADE.

Ed.

Roberts, Westfield, Neath 1882

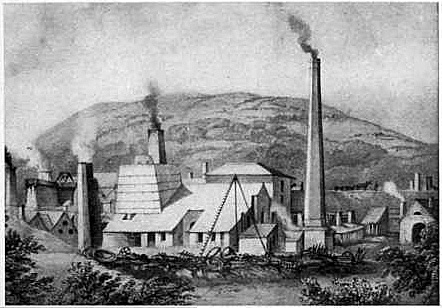

View

of Yniscedwyn Iron Works near Swansea, South Wales

Anthracite iron,

except to some engaged in the metal trades of South Wales, is a term,

comparatively speaking, unknown to the general public in this country as having

any distinctive feature apart from any other iron. The term, however, is

applied to iron made with anthracite iron coal -- the purest fuel ordinarily

used in the manufacture of iron, which is produced in the western portion of

the South Wales coalfield, extending from the upper part of the Vale of Neath,

in Glamorganshire, on the east, to Saundersfoot, in Pembrokeshire, on the west.

At the Yniscedwyn Anthracite Iron Works, in the Swansea Valley, there is almost

an inexhaustible supply of this invaluable fuel -- one seam, the four feet, is

especially considered and confirmed by experience to be the very best for

smelting purposes, on account of its purity and strength under burden in the

blast furnaces, and it proves there to be of the most superior quality, and is

unequalled by any other coal for iron making. Some few years after the

departure of Mr. David Thomas from Yniscedwyn to America, a sample of this seam

was sent to Dr. Percy, of the Metallurgical School of Mines, London, for

analysis, and he found it to contain a higher percentage of carbon than any

other coal in Great Britain, absolutely smokeless, perfectly free from sulphur,

and to contain a minimum of waste matter. Indeed, Anthracite Coal may not

inaptly be described as Nature's Coke, and, in confirmation of what is stated

above, I find in the official report just issued of the tests made at South

Kensington last year by Mr. D.R.Clark, C.E., on behalf of the Committee of the

Smoke Abatement Society, London, that the anthracite coal from the Yniscedwyn

Coalfield ranked first both for domestic and steam generating purposes, as

compared with other coals, whether anthracite, steam, or bituminous. It has

also the great advantage of entire freedom from smoke. This purity in the fuel,

no doubt, has its effect upon the quality of the iron, as the Yniscedwyn Brand,

known as "Crane Anthracite Iron", has since the days of Mr. Thomas'

management there stood pre-eminent in the metal market for toughness,

ductibility, and strength; and, in consequence, it has been largely used for

charcoal tin-plates, charcoal wire, horsenail rods &c. Some ten years ago,

the writer saw iron made at Yniscedwyn under the furnace management of Mr.

Thomas Clee, -- undoubtedly one of the foremost anthracite iron smelters in

South Wales, -- which, on being submitted to the rigid series og trials by Mr.

Kirkaldy, at his Testing Works, Southwark, showed the tensile strain to average

22,000 lbs. per square inch; and under a thrusting strain, pieces about one

inch and an eighth of an inch in diameter, and eight inches long, deflected

three-eighths of an inch before showing any signs of fracture. I have before me

a tabulated statement, shewing the yields of several "Brands" of Pig

Iron as tested some few years ago at one of the principal Tinplate Works in

South Wales, and, selecting two of them, I give below the results obtained, as

between "Anthracite" and "Barrow Hematite" No. 3 Pig Iron,

viz.:--

|

|

Pigs delivered. |

|

Stamps produced. |

|

Loss in conversion. |

||||||

|

|

cwts. |

qrs. |

lbs. |

|

cwts. |

qrs. |

lbs. |

|

cwts. |

qrs. |

lbs. |

|

Anthracite |

6 |

0 |

14 |

...... |

5 |

0 |

14 |

...... |

1 |

0 |

10 |

|

Barrow Hematite |

6 |

0 |

24 |

...... |

4 |

0 |

2 |

...... |

2 |

0 |

23 |

Equal in the case of

Anthracite Iron to 17.5 per cent., and in the case of Barrow Hematite to 35.0

per cent loss. The blast furnaces built by Mr. Thomas at Yniscedwyn have all

disappeared and been superseded by others of more modern construction, both as

regards enlargement and improved appliances, and hot blast arrangements -- the

outcome of various experiments and experiences resulting in almost a maximum of

production.

