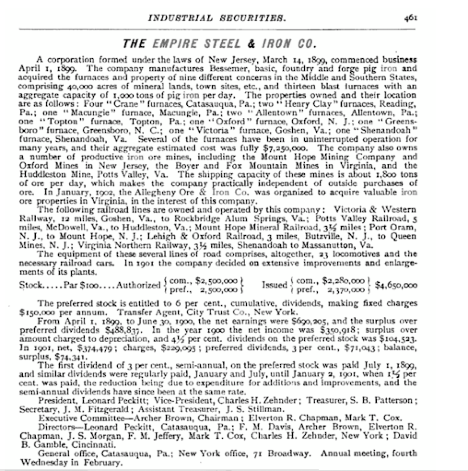

Empire Steel and Iron Co.,

Operators of the Celebrated Crane Iron Works,

CATASAUQUA,PA

Published in Greater America, Vol. 3, January 1900

The

Empire Steel & Iron Co. was incorporated in April, 1899, under the laws of

New Jersey, with authorized capital of $5,000,600, of which $4,6oo,ooo has been

issued. The purpose of the organization was to make foundry, Bessemer, and

forge pig iron.

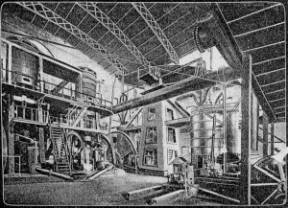

A PAIR OF THE CRANE BLOWING ENGINES

It

has acquired thirteen furnaces, five of which had been in almost continuous

operation during the "seven lean years." Five more have since been

added to the producing column. Of these furnaces, nine are in Pennsylvania, one

in. New Jersey, two in Virginia,

and one in North Carolina. The original cost of the properties

comprising the Empire group was about $7,250,000.

The

official organization of the Empire Steel & Iron Co., is as follows:

President, Leonard Peckitt, of

Catasauqua, Pa., for many years President of the Crane Iron Works.

Vice President, Walter Kennedy, of

Pittsburg. Mr. Kennedy has charge of the engineering.

General Manager and Treasurer, W. L.

Sime, for many years Secretary and Treasurer of the Sloss Iron & Steel Co.,

of Birmingham, Ala.

Secretary; Glen Wright, New York,

Executive Committee, Archer Brown, of

Rogers, Brown & Co.; E. R. Chapman, of Moore & Schley, and W. L. Sime.

Thoroughly experienced men are in charge of the various

divisions as Superintendents.

The central office of the Company is in

the Empire Building, at No. 71 Broadway, New York. The selling agents are

Rogers, Brown & Co., and Rogers, Brown & Warner.

The largest operations of the Empire

Company at any one point are conducted at Catasauqua, where are located four

furnaces, three of which are active and producing 3oo tons per day.

The Crane Brand having been on the

market for sixty years has acquired a well-earned standing, second to none. Its

product is Foundry, Forge, Bessemer and Low Phosphorus Bessemer, made on a

mixture of Lake Superior Hematites and New Jersey Hematites and Magnetites,

with ConnellsviIle coke and Anthracite coal as fuel. The Low Phosphorus

Bessemer is made from a Low Phosphorus ore. One furnace is run continuously on

the "Crane L. P." Brand of Low Phosphorus iron, which commands a

fancy price. The plant is equipped with Laboratory, Foundry and Machine Shop.

Numerous comfortable dwellings for the operatives are located convenient to the plant

The water supply of the City of Catasauqua is furnished by these operations and

the water rights of the Lehigh Canal are the exclusive property of this Company.

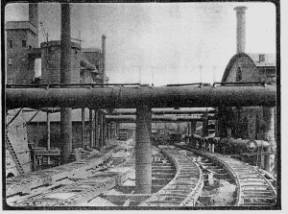

CRANE FURNACES, CATASAUQUA, PA.

Mr. John W. Thomas, the Division

Superintendent, is charged with the management of this plant. The wisdom of the

choice is confirmed by the uniformly good results obtained.

