OXMOOR FURNACES

Jefferson

County, near Birmingham

Excerpt from Alabama

Blast Furnaces, Woordward Iron Company, Woodward,

Alabama,1940

SHORTLY after outbreak of the Civil War, the Alabama Arms

Manufacturing Co. was organized for the purpose of mining ore and manufacturing

iron for Confederate ordnance. Incorporators of this company did not have

sufficient capital to develop their mineral property and two of their number were

delegated to petition the Confederate Government for financial aid. A large

portion of the necessary money was advanced by the Confederacy with the

stipulation that the advance be repaid in pig iron.

The Red Mountain Iron and Coal Company, with a capital of

$1,250,000, was incorporated Nov. 5, 1862, "a corporation successor to the

Alabama Arms Manufacturing Co." This new company began erection of two

stone blast furnaces under the direction of Wm. McClane.

Only one of these furnaces was completed and about one year later, in the late

fall of 1863, the first blast furnace of Jefferson County was put into

operation. Shortly afterward, T. M. Brannan became superintendent and Moses

Stroup (of Round Mountain and Tannehill) was put in charge of the charcoal

burning.

Due to the company's contract with the Nitre

and Mining Bureau of the Confederate States, a very large portion of its

product was shipped via the Selma, Rome & Dalton Railroad to the C. S. A.

arsenal at Selma. A certain portion of the output was consigned to the arsenal

at Rome, Ga. Ore for this furnace came from Red Mountain and was hauled by

teams the short distance to the plant. As was common practice in other furnaces

of that time, charcoal from surrounding forests was the fuel used.

The little Oxmoor furnace stood

about 32' high and was 9' or 10' in the bosh. Considering the size of the stack

and the highly siliceous content of the red hematite ore (soft) it is doubtful

whether the daily capacity of the furnace ever exceeded five or six tons. In

order to produce this amount of iron, not less than 60 men were required at the

furnace and between 200 and 300 slaves for cutting and hauling wood for the

charcoal burners.

Early in 1865 Gen. Wilson of the Federal Army concentrated a

force of picked cavalry in North Alabama. The purpose was a series of raids

through Central Alabama to culminate in the capture and destruction of the

Confederate arsenal at Selma. Wilson divided his command and the two divisions

marched by different routes toward the town of Elyton

in Jones Valley. At that place the forces were reunited during the last of

March. Once again Wilson divided his command, Croxton

going south in the direction of Tuscaloosa and Wilson taking the Valley Road to

the east. On March 30 the detachment under Wilson came upon the furnace of the

Red Mountain Iron and Coal Co. and burned all the wooden buildings and

destroyed the machinery.

The plant remained in a wrecked condition until sometime in

1872 when the Eureka Mining and Transportation Co. was organized to take over

the old Red Mountain Company. Daniel Pratt, a wealthy cotton gin manufacturer

from South Alabama, supplied a considerable portion of the capital. The new

company rebuilt the stone furnaces and enlarged them to 60' x 12'. Additional

height was achieved by superimposing upon the stone top an iron cylinder

"with bell and hopper." It was hoped that this enlargement of the

stacks would materially increase the output. The rebuilt furnaces were put into

blast late in 1873 but the anticipated increase in production was not realized,

due mainly to the inexperience of the operators. Though rated at 25 tons a day

each the furnaces but seldom made more than 10 tons each. They were blown in on

a mixture of half charcoal and half coke. Coal was obtained first from the

Helena mines and coked in much the same way that wood was converted to

charcoal, in shallow pits covered with dust.

A narrow gauge railroad of two and one‑half miles was

constructed to the ore mines and ten charcoal ovens of 2500 bu. capacity each

were built at the furnaces to supplement the outside supply. A total of

$200,000 was spent at this time.

The furnaces were operated for only a few months when the

panic of 1873 descended on the iron industry and the plant was shut down.

In 1875 the property was leased by James Thomas and Company which operated the plant for a few months and then

gave it up. (Ed., James Thomas remained

as General Manager until 1879.) During this period the future of the iron

industry in the Birmingham District seemed very dark; the Irondale Furnace had

failed and the Oxmoor plant was idle. At this point a

group of citizens, who had invested heavily in Birmingham real estate on the

strength of its mineral resources, called a meeting with the object of

determining whether Birmingham pig iron could compete successfully in Northern

markets. A collection was taken up and sufficient capital was thus raised to

make an experimental run of iron using coke as fuel. Only three coal mines were operating in Alabama at this time (at

Helena, Warrior and New Castle) and each of them contributed coal. The L &

N Railroad contributed free transportation and some cash, and The Eureka

Company supplied the No. 2 furnace and the red ore. After some alterations to

the stack, the furnace was blown in and on Feb. 28, 1876 the first coke iron

was produced at Oxmoor.

This experiment proved a success and the No. 1 furnace was

rebuilt to use coke and completed in July 1877. Both the furnaces were now iron

shell stacks (No. 1‑60' x 16', No. 2‑60' x 14') but still had

sandstone hearths. With rebuilding of the furnaces, the mines at Helena were

increased in capacity and 100 beehive ovens were constructed there. A small

battery of Belgian coke ovens was also erected at the furnace to coke Cahaba

Coal.

Shortly after the coke iron was made, two groups -- one from

Louisville and the other from Cincinnati -- sought control of the operation.

Neither party was successful and for the next few years the plant was operated to

the dissatisfaction of everyone. David Sinton of Cincinnati finally gained

control in 1886 and operated the property until it was sold on October 18, 1890

to the DeBardeleben Coal and Iron Co. Oxmoor No. 1 had been rebuilt in 1885 and in 1886 the No. 2

furnace was enlarged to the same size as the No. 1, 75' x 17'. The combined

output of the furnaces was thus increased to about 250 tons a day.

On June 1, 1892 the DeBardeleben

Coal and Iron Co. was taken over by the Tennessee Coal, Iron and Railroad Co.

and once again the Oxmoor Furnaces changed hands.

When the United States Steel Corp. acquired the Tennessee Coal, Iron and

Railroad Co. in 1907 the Oxmoor stacks changed

managements for the last time.

Under the old Tennessee Coal, Iron & Railroad Co. these

furnaces had been rebuilt but not enlarged, the No. 1 in 1902 and the No. 2 in

1899. On October 26, 1907 (the year in which they were acquired by the United

States Steel Corp.) the furnaces were blown out and remained idle until

February 21, 1913 when they were relighted. Oxmoor

continued to operate throughout the World War. After the War, however, it was

decided that due to the cost of fuel transportation and the location of the

plant, only one stack should operate, the other being used as an alternate.

The last iron to be made at Oxmoor

was in May 1927. During 1928 both stacks were dismantled. Thus ended the

history of Jefferson County's first blast furnaces‑a colorful history of

64 years.

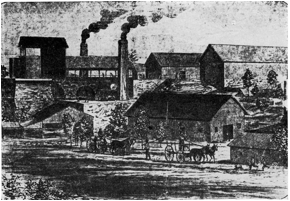

Oxmoor furnaces in 1873 after being rebuilt.

Note cylindrical iron furnace tops on stone bass at left center of this early

woodcut.

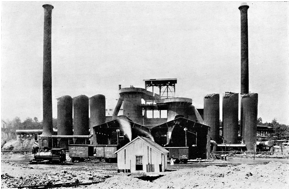

Oxmoor Furnaces Nos. 1 and 2 in 1885 before N. 2 Furnace was

enlarged to same size as No. 1.