I offer no apology

for prefacing the foregoing specific, and, I hope, not uninteresting facts, as

to my mind they are simply the sequel, or, might I rather say, the results of

the development of the foundations laid some fifty years ago at Yniscedwyn, the

scene of the early struggles, labours, hopes, fears, aspirations, experiments,

failures, and successes of the eminent man who forms the subject of the

following biographical sketch, and where his memory is still held in the

highest estimation by the oldest inhabitants of the place. It is to him belongs

the high honour of having made at Yniscedwyn the first anthracite iron ever

cast in Great Britain, or, indeed, in the world; and in America he is justly

and proudly recognised as the Father of the Anthracite Iron Trade of

Pennsylvania. Mr. Thomas' life and successes with the Anthracite Iron Trade in

America are well-known in that country, but as they may not possibly be so

well-known as they deserve to be amongst his countrymen generally in Wales, I

have thought it well to cull from various sources, and to put together the

principal incidents of so interesting and instructive a career.

Mr. David Thomas

was the son of David and Jane Thomas, of Tyllwyd Farm, in the parish of

Cadoxton-juxta-Neath, in the county of Glamorgan, South Wales. He was one of a

family of four children, one son and three daughters, and was born on the 3rd

of November, 1794. Two of the daughters are still living, one eighty-two years

of age living in the parish of Ystradfellte, within a short distance of Colbren

Junction, on the Neath and Brecon Railway; the other, aged 79 years, lives

within half a mile of Tyllwyd, her birthplace. In an interview with the latter,

the writer could not fail being struck with the clearness of her intellect and

memory (which was also a strong characteristic of her brother), tracing events

back as far as sixty years ago. David Thomas, the father, was a small farmer,

but a highly respectable man in his parish, and although a Dissenter, he held

the office of churchwarden for some years, and was overseer of the poor of his

parish for sixteen years. He was a consistent and exemplary member of the

"Independents" Religious Community at Maesyrhaf Chapel, Neath for

forty years, and his wife, who survived him twenty years, was one for some

sixty years. Both are buried in the burying ground attached to the above-named

place of worship. Young David's religious and moral training was, therefore, of

the strictest kind, both as regards example and teaching, and these appear to

have clung to him through life. Being the only son, his parents were anxious to

give him the best education their means would allow, and that the district

afforded. In the first instance he attended a school at Alltwen, Pontardawe,

where he appears to have made such progress that at nine years of age he was

removed to a more advanced one at Neath, and the best then in the district, his

father paying one guinea a quarter, which was considered a large amount in

those remote days. In this school he applied himself with industry and

perseverance, outstripping all his schoolfellows, and was looked upon as having

been better educated than the generality of the neighbouring farmers' sons. He

was of very studious habits, delighted in books and in acquiring knowledge and

information, and was determined to get on. The education, however, he received

enabled him only to acquire the merest elements of learning; the intelligence

and knowledge displayed by him in after life, which enabled him to rise to so

prominent a position, were due entirely to self culture. His father's holding

was not a large one, and, as is generally the case with Welsh farmers, all the

members of the family in their turn has to assist in the operations on the

farm. In this capacity young David was employed for some time; but agricultural

pursuits were not to his taste, and he could not be made to settle down to this

class of occupation. His thirst for knowledge and improvement had awakened in

him an ambitious feeling which farming operations failed to satisfy; and in

1812, at seventeen years of age, he determined to branch out in a line of life

which he thought presented more prospects then working on a small farm; and he

consequently went to work at the Neath Abbey Iron Works. For five years he

worked in the fitting shop and at the blast furnaces there, asserting his

superiority and intelligence over his young com-peers, by whom he was

familiarly known as "Dai Tyllwyd,"

by showing a wonderful aptitude for the business, and gaining a vast store of

experience and knowledge, even in that short space of time. In fact, so well

did he occupy his time and talents, that in 1817 he went to Yniscedwyn

Anthracite Iron Works, in the |Swansea Valley, then owned by Mr. Richard

Parsons, where he was made general superintendent of the blast furnaces and of

the iron and coal mines. There he was known as "Dafydd Thomas y Stiwart," by which name he is also spoken of even now by

the oldest inhabitants of that place -- a somewhat more dignified title than

that of the homely one of "Dai Tyllwyd," in vogue at the Neath Abbey Iron Works. Mr.