The interest of the public in the Crane

Iron Works is not limited to their importance as an industrial establishment,

nor by the measure of their influence in building up a thriving town, but

extends to the broader field in which they are considered as the outgrowth of

the first commercially successful attempt to manufacture iron by the use of

anthracite coal in America. The story of this incalculably valuable manufacturing triumph and of the Crane Iron Works properly

begins in the far off country of the Wales to which the world indebted for a

vast deal of its progress in the line of the sterner industrial arts.

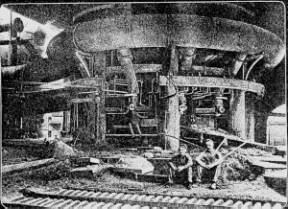

"WAITING FOR A CAST," v CRANE IRON WORKS,

CATASAUQUA, PA.

David

Thomas, who may be regarded as the father of the anthracite iron manufacture of

America, was born in South Wales, Nov. 3rd, 1794, and entered the iron business

in 1812. After working in various places he went in 1817, to the Yniscedwin

Works, Brecknockshire, located on the southern edge of an anthracite coal basin

the only one in the island of Great Britain. As early as 1820 Mr. Thomas with

George Crane, one third owner of the Yniscedwin Works, began to experiment with

anthracite, burning it in small proportions with coke, but not with practical

success. In 1825 he had a small furnace built twenty five feet high, with nine

feet bosh, which was put in blast with coke and increased amounts of

anthracite, but the experiments were not promising, and had to be abandoned. In

1830 the same furnace was made forty-five feet high with eleven feet bosh.

Attempts were again made to discover tile secret of success, and with better

results than formerly, but still it was so unprofitable that the work was again

abandoned.

During the time that Thomas and Crane

were experimenting in Wales, similar attempts were being made in the United

States with equal unsuccess. In the year 1825, Josiah White and Erskine Hazard,

both of Philadelphia, being largely interested in the mining of anthracite coal

in the then recently opened Lehigh basin, and having successfully used this

coal in the manufacture of iron wire at their mill near the Falls of

Schuylkill, erected a small furnace at Mauch Chunk, for the purpose of

experimenting as to the practicability of smelting iron with this coal. Among

other methods tried was that of passing the blast through a room heated as hot

as possible with common iron stoves. They soon abandoned this furnace and

erected a new one, in which they used charcoal exclusively, thus acknowledging

their effort to have been a failure though it contained the unrecognized

suggestion of the true and afterwards successful method. In Wales, David

Thornas was still toiling on persistently and patiently to discover the

mystery. A key to unlock it was furnished in 1834 by Neilson, manager of tile

Glascow Gas Works, who discovered the use of the hot blast. Its value was not

immediately fully appreciated. The pamphlet on the hot blast, issued by Mr.

Neilson, was read by David Thomas, who had been on the alert and perused all of

the treatises on iron manufacture and the combustion of anthracite which he

could find. One evening, while sitting with Mr. Crane in his library talking

the matter over, he took the bellows and began to blow the anthracite fire in

the grate. "You had better not, David," said Mr. Crane, "You

will blow it out," and Thomas replied, "If we only had Neilson's hot

blast here the anthracite would burn like pine." Mr. Crane said

"David, 'that is an idea." In fact it was the origin of the

application of the hot blast in making iron with anthracite. In September, 1836,

Thomas went to work, with Crane's consent, and built ovens for heating the

blast. On February 5th, 1837, the new process was applied. The result was a

success in a far greater degree them the two men had dared to hope after their

many disappointments, and from that time on there was no difficulty in making

iron with anthracite as fuel. Tile news of the success was spread over the

kingdom. The London Mining Journal gave it great prominence, and its account

appeared in the press of the United States.

In

the great anthracite region of Pennsylvania, able and enterprising men were in

readiness to utilize this valuable discovery. In 1838 the Lehigh Coal and

Navigation Co. had offered to many persons who would establish a furnace, lay

out $10.000, arid run successfully on anthracite coal exclusively for three

months the valuable water privileges extending from the Hokendauqua to the

Allentown dam. Under the inducement of this offer the Lehigh Crane Iron Co.,

consisting of members of the Coal and Navigation Co., was organized the same

year, with in the fall of the year Mr. Erskine Hazard, one of the leading

spirits of the company, went to Wales to engage some competent person to come

to this country in their interest, and to superintend the erection of furnaces.