Thomas remained at the Yniscedwyn Works in that position for nearly twenty-two

years, working his furnaces in the most successful manner, and continually

experimenting with anthracite coal as a smelting fuel. It so happened that the

Yniscedwyn Works then actually stood alone on the only belt of anthracite coal

in Greate Britain, extending over the district already described; the

argillaceous clay, iron stone, and black band being stratified all the way

through it. And yet, with this bountiful supply of magnificent fuel lying under

their very works, the Yniscedwyn folks were hauling coke to their furnaces from

a distance of fourteen or fifteen miles. Mr. Thomas naturally argued that when

the fuel and ore lay together, as they did there, the fuel must be suitable for

smelting the ore, provided the right process of doing so could be hit upon.

With this aim in view he began as early as the year 1820 to make experiments.

In this same year the Lehigh Coal and Navigation Company in America succeeded,

after much difficulty, in getting 365 tons of their now famous anthracite coal

to Philadelphia; and then they found out, to their horror and disgust, that

they had overstocked the market. People said it would not burn, even that it

put their fires out, and absolutely refused to buy it. But David Thomas knew nothing

about this; all he knew was that a seam of coal lay under his very feet, and

that he was most anxious to utilize it in his blast furnaces, if possible. So

in ignorance of the struggles of the Lehigh Company, and little dreaming that

his road to wealth and position led through this very doorway, he quietly and

persistently went on with his experiments, undaunted by his repeated failures.

Of his various experiments Mr. Thomas used to say :- "As early as 1820 I

had some anthracite coal to put into the furnace with coke, in the proportion

of from one part in twenty to one part in twelve; this did very well; but

whenever anything went wrong with the furnace the fault was always laid on the

coal; and the men became so prejudiced against it that I had to give it up.

Still every year I would try some experiments with it, both in cupolas and

blast furnaces. In 1825 I had a small blast furnace built with a nine foot

bosh, and twenty-five foot stack. After blowing it in with coke, I introduced

anthracite coal, increasing the quantity of it more and more. But the tuyers

would close up, so that we had to abandon it. In 1830 I enlarged the furnace,

giving it an eleven foot bosh and a forty-five foot stack. This resulted in a

greater amount of success. Still the whole thing was so unprofitable that it

was given up."

But while Mr.

Thomas had been so resolutely experimenting, another brain had been scheming,

devising, and, at last, perfecting an invention which was to create a

revolution in blast furnaces, and enable him to reach the goal of his ambition.

That invention was hot blast.

In the year 1828 Mr. Neilson, of Glasgow, Scotland,

began making experiments in this direction, and in 1834 he patented his

valuable invention - the heating of the blast before introducing it into the

furnace. In those days it took a long while for news to reach distant parts of

the country; and it took two years to reach the sharp and eager ears of Mr.

Thomas. By that time the Clyde Iron Works had a hot blast furnace in operation;

and Mr. Thomas hurried off to Scotland to see how the process worked. After the

most careful examination he determined that the new hot blast was just what was

wanted for an anthracite furnace. He returned to Yniscedwyn with a license from

Mr. Neilson, and an expert mechanic who understood the construction of heating

ovens. The furnace was prepared for the new blast, the heating ovens were

attached to it, and on the 5th February, 1837, the furnace was blown in. The

success was complete, and anthracite iron continued to be successfully and

profitably made from that furnace without intermission. Anthracite iron was a

new-born commodity in the commerce of the world, and David Thomas, of

Yniscedwyn, was its godfather. Mr.Thomas was in the habit of telling an

interesting anecdote in connection with his hearing of Mr.Neilson's invention.

It appears he was one evening in the house of Mr.George Crane, a gentleman who

then owned the Yniscedywn Works, and who always burnt anthracite coal in the

grate of his sitting room. Mr.Thomas began to blow the fire with a small pair

of bellows. "Don't do that, David, or you will blow the fire out,"

interposed Mr.Crane. "If the air out of that bellows were only as hot as

Mr.Neilson describes his hot blast to be," rejoined Mr.Thomas, "the

anthracite coal in that grate would burn like pinewood." Mr.Crane

exclaimed "Ah! that is the idea precisely," and this idea both

recognized as one which would bear working out; and through Mr.Thomas'

indomitable pluck and perseverance it succeeded. The writer lived for some

years in the house formerly occupied by Mr.Crane, and he distinctly recollects

this veritable grate, which was of such unique construction that it deserves to

be described. It was built internally with bricks, and in shape about a foot

square, and eight or nine inches high - not tapering at the bottom, like

ordinary modern grates - with vertical bars and cast iron shutters or wings,

which were closed or opened for the regulation of the draught necessary for the

ignition of the coal, and when closed it had the appearance of one solid piece

of a handsome casting. Mr.Crane was a short, little man, quick and energetic in

his actions, and most persevering and pushing in business, and such an

uncompromising strict Sabbatarian that he actually suspended all operations at

the blast furnaces while he held a religious service in the adjoining

carpenter's shop, in which he assembled all his workmen on Sunday afternoon. He

was also rigidly zealous for the due observance of the prohibitory Sunday

drinking hours, and was the terror of all the publicans in the parish of

Ystradgynlais, whose houses, in virtue of the powers vested in him as

churchwarden, it was his habit to visit during Divine service on Sundays. And

many amusing tales are related of him, how, while on his visits, and when

within a short distance of a public house, he would run as fast as his legs

could carry him; with the view, presumably, of suddenly pouncing upon some

unsuspecting Bacchanalians who might easily be cosily quenching their thirst

after the previous Saturday night's carousal; in which case the approach of the

enemy created a terrible consternation, and was the signal for an immediate

rush, a scramble, and a real race, quickened by the well-known agility of

Mr.Crane, and the fears of the consequences of a magisterial fine.

But to revert to

Mr.Thomas. He had lit a candle, which there was no possibility of hiding under

a bushel, even if he wished to do so. The wonderful success of the application

of hot blast at Yniscedwyn spread about like wild-fire amongst the neighbouring

ironmasters, and Mr. Joseph Price, of the Neath Abbey Ironworks, applied the

invention to his furnaces at his works there, which Mr. Crane objected to, as

an infringement upon his patent rights. Mr.Price, however, contested the point

on the ground that the application of the patent simply to anthracite coal was

inadequate to sustain the claim. The case was, I believe, carried to the House

of Lords, and it was finally decided that the public utility of the application

to use anthracite was clear, and that, therefore, the patentee was as much

entitled to his rights as such as if he had himself been the original inventor

of the applicability of the hot blast to any purpose whatsoever. Mr.Price did

not stop his defence at this point, but made another and somewhat ingenious

attempt to escape his liability to pay royalty by declaring that he did not

admit that the coal he used for his furnaces, and which he obtained from the

upper part of the Vale of Neath, to be anthracite at all, but

"anthracitous"; but he utterly failed to establish this point. There

were also the owners of the great anthracite coal measures of Pennsylvania

watching like cats at mice-holes for any break in the cloud which seemed to

hang over their fortunes. They, like Mr. Thomas, felt assured that their coal

could be used as blast furnace fuel, if they could only discover the proper

mode of using it. The Lehigh Coal and Navigation Company, whose splendid mines

cluster in the neighbourhood of Mauch Chunk, had spent a large sum of money in

building a blast furnace for the purpose of making experiments with anthracite

coal as fuel. They did actually succeed in making some anthracite iron; but

found the same trouble as Mr.Thomas had with his cold blast - they could not

keep the furnace in blast. They were, therefore, compelled to give it up. But

in the summer of 1838 the London Mining Journal conveyed to them the welcome and cheering news of

Mr.Thomas' great success at Yniscedywn, and in November one of their leading

directors, Mr. Hazard, crossed the ocean to witness the process, and learn all

about it, with authority to bring back with him one conversant with the process

of making anthracite iron. Proceeding at once to Wales, he found the Yniscedwyn

furnaces in full and successful operation. Prior to his arrival Mr.Thomas had

removed to Devynock, distant some twelve miles, to superintend the construction

of a tramway from thence to Yniscedwyn. Mr.Hazard was driven over there by Mr.

Crane, who strongly recommended Mr.Thomas as the only man who could answer his

purpose. The result was that he was offered and accepted a five years'

engagement to go to the United States, and see what he could do with an

anthracite furnace in the Lehigh Valley.