He went to Mr. Crane, who recommended David Thomas. Together they went to see

him. At first he was reluctant to leave his native land, but at last,

influenced by a liberal offer and the consideration that his sons would have

better opportunities in America

than they could hope for in Wales or Great Britain, he consented, and

upon the night of the last day in the year, concluded an agreement and he

sailed for this country from Liverpool in May, 1839, on the clipper

"Roscius," which made the then unprecedented run of twenty-three days,

reaching New York June 5th. Mr. Thomas brought with him his whole family -- his

wife and five children. Before leaving England he had had the blowing machinery and casting for the hot

blast made, and all were shipped except the two cylinders, which were too large

for the hatches of the ship. So when the other machinery arrived the projectors

of the works were as badly off as if none had been sent.

There

was not at that time a foundry in the United States large enough to cast such cylinders

as were needed. There were small ones at Allentown and Bethlehem. The company

applied to the Allaire Works of New York, and the Alger of Boston, but neither

of them could bore a five-foot cylinder without enlarging their works, which

they were unwilling to do. Mr. Thomas then went to Philadelphia to the

Southwark foundry of S. V. Merrick and J. H. Towne, who enlarged their boring

machinery and made the five-foot cylinders required. Fire brick were imported

from Wales, there then being none manufactured in this country, and in August,

1839, ground was broken at Craneville

(now Catasauqua) for the first furnace. After many difficulties and

discouragements. the furnace was finally blown in at five o'clock, July 3,

1840. The ore was two-thirds hematite to one-third New Jersey magnetic. It was

blown with two and a half inch nozzles, and the blast heat was six hundred

degrees. The first run of iron was made the Fourth of July, and proved a great

success. From this time on the manufacture of iron by anthracite was

successfully conducted at the Crane Works, and continuously except for the

slight cessations common to all manufacturing.

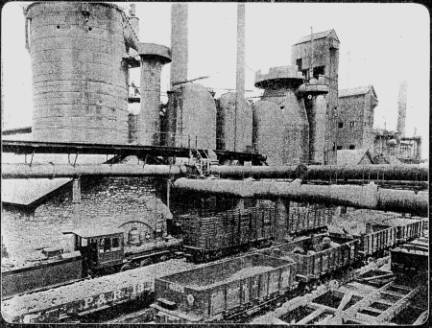

CRANE IRON WORKS, UNLOADING CARS, CATASAUQUA, PA.

Furnace

No. 1 in which the success of this new discovery was first fully demonstrated

in this country, was forty-two feet in height, with twelve feet bosh. It was

operated by a breast wheel twelve feet in diameter and twenty-four feet long,

geared by segments on its circumference to a spur wheel on a double crank,

driving two blowing cylinders, five feet in diameter, with a six-foot stroke,

worked by beams on a gallows frame. The motive power was the water of the canal

- the difference between the upper and lower levels of Lock No. 36. The furnace

remained in blast until its fires were quenched by the rising waters of the

great flood of January, 1841, a period of six months, during which one thousand

and eighty tons of pig iron were produced. The largest output for one week was

fifty-two tons. Concerning the flood, which we have mentioned, one of the

Company's old books contains the following in David Thomas' handwriting:

Furnace No. I was blown again after the

freshet, May 18, 1841, and then remained in blast until August 6th, 1842,

producing three thousand, three hundred and sixteen tons of pig iron.

A very chorus of the "I Told You

So," always unpleasant even as a solo, would have been heard by Mr. Thomas

and the members of the Crane Company had they met with failure in their

undertaking. The remark made by the leading charcoal iron master, "I will

eat all the iron you make with anthracite," gave expression to the general

sentiment of the trade at that time. It is needless to say that he did not keep

his promise, although Mr. Thomas sent him word that he had a hearty dinner

ready for him, cooked in the company's first furnace.

From that time forward the Works have

been in continued and successful operation and "Crane" Iron has

retained the enviable reputation which it speedily gained throughout the

Eastern and Middle States.

Following is a financial profile of the company

published in The Manual of Statistics, Stock Exchange Handbook in 1902

Return

to the Crane Iron Article Index

About The

Hopkin Thomas Project

Rev. June

2010