He arrived in America

in June, 1839, but on his arrival in New York he was laid up with fever, and

during his illness poor Mrs.Thomas was in great trouble on account of her

inability to speak a word of English, and consequently she was unable to

understand the directions of her husband's medical attendant. On his recovery

he proceeded to his destination, where, soon after his arrival, the Crane Iron

Company of Catasauqua was organised, and in the following month the

construction of the first of the present six furnaces of the Crane Iron

Company, so called in honour of his patron, Mr.Crane, of Yniscedwyn, was

commenced. It was not a large one. It had only an eleven foot bosh and a

forty-seven foot stack. The first run of iron was made on the 4th of July,

1840, with the most encouraging success; and that furnace ran on steadily for

many years (until it was taken down and the site occupied by the enlarged and

modernised No.1) making, small as it was, compared with the giant furnaces now

in vogue, its one hundred and eighty tons per week with praiseworthy

regularity. In 1841 the company built a second furnace, in 1846 a third, two

more in 1849, and the sixth in 1868, but how many more since I have no means at

my disposal for ascertaining. While Mr.Thomas was quietly making his preparations

and constructing his first furnaces, other experiments were being made with

anthracite coal for fuel. Furnaces were especially constructed for this purpose

in South Easton, Pottsville, Mauch Chunk, and one or two other places. But they

shared the same fate as the previous efforts of Mr.Thomas and of the Lehigh

Coal and Navigation Company. They did make some iron, but they could not keep

their furnaces in blast for any length of time, and all turned out to be

ruinous enterprises. To Mr.Thomas then there is undoubtedly and justly due the

credit of having built the first anthracite blast furnace in America, or any

other country, which successfully fulfilled the purpose for which it was

constructed.

In 1854 the Thomas

Iron Company was formed, and the beautiful works at Hokendauqua commenced,

situated about a mile above Catasauqua, on the Lehigh River, where six furnaces

have been built. In 1855 he relinquished the superintendence of the Crane

Ironworks, being succeeded by his youngest son, Mr.John Thomas, and devoted his

time and interest in developing the works at Hokendauqua, which works bear his

honoured name. In addition to his interest in the Crane and Thomas Ironworks,

Mr. Thomas was also interested in the Carbon Iron Company, which had three furnaces

at Perrysville; and in the large Rolling Mills at Catasauqua and Ferndale,

which produce a quality of iron of high repute. of which he was the president

for many years. A short time before his death he withdrew from very active

duties, remaining, however, a director and a large shareholder, and he was

besides largely interested in collieries and iron ore mines. He was for many

years President of the Catasauqua and Fogelsville Railway, as also of the

Lehigh Railway. He was trustee and executive member of St.Luke's Hospital, and

a trustee of Lafayette College at Easton. In 1866 he was a Republican candidate

for Congress, but declining on principle to take part in the canvass he was not

successful, but made a very complimentary showing. Catasauqua's progress has

been identified with his life, and with almost every industry in the town he

had been connected either as an adviser or an interested party. It is the

outcome of his genius, spirit, determination, and progress, and when it was

incorporated in 1853 he was chosen its first burgess, and continued to hold

office for years, and took an active part in the material prosperity of the

town, and in the religious, educational, and moral welfare of its inhabitants.

In 1840, soon

after his arrival in America, he organised the first Presbyterian Church, and

was an elder of it until his death. He built the Lehigh Fire Brickworks, which

are of considerable dimensions, and held the position of director of the

National Bank of Catasauqua, in which he had a large amount of stock. The

anthracite furnaces number nearly one fourth of the grant total of the blast

furnaces in America, and to them much of the wealth of that country is,

undoubtedly, to be attributed. And the man who has occupied the most prominent

and the proudest position in the records of iron manufacturers was Mr.David

Thomas, of Catasauqua, unquestionably one of the largest ironmasters in the

world. Mr.Thomas was a man of determined purpose, industry, fidelity, and

thoroughness, of uncommon vitality and activity; and although nearly

eighty-eight years of age at his death, he took, nearly to the last, a fair

share in the active management of the vast interest he controlled. He was as

upright and as firm on his legs as a man of sixty, and appeared to possess the

wiry physique and age-defying brain which characterise many of those who live a

generation longer than ordinary mortals. In the transaction of his multifarious

duties he thought as little of going to Philadelphia, New York, or Pittsville,

as he did of walking down to his office in Catasauqua. In February, 1874, he

attended the Ironmasters' Convention in Philadelphia, and was unanimously

elected its President - a graceful and well-earned compliment. At these

meetings his presence was always hailed with pleasure, and his opinions

honoured and appreciated. Indeed, not only in the strength of mind and body,

which was husbanded by a studiously regular habit of "Early to bed and

early to rise," but also in personal appearance it was difficult, whilst

speaking to him, to realise the fact that he was an octogenarian. His successes

in early life were not easily won, especially those for which he will be held

in grateful remembrance by future generations, and he had many obstacles to

overcome, which would have broken the courage of one with less fixedness of

purpose and strength of character. Mr.Thomas had, through his good and

exemplary life, coupled with his venerable and patriarchal age, endeared

himself to all who had the pleasure of his acquaintance far and near, and both

young and old delighted in giving him the respectful and affectionate title of

"Father Thomas," while Mrs.Thomas equally shared in the affectionate

respect shown to her husband, and was addressed as "Mother Thomas."

They had been married for nearly sixty-five years - a very unusual period of

companionship. Their family consisted of David and Gwenny, both of whom died

before their father, Jane, Samuel, who is President of the Thomas' Iron

Company, with numerous grand and great grand children, who used to gather round

the old gentleman and prattle on his knees, making him feel as happy and active

as if he were twenty years of age.

Mr.Thomas was

taken ill on the 20th May, 1882, his illness developing into an attack of

pneumonia, which terminated fatally. His illness was painful, but throughout he

bore his affliction uncomplainingly, and on the evening of the 20th June, 1882

(exactly one month from the day he was taken ill), he quietly and peacefully

breathed his last. Plain in words and manner, his directions about his burial

were of the simplest kind. The corpse was placed in the large hall in the

house, and from one to three o'clock on Friday afternoon, 23rd June, hundreds

of people passed through it to have a farewell view of the mortal remains of

their old dear departed friend and benefactor. It was a sad day for Catasauqua,

and will long be remembered. All works and business in the neighbourhood were

stopped. The funeral service was simple and plain, consisting of the singing of

a hymn, the reading of selections of Scripture from Psalms and Corinthians by

the pastor, prayer by Dr.Catelle, of Lafayette College, Easton, and the

rendering of a favourite hymn -

"My

home is there."

The funeral

procession was the largest ever seen in Catasauqua, and was headed in the

following order :- The employés of the Catasauqua Manufacturing Company, three

hundred men; of the Thomas Iron Company, three hundred men; and those of the

Catasauqua and Fogelsville Railway, and others; then came learned, and wealthy

men from abroad; then the corpse, followed by the relatives and intimate

friends, until Fair View cemetery was reached, wherein, in a vault, were

deposited all that remained of one greatly beloved and respected by his

fellow-men. None but a great man could have commanded such universal respect.

I have been

induced to compile the foregoing sketch of Mr.Thomas' life - and the doing so

has afforded me extreme pleasure - by my great admiration for his noble

character, indomitable courage and perseverance in overcoming difficulties,

coupled with my having been for several years associated with Yniscedywn

Ironworks, where his experiments and successes were made, and which led

eventually to his attaining so prominent a position and world-wide fame as an

iron manfacturer - a character that cannot fail to command the highest

admiration, and one that may worthily be emulated.

"Lives

of great men all remind us

We may make our lives sublime ;

And, departing, leave behind us,

Footprints on the sands of time."

ED.

ROBERTS,

Westfield, Neath.

Keyboarder's notes:

I hope to enhance this with more Internet links as I find them, but without

disturbing the layout, which is as close as I can get to the original document

using html. There is also a charcoal drawing of David Thomas after the title

page - I hope to scan this in to complete the authenticity of this

reproduction.

Some of the spellings have changed a little nowadays because of the tendency

to revert Welsh place spellings to the 'correct' version of pre-Anglicanisation

times. So, Yniscedwyn is now Ynyscedwyn, and Devynock is often shewn as

Defynnog (indicating the correct pronunciation of 'devunnog'). Hyphens are now

commonly introduced to separate the original Welsh words, as in 'Ty-Llwyd' and

Maes-yr-Haf. Ynyscedwyn is still shown on maps unhyphenated.

Researchers may be assisted by noting that the area around Ty-Llwyd is known

as Bryncoch, and had its own Anglican church built (called 'Dyffryn' church

rather than Bryncoch) at the end of the 19th century, so family links with the

original parish church at Cadoxton cease about then.

Ynyscedwyn is an industrial area of Ystradgynlais.